Bearings

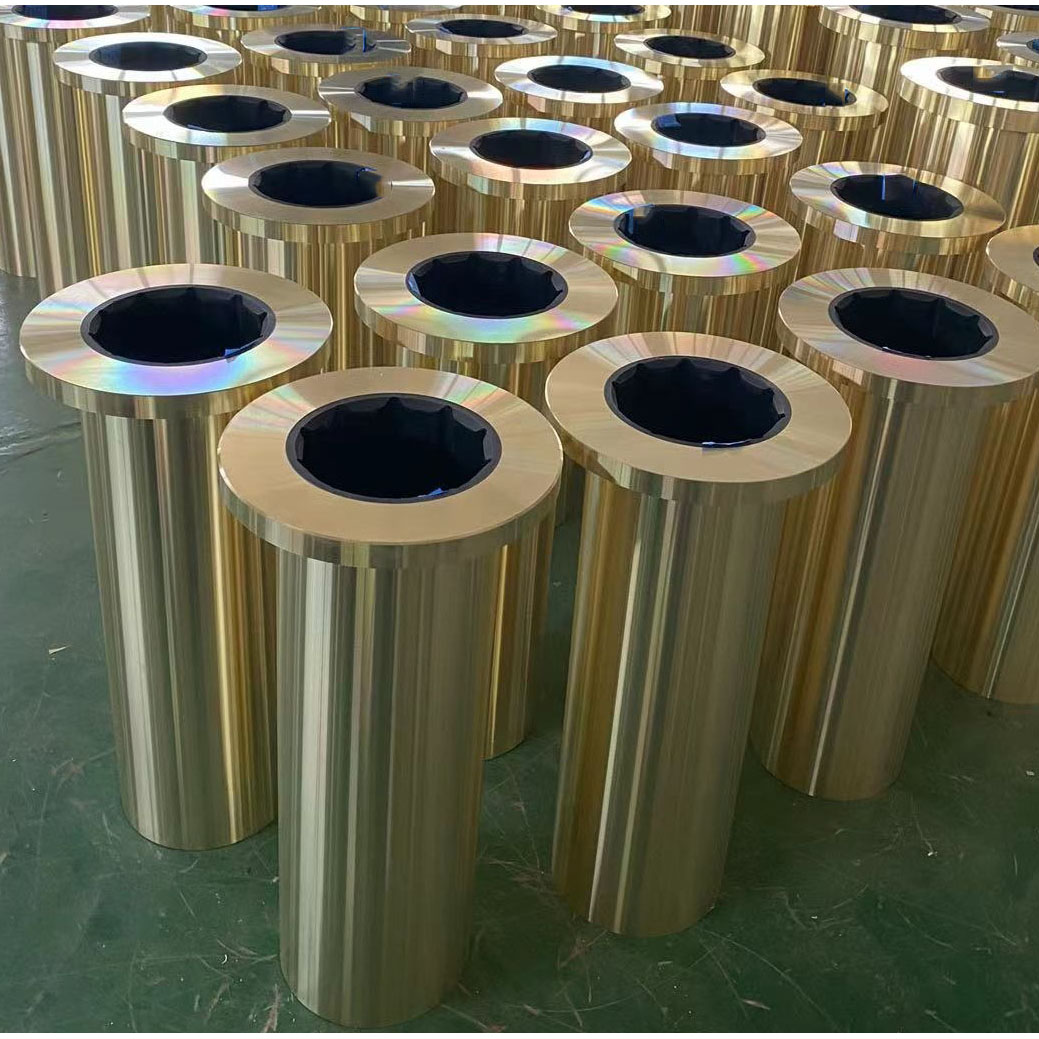

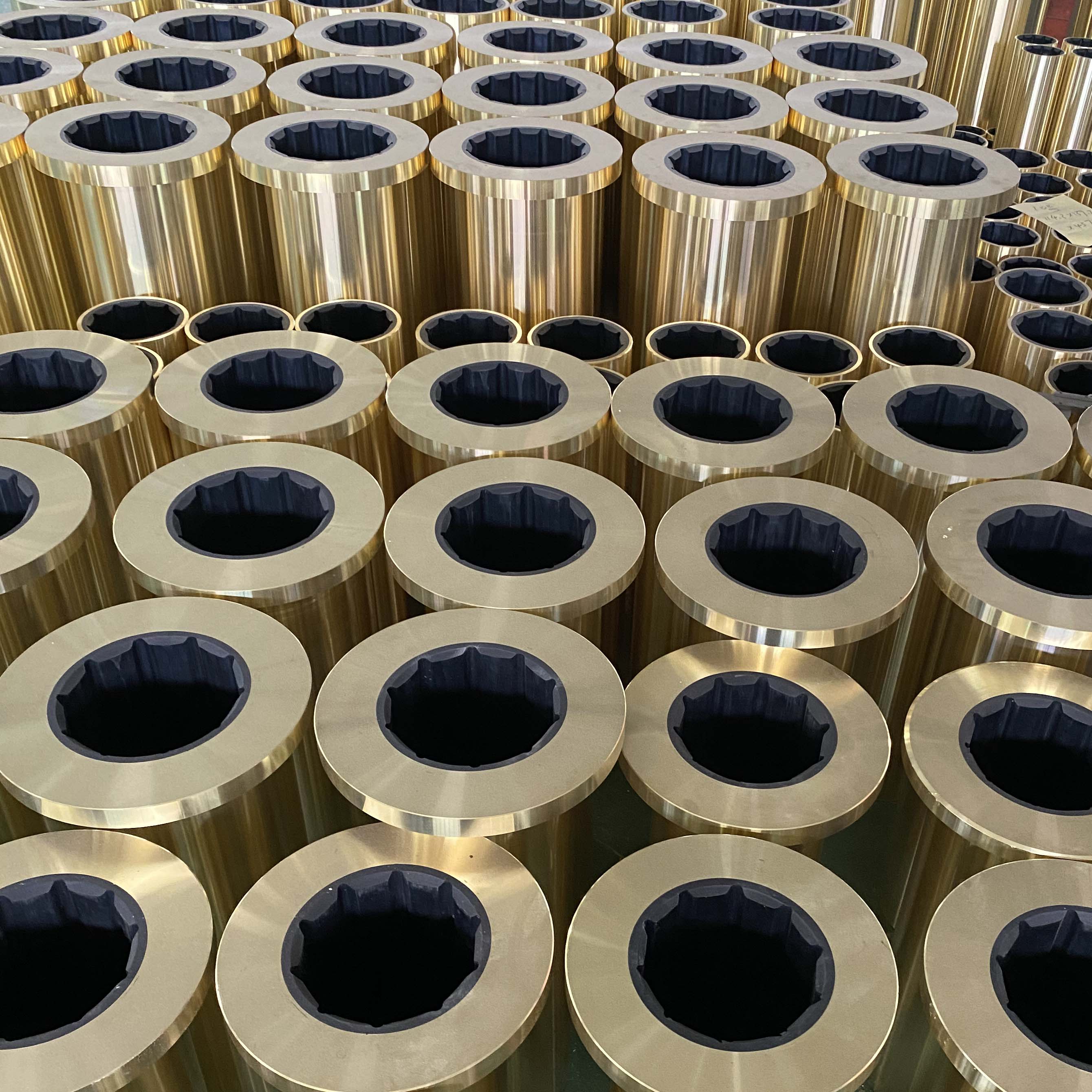

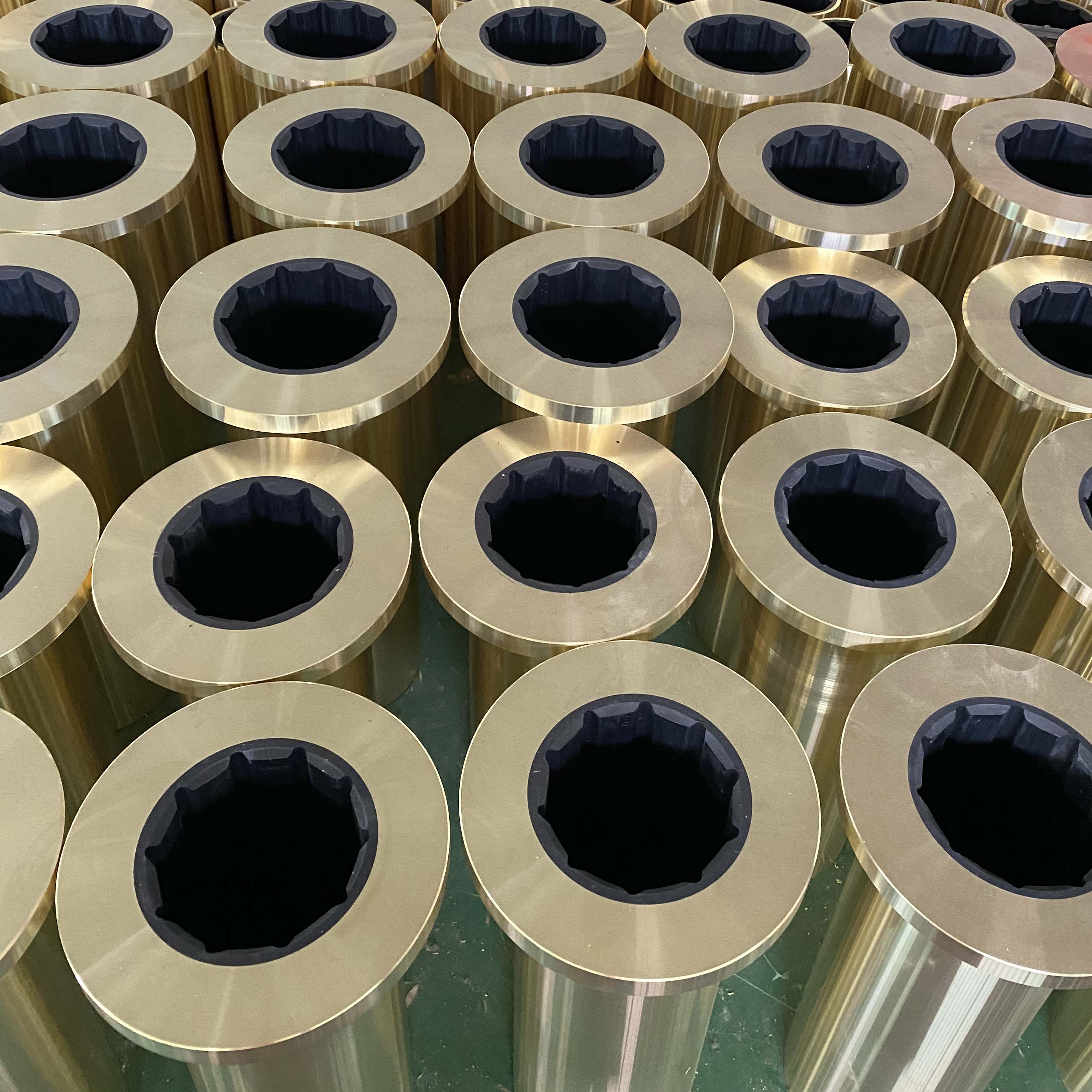

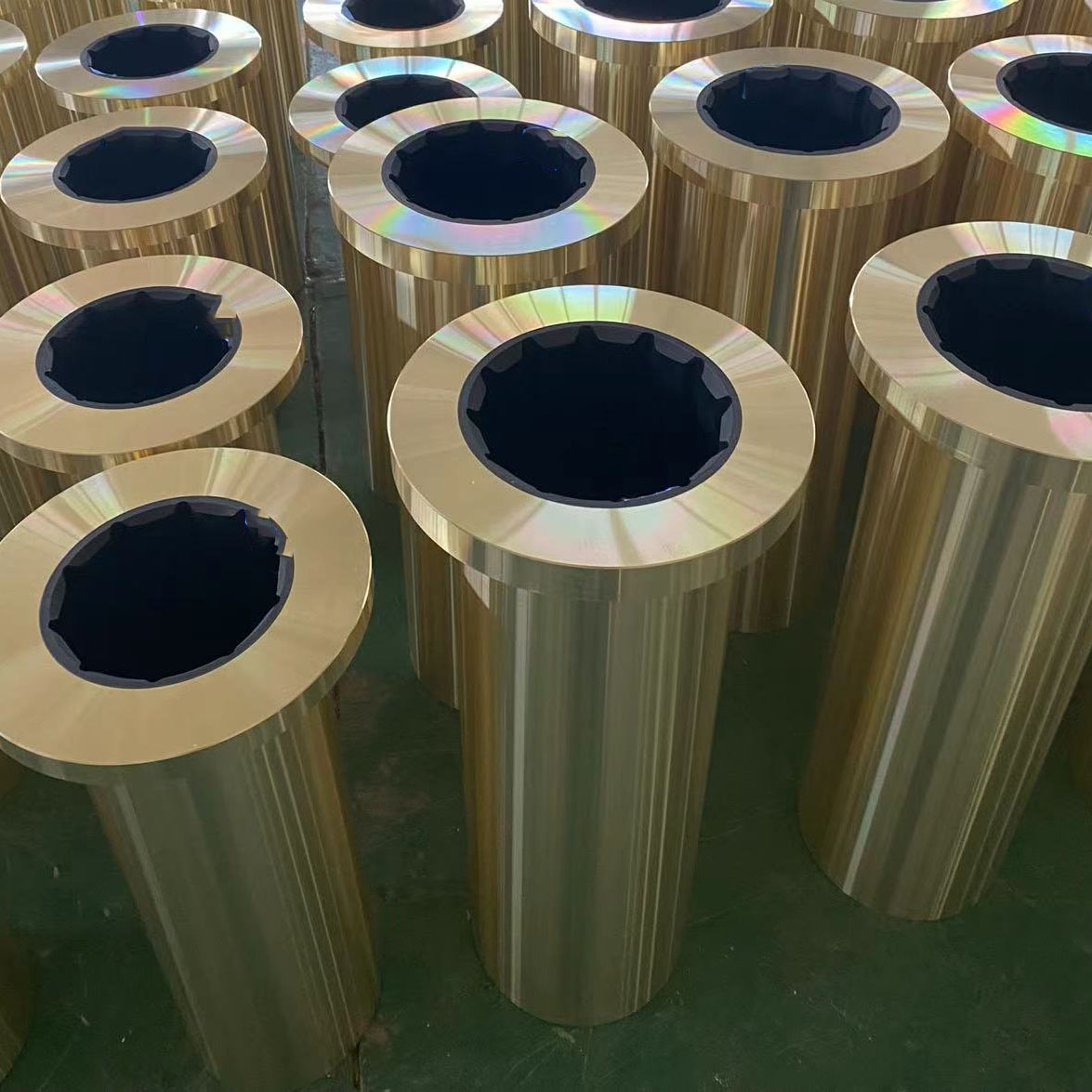

YJM cutless forward stern tube flanged bearings are made of centrifugally cast naval brass and feature a heavy metal wall and integral flange. The specially formulated nitrile rubber compound is secrely bonded to metal shell and is chemical and oil resistant. The integral flange permits solid bolting of the bearing to stern tube stuffing box. The machined male pilot on the integral flange mates with the female recess of the stuffing box. Flangeds are furnished UN-drilled unless specified.

Material

-Outer Sleeve: Brass, Bronze, or Stainless Steel

-Inner Linning: Rubber Elastomer

Structure

-Bronze Sleeve Bearing

-Bronze Flanged Bearing

-Bronze Split Bearing

Application

Metal Rubber bearings are used in

-Marine propeller stern tubes

-Cooling Water & ACW Pumps

-Rudder bearings

-Condensate Extract Pumps

-Vertical turbine Pumps

-Desalination Plant Pumps

Made

YJM Flanged Brass Stern Bearings are rubber-lined and water lubricated. They require no seals and no oil or grease for lubrication. Lubrication is provided by the water in which the vessel is traveling, making these bearings environmentally friendly. The high durability rubber liner is resistant to abrasion caused by particles in the water. The rubber is also oil and chemical resistant. The resilience of the rubber liner allows these bearings to dampen noise and vibration. The use of water as a lubricant provides efficient low friction operation and a stable lubricant film due to the water's incompressibility. The rigid outer shell is made of naval brass or non-metallic composite in the standard sleeve series. The standard flanged series outer shell is made of centrifugal cast naval brass. YJM Marine Bearings are precision molded and machined for consistently accurate dimensions and concentricity.

Products categories

Related News

-

24 . Nov, 2025

24 . Nov, 2025Discover the key benefits and applications of the seal 12x20x5, a durable, cost-effective radial shaft seal used worldwide in machinery, automotive, and renewable industries.

more... -

24 . Nov, 2025

24 . Nov, 2025Discover everything about seal 12x18x5 — from technical specs and global applications to vendors and FAQs. Ensure mechanical reliability with the right seal.

more... -

23 . Nov, 2025

23 . Nov, 2025Explore the essentials of seal 12 20 5, from definitions and specifications to global uses, benefits, and supplier comparisons. Discover why these seals are vital across industries.

more...