Products

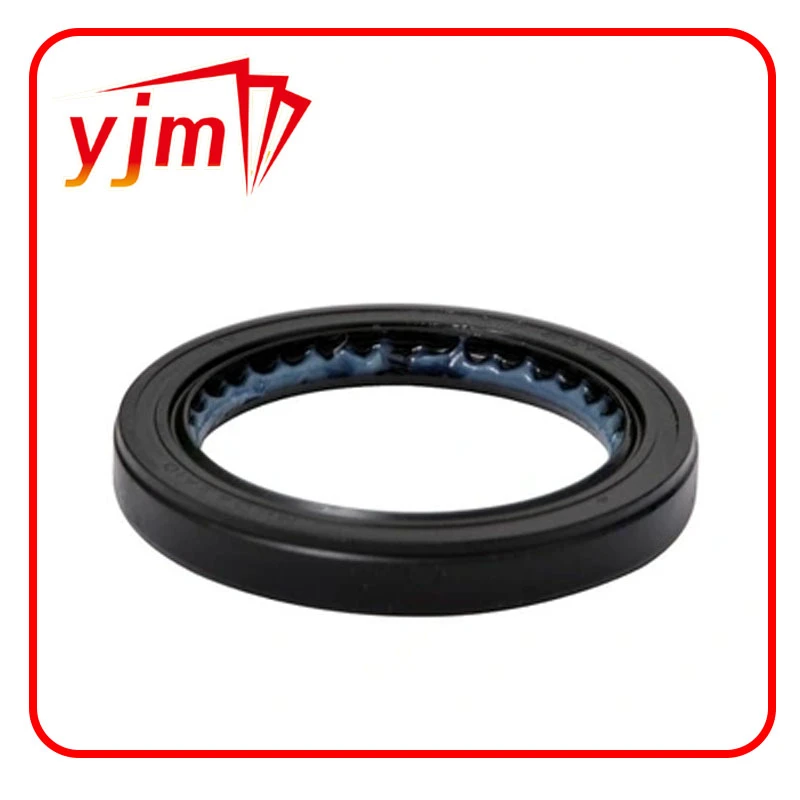

An oil seal is a crucial component used in a variety of machinery and mechanical systems to prevent the leakage of lubricants, oils, or other fluids. Typically made from materials like rubber, metal, or composite materials, oil seals are designed to fit tightly around rotating shafts, providing a barrier against contaminants and ensuring that the internal components of machinery remain lubricated and protected.

1. High Durability: Oil seals are designed to withstand high pressures and temperatures, making them ideal for use in demanding industrial applications. The material choice, whether rubber or elastomeric compounds, ensures resistance to wear and tear from friction and extreme conditions.

2. Leak Prevention: The primary function of an oil seal is to prevent oil, grease, or other fluids from leaking out of the machinery, while simultaneously blocking contaminants like dust, dirt, and moisture from entering the system. This contributes to the overall efficiency and longevity of the machinery.

3. Enhanced Seal Integrity: Oil seals are designed with multiple sealing lips or barriers that provide multiple layers of protection, ensuring minimal leakage even under high-speed operations. The advanced lip geometry also allows for effective sealing around rotating or stationary shafts.

4. Versatility: Oil seals come in various sizes, shapes, and designs to accommodate different mechanical systems. Whether it’s for automotive, industrial, or heavy machinery applications, oil seals are tailored to meet specific requirements based on shaft dimensions, operating conditions, and the type of fluid being contained.

5. Cost-Effective Maintenance: Regular inspection and timely replacement of oil seals help to maintain optimal machine performance and reduce the risk of costly repairs due to fluid leakage or contamination. Since oil seals are relatively inexpensive and easy to replace, they offer a cost-effective solution for keeping machinery running smoothly.

6. Chemical Resistance: Many oil seals are manufactured to resist specific chemicals, ensuring they can operate effectively in harsh environments like chemical processing plants, automotive engines, or hydraulic systems. This resistance to chemicals ensures that the seal maintains its integrity even when exposed to aggressive fluids.

In conclusion, oil seals are essential components that play a pivotal role in the protection and longevity of machinery. Their ability to prevent leakage, withstand harsh conditions, and protect internal components makes them indispensable in various industrial sectors.

-

-

-

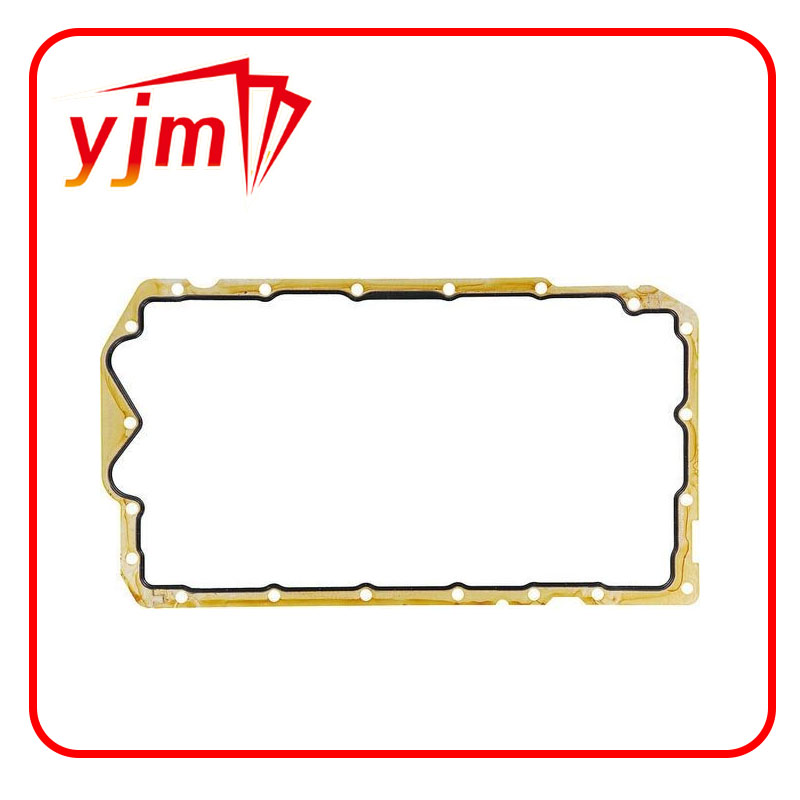

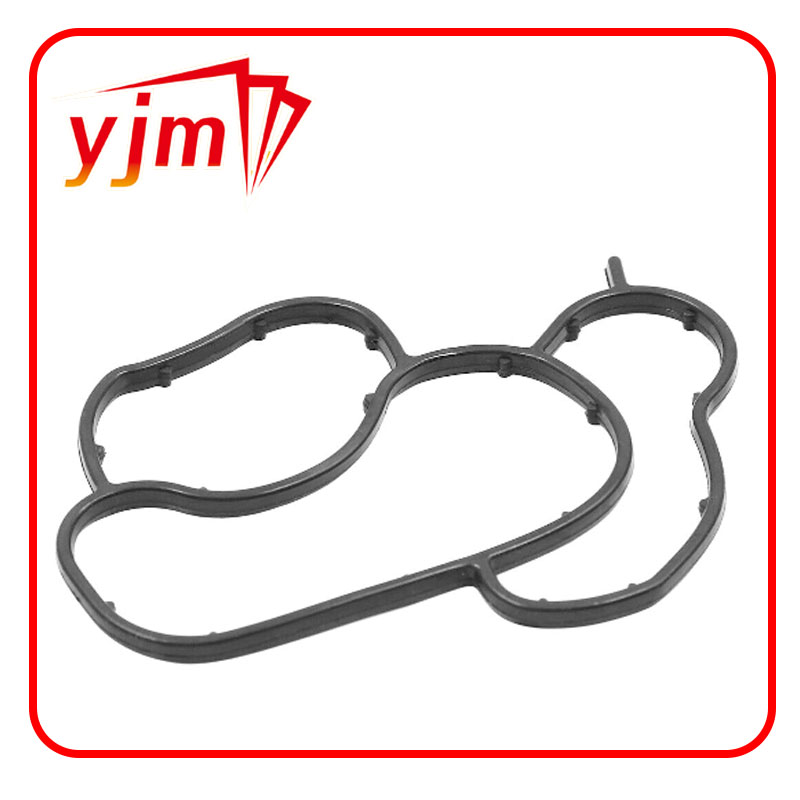

Engine Oil Cooler Filter Housing stand Gasket Seal 11427508970

-

-

-

-

-

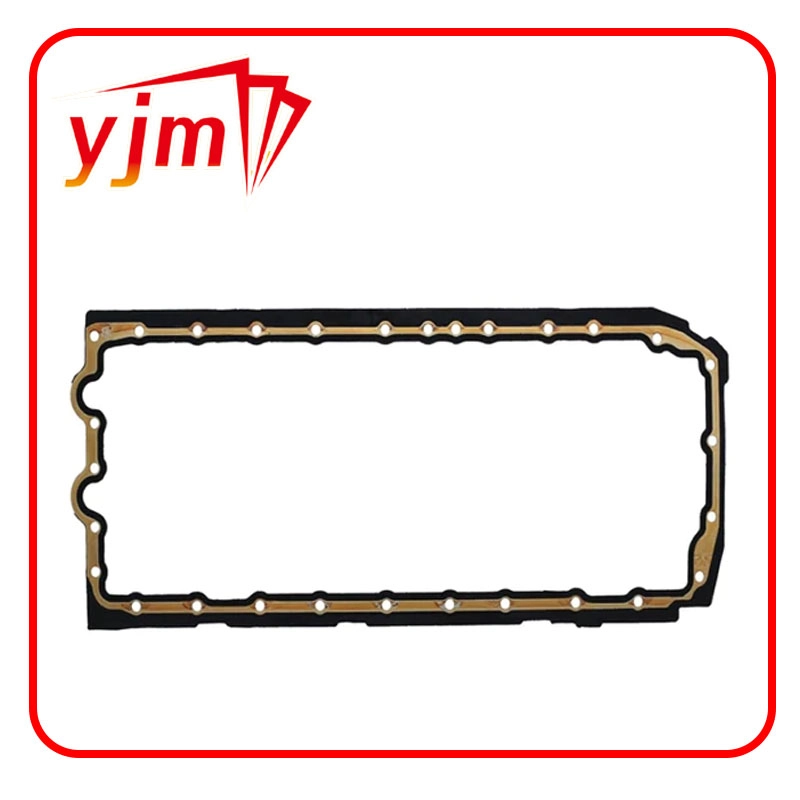

Oil Drain Plug Gaskets Crush Washers Seals Rings VW N 013 815 7

-

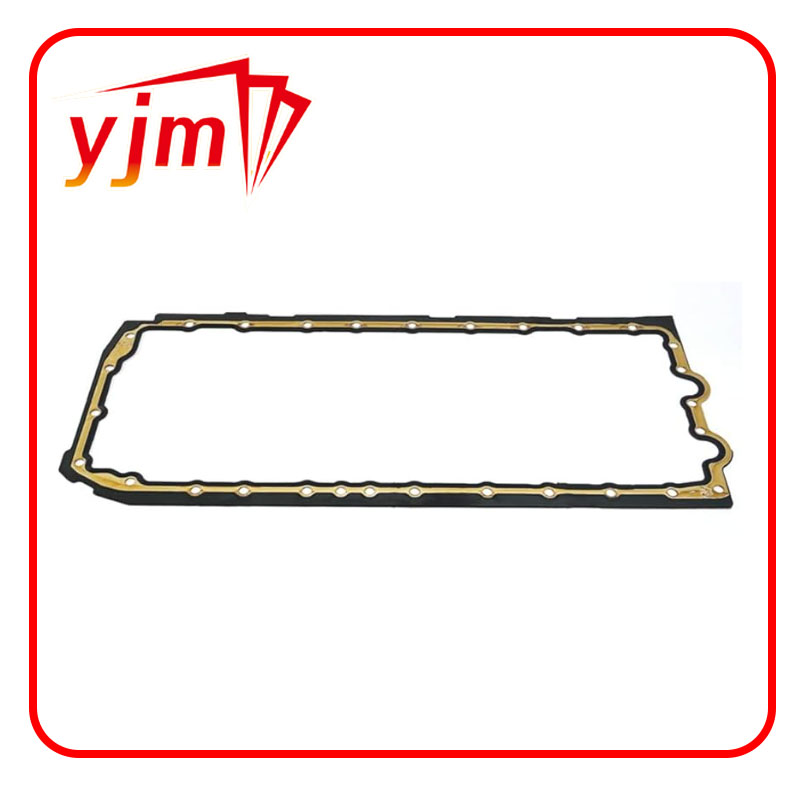

Engine Oil Drain Plug Washers Gaskets Replacement 11126-Aa000

-

-

-

How much does it cost to replace an oil seal?

The cost of replacing an oil seal can vary widely depending on several factors, including the type of machinery, the size and material of the oil seal, and the complexity of the replacement process. On average, the cost of replacing an oil seal ranges from $10 to $150 for the part itself. However, labor costs can significantly affect the total cost of replacement.

For basic applications, such as in small machinery or automotive engines, the replacement might cost around $50 to $100, which includes both parts and labor. In more complex systems, like heavy machinery, industrial equipment, or certain automotive models, the cost can rise to $200 or more due to the specialized oil seals required and the labor-intensive process of accessing the seal for replacement.

Labor charges typically range from $50 to $150 per hour, depending on the location, the complexity of the repair, and the technician's expertise. If the oil seal is difficult to access or requires the disassembly of significant parts of the machine, the labor time—and hence the total cost—can increase. For instance, replacing an oil seal on a car’s transmission may involve removing the entire transmission system, adding to the overall cost.

It's important to factor in additional costs such as diagnostic fees if you are unsure of the cause of the oil leak, as well as any necessary parts for the machinery's disassembly or reassembly.

Ultimately, regular maintenance and prompt replacement of faulty oil seals can help avoid more costly repairs down the road, ensuring the longevity and optimal performance of your machinery or vehicle.

What happens if oil seal is leaking?

If an oil seal is leaking, it can lead to a range of problems for the machinery or vehicle it is meant to protect. The primary function of an oil seal is to prevent the leakage of lubricating oils or other fluids, while also blocking contaminants from entering the system. When an oil seal starts leaking, it compromises this function, leading to several potential issues.

Firstly, a leaking oil seal can result in the loss of lubrication within the system. This can cause increased friction between moving parts, leading to faster wear and tear. Over time, this could result in severe damage to critical components like bearings, shafts, or gears, potentially leading to costly repairs or even complete system failure.

Secondly, the leakage of oil can create environmental and safety hazards. For vehicles, for example, a leaking oil seal can cause oil to drip onto the ground, posing a risk of pollution or fire, particularly in high-temperature environments. Additionally, lost oil can lower the fluid levels, reducing the system's efficiency and increasing the risk of overheating.

A leaking oil seal can also lead to contamination of the internal components. If dirt, moisture, or debris enter the system through the damaged seal, it can cause further damage or even corrosion. This can further deteriorate the performance of the machinery and reduce its lifespan.

If you notice any oil leaks or a decrease in fluid levels, it is important to replace the oil seal promptly to avoid more serious damage. Regular inspections and maintenance can help detect oil seal issues early and prevent costly repairs.