Brass Cutlass Bearings: Durable Marine Performance

The Indispensable Role of Brass Cutlass Bearings in Advanced Industrial & Marine Systems

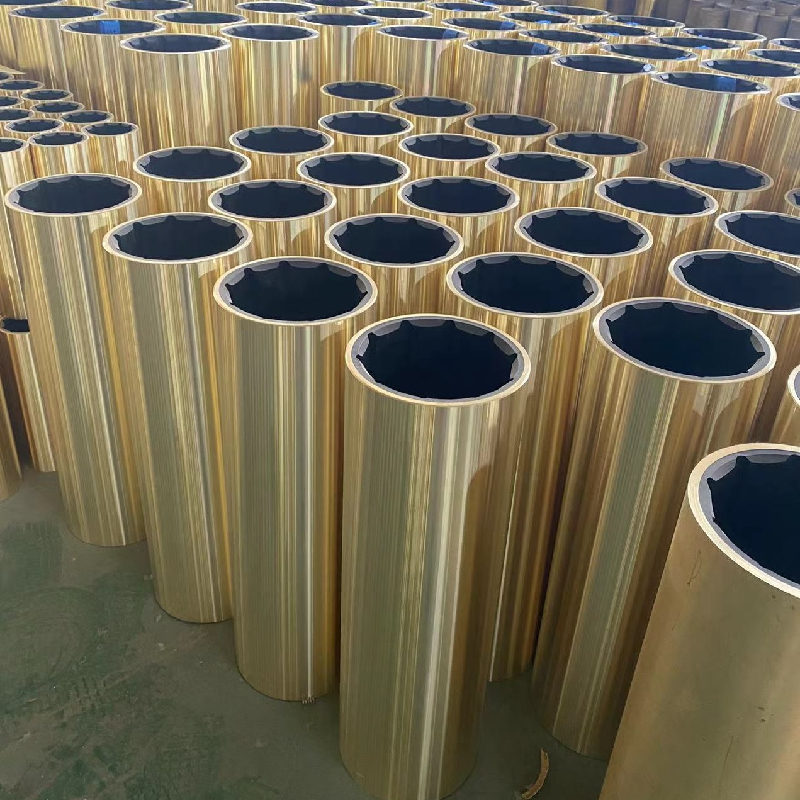

In the demanding realms of marine propulsion, industrial pumping, and critical power generation, the reliability and longevity of foundational components are paramount. Among these, the brass cutlass bearing stands as an unsung hero, a linchpin in ensuring smooth, efficient, and sustained operation of rotating shafts. These specialized bearings, often integral to stern tube assemblies, vertical pump systems, and dredging equipment, are engineered to withstand extreme conditions—ranging from highly corrosive saltwater environments to abrasive slurries and fluctuating temperatures. Their design is a sophisticated blend of material science and precision engineering, providing exceptional wear resistance, reduced friction, and robust support for propeller shafts and other critical rotating components. The evolution of cutless bearings has been driven by an incessant industry demand for enhanced durability, reduced maintenance overhead, and superior performance, particularly in applications where traditional bearing materials falter under the onslaught of cavitation, galvanic corrosion, and particulate contamination. As a leading manufacturer, YJM's Naval Brass Sleeve Bearings embody the pinnacle of this technological advancement, offering a compelling solution for sectors where operational continuity and cost-effectiveness are non-negotiable. This comprehensive exploration delves into the intricate facets of cutlass bearings marine, from their fundamental material properties and meticulous manufacturing processes to their diverse applications, technical advantages, and the stringent quality benchmarks that define their supremacy in the global market. Understanding the nuances of these bearings is crucial for engineering professionals and procurement specialists striving to optimize system performance and extend equipment lifespan in the most challenging operational contexts. This document aims to provide an exhaustive resource for stakeholders looking to leverage the full potential of high-grade brass cutlass bearing solutions.

Mastering Material Science: The Foundation of Superior Brass Cutlass Bearings

The exceptional performance of a brass cutlass bearing begins with its fundamental material composition: naval brass. Specifically, alloys such as C67600 (Lead Naval Brass) or C86400 (Manganese Bronze), or often a high-tensile Naval Brass variant, are meticulously selected for their unique combination of properties that are indispensable for severe operating conditions. Naval brass is primarily an alloy of copper and zinc, typically with minor additions of tin (Sn), lead (Pb), and sometimes manganese (Mn) or nickel (Ni), each element contributing synergistically to the overall performance profile. For instance, the copper content (typically around 59-62%) provides excellent corrosion resistance, particularly in saline environments, inhibiting degradation that would rapidly compromise ferrous metals. Zinc enhances strength and ductility, while the judicious addition of tin significantly improves resistance to dezincification—a selective leaching process common in brass alloys exposed to certain aqueous media—and further enhances corrosion resistance and strength. Lead, when present in alloys like C67600, improves machinability without detrimentally affecting other mechanical properties, allowing for the precise manufacturing of complex geometries and tight tolerances critical for optimal bearing performance. Manganese bronze (C86400), a subset often categorized under high-strength naval brass, offers even greater tensile strength and superior wear resistance, making it suitable for applications subjected to higher loads or abrasive conditions. The microstructure of these alloys, typically a duplex alpha-beta phase, contributes to their high strength and toughness. This careful selection and precise alloying are crucial, as they dictate the bearing's ability to withstand sustained loads, resist abrasive wear from suspended particles in the fluid medium, and endure aggressive chemical environments without succumbing to pitting, crevice corrosion, or stress corrosion cracking. Unlike some composite or polymeric cutless bearings, the inherent rigidity and structural integrity of naval brass provide robust support against shaft deflection and vibration, minimizing dynamic imbalance and extending the lifespan of the entire rotating assembly. The strategic choice of a specific naval brass alloy directly impacts the bearing’s life cycle cost, operational efficiency, and overall reliability, making it a critical differentiator in high-stakes industrial and cutlass bearings marine applications. The metallurgy behind each brass cutlass bearing is not merely a matter of material selection but a testament to advanced engineering principles applied to meet the most rigorous industry demands.

Furthermore, understanding the galvanic compatibility of naval brass with other metals in the system is vital for preventing accelerated corrosion, especially in saltwater applications where the bearing may be in close proximity to stainless steel shafts or bronze propellers. Naval brass exhibits good galvanic compatibility with common marine alloys, minimizing the risk of adverse electrochemical reactions. Its inherent lubricity, particularly when water-lubricated as is common for cutlass bearings, ensures low friction coefficients and minimizes heat generation during operation. This self-lubricating characteristic, combined with its high thermal conductivity, allows for efficient dissipation of frictional heat, preventing thermal expansion and potential seizing, even under heavy loads or high rotational speeds. This comprehensive approach to material science ensures that each brass cutlass bearing functions as a highly durable and reliable component, reducing downtime and maintenance expenditures across a broad spectrum of critical machinery. The ability of these bearings to operate effectively in challenging conditions, often submerged in abrasive or corrosive media, is a direct result of decades of research and development in optimizing naval brass alloys for bearing applications, setting them apart from conventional bearing solutions.

Furthermore, understanding the galvanic compatibility of naval brass with other metals in the system is vital for preventing accelerated corrosion, especially in saltwater applications where the bearing may be in close proximity to stainless steel shafts or bronze propellers. Naval brass exhibits good galvanic compatibility with common marine alloys, minimizing the risk of adverse electrochemical reactions. Its inherent lubricity, particularly when water-lubricated as is common for cutlass bearings, ensures low friction coefficients and minimizes heat generation during operation. This self-lubricating characteristic, combined with its high thermal conductivity, allows for efficient dissipation of frictional heat, preventing thermal expansion and potential seizing, even under heavy loads or high rotational speeds. This comprehensive approach to material science ensures that each brass cutlass bearing functions as a highly durable and reliable component, reducing downtime and maintenance expenditures across a broad spectrum of critical machinery. The ability of these bearings to operate effectively in challenging conditions, often submerged in abrasive or corrosive media, is a direct result of decades of research and development in optimizing naval brass alloys for bearing applications, setting them apart from conventional bearing solutions.

The Meticulous Manufacturing Process of High-Performance Brass Cutlass Bearings

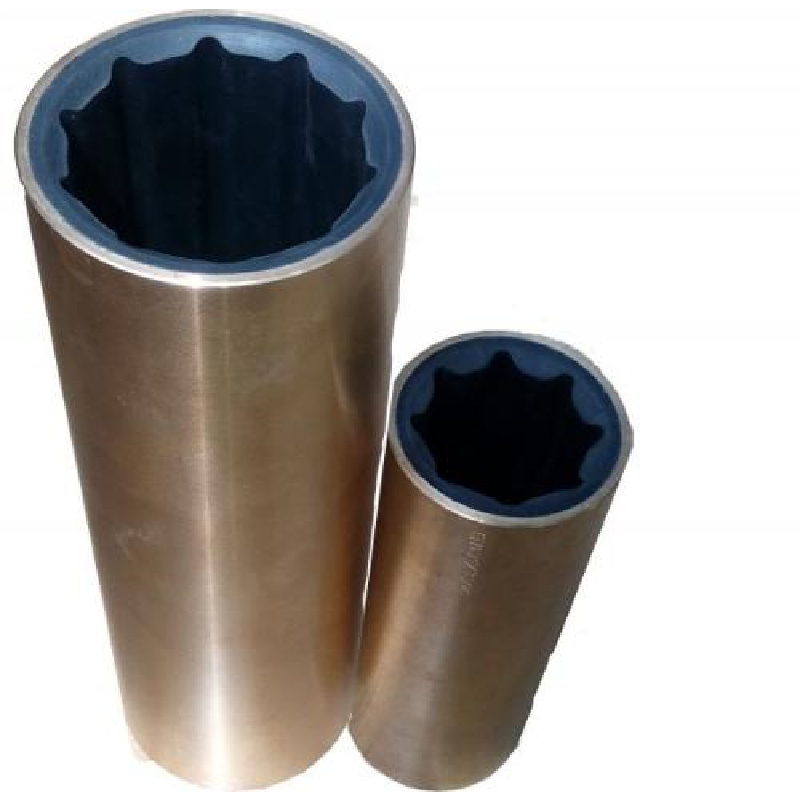

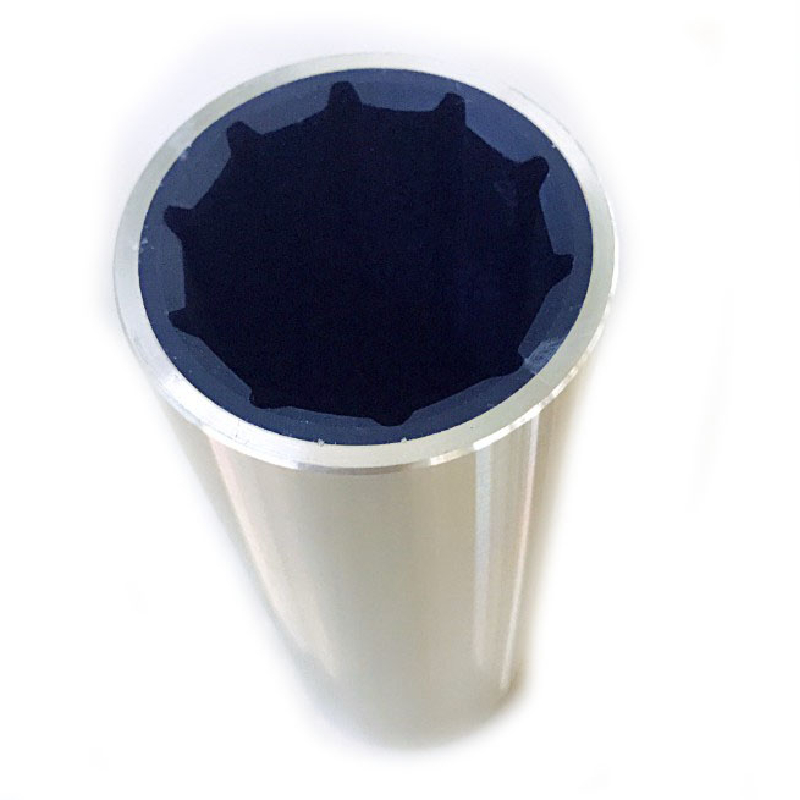

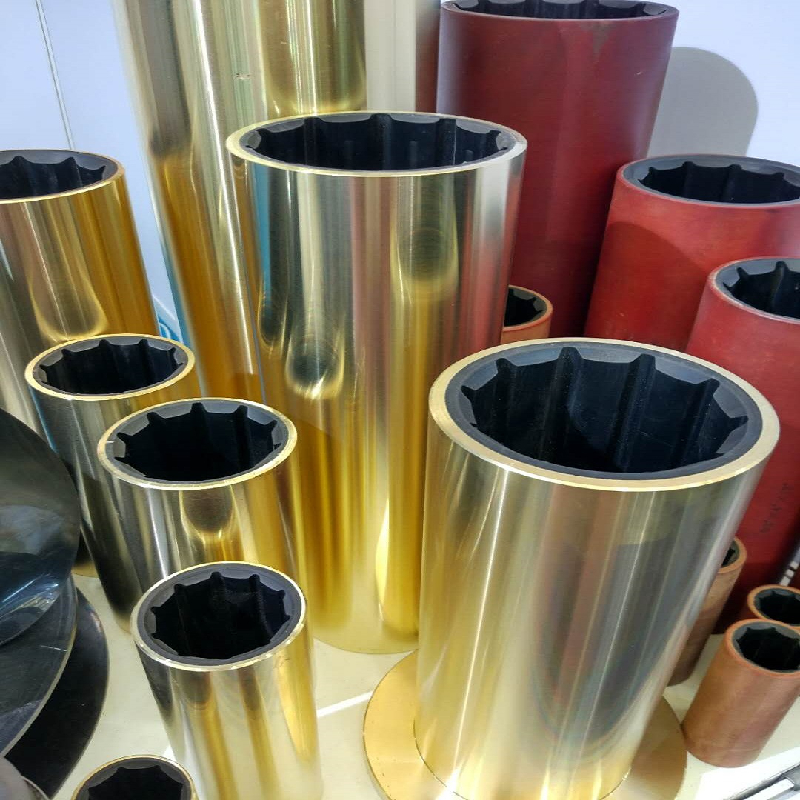

The production of a high-performance brass cutlass bearing is an intricate process demanding rigorous adherence to precision engineering and quality control, ensuring each product meets the exacting standards required for its demanding applications. The journey begins with the selection of premium-grade Naval Brass ingots or billets, chosen based on specific alloy compositions (e.g., C67600, C86400) to match the intended operational environment and load requirements. This initial material verification is crucial, often involving spectroscopic analysis to confirm elemental composition and ensure metallurgical integrity. Following material selection, the primary shaping phase typically involves either casting or forging. Large-diameter bearings may undergo centrifugal casting, which produces a denser, more uniform grain structure with minimal porosity, enhancing mechanical strength and wear resistance. Smaller bearings or those requiring superior toughness might be forged, a process that refines the grain structure and eliminates internal defects, resulting in a stronger, more ductile product. The chosen method is critical to the bearing's ultimate structural integrity and lifespan. After the initial forming, the raw blank undergoes rough machining on advanced CNC lathes, where excess material is removed, bringing the bearing close to its desired outer and inner dimensions. This preliminary machining prepares the component for subsequent precision operations and ensures efficient material utilization. The core of the manufacturing process lies in precision CNC machining. Multi-axis CNC machines are utilized to achieve exceptionally tight dimensional tolerances (e.g., ISO H7 for bore diameter, G6 for outer diameter), ensuring perfect fitment with the shaft and housing. This stage involves meticulous operations such as boring, turning, milling (for keyways or specialized mounting features), and chamfering. The accuracy achieved here directly impacts the bearing's ability to minimize vibration, prevent shaft misalignment, and maintain a consistent lubricating film, whether water, oil, or grease. Surface finish is also critical; a smooth, low-Ra (roughness average) bore reduces friction and wear on the shaft.

Beyond the physical shaping, a series of stringent quality control measures are integrated throughout the manufacturing process. These typically include dimensional inspections using calibrated instruments (micrometers, bore gauges, coordinate measuring machines - CMMs), hardness testing (Brinell or Rockwell) to verify mechanical properties, and non-destructive testing (NDT) such as ultrasonic testing or dye penetrant inspection to detect any internal flaws or surface cracks that could compromise performance. Material traceability is maintained from the raw ingot to the finished brass cutlass bearing, often adhering to standards like ISO 9001, ANSI, and ASTM B21 for Naval Brass. This comprehensive quality assurance framework guarantees that each bearing not only meets but often exceeds industry specifications, ensuring optimal performance and extended service life. The lifespan of a properly manufactured and installed cutless bearings marine component can extend for many years, significantly reducing maintenance cycles and operational costs. These bearings are predominantly used in industries such as marine (propeller shafts, rudder stock), petrochemical (vertical pumps, agitators), metallurgy (cooling beds, conveyor systems), and water/wastewater treatment (submersible pumps, clarifiers). Their inherent design and manufacturing precision lead to significant advantages, including reduced energy consumption due to lower friction, enhanced corrosion resistance in harsh environments, and superior vibration dampening capabilities. The meticulous engineering and production standards applied to every brass cutlass bearing are what distinguish a reliable component from a potential point of failure in critical operational infrastructure.

Beyond the physical shaping, a series of stringent quality control measures are integrated throughout the manufacturing process. These typically include dimensional inspections using calibrated instruments (micrometers, bore gauges, coordinate measuring machines - CMMs), hardness testing (Brinell or Rockwell) to verify mechanical properties, and non-destructive testing (NDT) such as ultrasonic testing or dye penetrant inspection to detect any internal flaws or surface cracks that could compromise performance. Material traceability is maintained from the raw ingot to the finished brass cutlass bearing, often adhering to standards like ISO 9001, ANSI, and ASTM B21 for Naval Brass. This comprehensive quality assurance framework guarantees that each bearing not only meets but often exceeds industry specifications, ensuring optimal performance and extended service life. The lifespan of a properly manufactured and installed cutless bearings marine component can extend for many years, significantly reducing maintenance cycles and operational costs. These bearings are predominantly used in industries such as marine (propeller shafts, rudder stock), petrochemical (vertical pumps, agitators), metallurgy (cooling beds, conveyor systems), and water/wastewater treatment (submersible pumps, clarifiers). Their inherent design and manufacturing precision lead to significant advantages, including reduced energy consumption due to lower friction, enhanced corrosion resistance in harsh environments, and superior vibration dampening capabilities. The meticulous engineering and production standards applied to every brass cutlass bearing are what distinguish a reliable component from a potential point of failure in critical operational infrastructure.

Key Technical Parameters and Performance Metrics for Optimal Brass Cutlass Bearings

Selecting the appropriate brass cutlass bearing necessitates a thorough understanding of its key technical parameters and performance metrics, which collectively dictate its suitability for specific applications and its expected operational lifespan. Central to these specifications are the dimensions: Inner Diameter (ID), Outer Diameter (OD), and Length. The ID must precisely match the shaft diameter with appropriate running clearance (often in the range of 0.001-0.002 inches per inch of shaft diameter) to facilitate lubrication and accommodate thermal expansion, while the OD ensures a secure press fit into the housing. Precision in these dimensions, often manufactured to ISO H7 or G6 tolerances, is critical for minimizing shaft eccentricity and preventing undue vibration or wear. Load capacity, categorized into static and dynamic, is another paramount parameter, indicating the maximum weight or force the bearing can withstand without permanent deformation or premature wear. This is often expressed in terms of radial and axial load ratings, calculated based on the bearing material’s yield strength and the projected bearing area. Operating temperature range defines the ambient and operational temperature limits within which the bearing can perform effectively without material degradation or loss of structural integrity; naval brass alloys typically perform well across a wide range, from sub-zero to moderately elevated temperatures. The PV value (Pressure-Velocity) is a crucial performance metric representing the product of bearing pressure (P) and surface velocity (V), serving as an indicator of the bearing’s ability to dissipate heat and resist wear. A higher PV limit signifies better performance under combined load and speed conditions. The friction coefficient, particularly under hydrodynamic lubrication (water-lubricated for cutlass bearings marine), directly impacts energy efficiency; lower coefficients indicate less power loss and reduced heat generation.

Hardness (Brinell or Rockwell scale) indicates the material's resistance to indentation and abrasive wear, a higher hardness generally correlating with greater durability in abrasive environments. Corrosion resistance, especially against seawater and other aggressive chemicals, is inherent to naval brass and is often validated through standardized salt spray tests (e.g., ASTM B117) or exposure to specific chemical agents, ensuring the brass cutlass bearing maintains its integrity throughout its service life. The expected lifespan is a critical economic and operational consideration, influenced by all the above factors, as well as proper installation, lubrication, and maintenance practices. Manufacturers often provide estimated lifespans based on typical operating conditions and test data. Understanding these parameters is vital for engineers to specify the correct cutless bearings for their applications, preventing premature failures and optimizing system performance. For example, for a high-speed marine propeller shaft, a bearing with a high PV limit and excellent wear resistance is essential, while for a heavily loaded industrial pump, high load capacity and robust material hardness are prioritized. YJM's stringent testing protocols, which align with international standards such as ISO, ASTM, and ANSI, ensure that every brass cutlass bearing produced adheres to these critical performance benchmarks, guaranteeing reliability and longevity for the most demanding industrial and marine operations. This meticulous attention to technical detail underscores our commitment to delivering superior bearing solutions.

Hardness (Brinell or Rockwell scale) indicates the material's resistance to indentation and abrasive wear, a higher hardness generally correlating with greater durability in abrasive environments. Corrosion resistance, especially against seawater and other aggressive chemicals, is inherent to naval brass and is often validated through standardized salt spray tests (e.g., ASTM B117) or exposure to specific chemical agents, ensuring the brass cutlass bearing maintains its integrity throughout its service life. The expected lifespan is a critical economic and operational consideration, influenced by all the above factors, as well as proper installation, lubrication, and maintenance practices. Manufacturers often provide estimated lifespans based on typical operating conditions and test data. Understanding these parameters is vital for engineers to specify the correct cutless bearings for their applications, preventing premature failures and optimizing system performance. For example, for a high-speed marine propeller shaft, a bearing with a high PV limit and excellent wear resistance is essential, while for a heavily loaded industrial pump, high load capacity and robust material hardness are prioritized. YJM's stringent testing protocols, which align with international standards such as ISO, ASTM, and ANSI, ensure that every brass cutlass bearing produced adheres to these critical performance benchmarks, guaranteeing reliability and longevity for the most demanding industrial and marine operations. This meticulous attention to technical detail underscores our commitment to delivering superior bearing solutions.

Typical Brass Cutlass Bearing Specifications (Illustrative)

| Parameter | Typical Range / Value | Unit | Notes |

|---|---|---|---|

| Material Grade | Naval Brass (C67600, C86400) | ASTM Standard | Excellent corrosion and wear resistance |

| Inner Diameter (ID) | 25 - 600+ | mm | Customizable to shaft size |

| Outer Diameter (OD) | 40 - 700+ | mm | Designed for press fit in housing |

| Length | 50 - 2000+ | mm | Application-specific |

| Hardness | 60 - 95 | HB (Brinell) | Indicates wear resistance |

| Tensile Strength | 310 - 550 | MPa | Resistance to breaking under tension |

| Operating Temperature | -30 to +80 | °C | Typical range for water-lubricated bearings |

| Coefficient of Friction (Water) | 0.005 - 0.02 | (Dimensionless) | Low friction for efficiency |

| Standards Compliance | ISO 9001, ANSI, ASTM, ABS, DNV GL | Certifications | Ensures quality and performance |

Diverse Application Scenarios and Evolving Industry Trends for Brass Cutlass Bearings

The versatility and robust performance of the brass cutlass bearing make it an indispensable component across a multitude of heavy-duty industrial and marine applications, where reliability under severe operating conditions is non-negotiable. In the marine sector, cutlass bearings marine are perhaps most famously deployed in propeller shaft and rudder post systems, specifically within stern tubes and strut housings. Here, they serve as critical water-lubricated bearings, supporting the massive rotational forces of the propeller shaft while minimizing friction and absorbing vibration. Their inherent corrosion resistance to saltwater makes them ideal for this perpetually submerged role, providing long-term stability and reducing the risk of catastrophic shaft damage or excessive wear. From commercial cargo vessels, naval ships, and cruise liners to smaller fishing boats and luxury yachts, the reliance on durable cutless bearings ensures smooth propulsion and steering. Beyond marine vessels, these bearings are extensively utilized in industrial pumps, particularly vertical turbine pumps and centrifugal pumps employed in demanding environments such as wastewater treatment plants, power generation facilities, and mining operations. In these applications, the bearings often operate submerged in abrasive slurries or corrosive chemicals, making the wear resistance and chemical compatibility of naval brass crucial. The design allows for continuous flushing by the pumped fluid, which acts as a lubricant and cooling agent, making them remarkably efficient and low-maintenance. Hydropower turbines also leverage the robustness of brass cutlass bearing technology, where they support large, slow-rotating shafts under immense hydraulic forces, contributing to the efficient conversion of water power into electricity with minimal energy loss due to friction.

In the oil and gas industry, cutlass bearings find their place in subsea equipment, offshore drilling rigs, and transfer pumps, where they must perform reliably despite extreme pressures, corrosive hydrocarbons, and abrasive seabed sediments. Their ability to withstand such harsh conditions without requiring frequent lubrication or maintenance is a significant operational advantage in remote or inaccessible locations. Dredging equipment, essential for maintaining waterways and extracting minerals, also heavily relies on the durability of brass cutlass bearing assemblies to support cutter heads and dredge pumps operating in highly abrasive sand, gravel, and mud mixtures. The wear resistance of naval brass is particularly beneficial here, mitigating the erosive effects of particulate matter. Furthermore, emerging sectors like renewable energy, particularly tidal stream turbines, are increasingly adopting robust brass cutlass bearing solutions. These turbines operate in extremely challenging marine environments, requiring bearings that can endure strong currents, biofouling, and continuous cyclical loads with minimal environmental impact. The overarching industry trends indicate a growing demand for bearings with even higher efficiency, extended mean time between failures (MTBF), and integration with smart monitoring systems for predictive maintenance. There's also a significant push towards environmentally friendly solutions, including the use of water-lubricated bearings to eliminate potential oil spills and the development of more sustainable manufacturing practices. As industrial operations become more complex and environmental regulations stricter, the evolution of brass cutlass bearing technology continues to focus on enhancing durability, reducing ecological footprint, and improving overall system reliability, positioning YJM at the forefront of these innovations.

In the oil and gas industry, cutlass bearings find their place in subsea equipment, offshore drilling rigs, and transfer pumps, where they must perform reliably despite extreme pressures, corrosive hydrocarbons, and abrasive seabed sediments. Their ability to withstand such harsh conditions without requiring frequent lubrication or maintenance is a significant operational advantage in remote or inaccessible locations. Dredging equipment, essential for maintaining waterways and extracting minerals, also heavily relies on the durability of brass cutlass bearing assemblies to support cutter heads and dredge pumps operating in highly abrasive sand, gravel, and mud mixtures. The wear resistance of naval brass is particularly beneficial here, mitigating the erosive effects of particulate matter. Furthermore, emerging sectors like renewable energy, particularly tidal stream turbines, are increasingly adopting robust brass cutlass bearing solutions. These turbines operate in extremely challenging marine environments, requiring bearings that can endure strong currents, biofouling, and continuous cyclical loads with minimal environmental impact. The overarching industry trends indicate a growing demand for bearings with even higher efficiency, extended mean time between failures (MTBF), and integration with smart monitoring systems for predictive maintenance. There's also a significant push towards environmentally friendly solutions, including the use of water-lubricated bearings to eliminate potential oil spills and the development of more sustainable manufacturing practices. As industrial operations become more complex and environmental regulations stricter, the evolution of brass cutlass bearing technology continues to focus on enhancing durability, reducing ecological footprint, and improving overall system reliability, positioning YJM at the forefront of these innovations.

Unrivaled Technical Advantages of YJM Naval Brass Sleeve Bearings

YJM's Naval Brass Sleeve Bearings, a premier offering in the realm of brass cutlass bearing technology, deliver a suite of unparalleled technical advantages that set them apart in demanding industrial and marine applications. Foremost among these is their superior corrosion resistance, especially in saline environments. Unlike many ferrous alloys or even some bronze variants, the specific composition of naval brass (e.g., high copper content, balanced zinc, and tin) used in our bearings provides exceptional immunity to the corrosive effects of seawater, brackish water, and numerous industrial chemicals. This intrinsic property significantly extends the bearing’s operational life, preventing premature failure due to rust, pitting, or galvanic degradation, which is a common concern for cutlass bearings marine. This resistance is verified through rigorous salt spray testing and long-term submersion tests, ensuring steadfast performance in the harshest conditions. Coupled with corrosion resistance is an outstanding wear resistance. The inherent hardness and robust microstructure of Naval Brass contribute to its ability to withstand abrasive particles commonly found in water or process fluids, such as sand, silt, or manufacturing residues. This minimizes material loss from the bearing surface and reduces wear on the mating shaft, leading to fewer component replacements and significantly lower maintenance costs over the equipment’s lifecycle. Our brass cutlass bearing solutions maintain their precise dimensional integrity even after prolonged exposure to abrasive media.

Furthermore, YJM's cutless bearings offer high load-bearing capacity. The exceptional compressive strength and rigidity of naval brass allow these bearings to support substantial radial and axial loads without deformation, making them ideal for heavy-duty applications like supporting large propeller shafts or high-pressure pump impellers. This robust load capacity contributes directly to the stability of rotating machinery, minimizing shaft deflection and mitigating issues like vibration and cavitation. Related to this, their excellent vibration dampening characteristics contribute to smoother operation and reduced noise levels. The inherent material properties of brass help absorb and dissipate vibrational energy, protecting the shaft and surrounding machinery from fatigue and extending the life of other connected components. When water-lubricated, as is typical for brass cutlass bearing applications, they also exhibit favorable self-lubricating properties under boundary lubrication conditions, even if the hydrodynamic film momentarily breaks down. This characteristic reduces the risk of seizing or excessive wear during start-up or low-speed operation. From an economic perspective, the extended durability and minimal maintenance requirements of YJM’s Naval Brass Sleeve Bearings translate into superior cost-effectiveness over their operational lifespan. Reduced downtime for repairs and replacements, combined with lower energy consumption due to optimized friction, yields significant long-term savings. Our commitment to precision manufacturing and material quality ensures that each brass cutlass bearing delivers reliable, energy-efficient, and long-lasting performance, offering a compelling value proposition for discerning industrial and marine clients seeking to enhance the robustness and efficiency of their critical systems.

Furthermore, YJM's cutless bearings offer high load-bearing capacity. The exceptional compressive strength and rigidity of naval brass allow these bearings to support substantial radial and axial loads without deformation, making them ideal for heavy-duty applications like supporting large propeller shafts or high-pressure pump impellers. This robust load capacity contributes directly to the stability of rotating machinery, minimizing shaft deflection and mitigating issues like vibration and cavitation. Related to this, their excellent vibration dampening characteristics contribute to smoother operation and reduced noise levels. The inherent material properties of brass help absorb and dissipate vibrational energy, protecting the shaft and surrounding machinery from fatigue and extending the life of other connected components. When water-lubricated, as is typical for brass cutlass bearing applications, they also exhibit favorable self-lubricating properties under boundary lubrication conditions, even if the hydrodynamic film momentarily breaks down. This characteristic reduces the risk of seizing or excessive wear during start-up or low-speed operation. From an economic perspective, the extended durability and minimal maintenance requirements of YJM’s Naval Brass Sleeve Bearings translate into superior cost-effectiveness over their operational lifespan. Reduced downtime for repairs and replacements, combined with lower energy consumption due to optimized friction, yields significant long-term savings. Our commitment to precision manufacturing and material quality ensures that each brass cutlass bearing delivers reliable, energy-efficient, and long-lasting performance, offering a compelling value proposition for discerning industrial and marine clients seeking to enhance the robustness and efficiency of their critical systems.

Manufacturer Comparison and Strategic Partner Selection for Brass Cutlass Bearings

The selection of a manufacturing partner for brass cutlass bearing solutions is a critical decision that profoundly impacts operational reliability, cost-efficiency, and long-term system performance. When evaluating potential suppliers, discerning buyers in the B2B sector must look beyond mere pricing and consider a holistic set of criteria that signify true expertise, authoritativeness, and trustworthiness. Firstly, certifications are non-negotiable. Reputable manufacturers of cutless bearings should possess ISO 9001 quality management certification, indicating a commitment to consistent quality and continuous improvement. For marine applications, endorsements from classification societies like ABS (American Bureau of Shipping), DNV GL, Lloyd's Register, or Bureau Veritas are paramount, as these signify that the cutlass bearings marine meet stringent industry safety and performance standards for vessel construction and operation. YJM proudly holds such relevant certifications, underscoring our dedication to global quality benchmarks. Experience and reputation are equally vital. A manufacturer with decades of experience in producing brass cutlass bearing solutions demonstrates a proven track record, deep understanding of material science, and refined manufacturing processes. Their reputation, often reflected in long-standing client relationships and positive industry feedback, speaks volumes about their product reliability and customer service. YJM, with over two decades of specialized expertise in high-performance bearings, exemplifies this experience, translating into a profound understanding of diverse application challenges and tailored solutions. Customization capabilities are another key differentiator. Many applications require unique bearing dimensions, material variations, or specialized features that off-the-shelf products cannot accommodate. A top-tier manufacturer should possess robust design and engineering capabilities, including CAD modeling and FEA (Finite Element Analysis) expertise, to develop bespoke brass cutlass bearing solutions that precisely meet specific project requirements, optimizing performance and integration.

Investment in Research & Development (R&D) is indicative of a forward-thinking manufacturer committed to innovation. Companies that continuously invest in new materials, advanced manufacturing techniques, and performance testing are better positioned to offer cutting-edge cutless bearings that address evolving industry needs, such as enhanced wear resistance, lower friction, or improved environmental compatibility. After-sales support, including technical assistance, troubleshooting, and warranty provisions, is crucial for long-term operational peace of mind. A reliable partner offers comprehensive support, ensuring that clients can maximize the lifespan and efficiency of their brass cutlass bearing installations. Finally, material sourcing and traceability are vital for ensuring product integrity and preventing counterfeit components. A transparent supply chain, from raw material procurement to final product delivery, guarantees the authenticity and quality of the Naval Brass used in each bearing. By meticulously evaluating these criteria, clients can forge strategic partnerships with manufacturers like YJM, who not only supply high-quality brass cutlass bearing products but also provide the technical expertise, trusted support, and innovation necessary to enhance their operational excellence and maintain competitive advantage. This strategic approach to supplier selection transforms a transactional purchase into a collaborative relationship, yielding significant long-term benefits in reliability and performance for critical machinery across marine and industrial sectors.

Investment in Research & Development (R&D) is indicative of a forward-thinking manufacturer committed to innovation. Companies that continuously invest in new materials, advanced manufacturing techniques, and performance testing are better positioned to offer cutting-edge cutless bearings that address evolving industry needs, such as enhanced wear resistance, lower friction, or improved environmental compatibility. After-sales support, including technical assistance, troubleshooting, and warranty provisions, is crucial for long-term operational peace of mind. A reliable partner offers comprehensive support, ensuring that clients can maximize the lifespan and efficiency of their brass cutlass bearing installations. Finally, material sourcing and traceability are vital for ensuring product integrity and preventing counterfeit components. A transparent supply chain, from raw material procurement to final product delivery, guarantees the authenticity and quality of the Naval Brass used in each bearing. By meticulously evaluating these criteria, clients can forge strategic partnerships with manufacturers like YJM, who not only supply high-quality brass cutlass bearing products but also provide the technical expertise, trusted support, and innovation necessary to enhance their operational excellence and maintain competitive advantage. This strategic approach to supplier selection transforms a transactional purchase into a collaborative relationship, yielding significant long-term benefits in reliability and performance for critical machinery across marine and industrial sectors.

Manufacturer Comparison: Key Differentiators for Brass Cutlass Bearings

| Feature/Criteria | Manufacturer A (Generic) | Manufacturer B (Generic) | YJM (Naval Brass Sleeve Bearings) |

|---|---|---|---|

| ISO 9001 Certification | Yes | Yes | Yes, with audited processes |

| Classification Society Approvals (e.g., ABS, DNV GL) | Limited / Specific | Some | Comprehensive & Global |

| Customization Capabilities | Basic Dimensions | Moderate Design | Full Engineering & Bespoke Solutions |

| Material Traceability & Sourcing | Standard | Good | Rigorous, certified supply chain |

| Technical Support & After-sales | Standard | Responsive | Dedicated, expert engineering team |

| Product Performance (Wear/Corrosion) | Meets Minimum | Good Performance | Superior, exceeding industry benchmarks |

| Typical Lead Times | Varies widely | Moderate | Optimized & Consistent |

Tailored Customization Solutions and Impactful Application Cases

In the highly specialized domains where brass cutlass bearing solutions are deployed, a one-size-fits-all approach is rarely sufficient. The unique operational envelopes, varied shaft dimensions, and specific environmental challenges of marine vessels, industrial pumps, and power generation systems necessitate tailored customization solutions to ensure optimal performance and longevity. YJM excels in providing bespoke cutless bearings, leveraging extensive engineering capabilities and advanced manufacturing processes to meet the precise requirements of each client. The customization process typically begins with an in-depth consultation, where our experienced engineering team collaborates with clients to understand their specific application, operating conditions (including temperature, load, speed, and fluid medium), existing machinery configurations, and any historical performance issues with previous bearing solutions. This comprehensive data gathering forms the foundation for design and engineering. Utilizing state-of-the-art CAD modeling software, detailed 2D and 3D designs of the custom brass cutlass bearing are developed, allowing for precise visualization and fitment verification. For particularly complex or high-stress applications, Finite Element Analysis (FEA) is employed to simulate real-world stresses, strains, and thermal performance, ensuring the design will withstand anticipated loads and operational dynamics. This analytical rigor minimizes risks and optimizes material utilization. Material selection is also customized; while naval brass is the core, specific alloys (e.g., C67600 for machinability, C86400 for higher strength) or even composite liners within a naval brass shell can be chosen to enhance properties like wear resistance in abrasive conditions or improve friction characteristics.

Following design approval, prototyping and rigorous testing are conducted to validate the custom brass cutlass bearing’s performance against specified parameters before full-scale production. This meticulous approach ensures that the final product seamlessly integrates into the client’s system and delivers superior performance. Our application cases vividly illustrate the impact of these tailored solutions. For instance, in a recent project involving a large commercial cargo vessel facing persistent vibration issues with its stern tube bearings, YJM designed and manufactured custom cutlass bearings marine with optimized internal geometries and a slightly adjusted material composition to better handle dynamic loads and reduce resonance. The result was a significant reduction in shaft vibration, improved fuel efficiency due to lower friction, and an estimated 30% increase in bearing lifespan, leading to substantial operational savings for the shipping company. Another notable case involved a municipal wastewater treatment plant requiring replacement bearings for a critical vertical pump operating in a highly abrasive slurry. Traditional bearings were failing prematurely due to particulate wear. YJM provided a bespoke brass cutlass bearing utilizing a specialized, harder grade of Naval Brass and incorporating optimized water grooves for improved flushing of abrasive particles. This customized solution extended the pump’s operational period by over 150% between maintenance cycles, drastically reducing downtime and maintenance costs. These examples highlight YJM's commitment to not just supplying bearings, but providing comprehensive, engineered solutions that address specific client challenges, enhance system reliability, and deliver measurable operational improvements in the most demanding environments. This client-centric approach, combined with our technical prowess, distinguishes YJM as a trusted partner for complex brass cutlass bearing requirements.

Following design approval, prototyping and rigorous testing are conducted to validate the custom brass cutlass bearing’s performance against specified parameters before full-scale production. This meticulous approach ensures that the final product seamlessly integrates into the client’s system and delivers superior performance. Our application cases vividly illustrate the impact of these tailored solutions. For instance, in a recent project involving a large commercial cargo vessel facing persistent vibration issues with its stern tube bearings, YJM designed and manufactured custom cutlass bearings marine with optimized internal geometries and a slightly adjusted material composition to better handle dynamic loads and reduce resonance. The result was a significant reduction in shaft vibration, improved fuel efficiency due to lower friction, and an estimated 30% increase in bearing lifespan, leading to substantial operational savings for the shipping company. Another notable case involved a municipal wastewater treatment plant requiring replacement bearings for a critical vertical pump operating in a highly abrasive slurry. Traditional bearings were failing prematurely due to particulate wear. YJM provided a bespoke brass cutlass bearing utilizing a specialized, harder grade of Naval Brass and incorporating optimized water grooves for improved flushing of abrasive particles. This customized solution extended the pump’s operational period by over 150% between maintenance cycles, drastically reducing downtime and maintenance costs. These examples highlight YJM's commitment to not just supplying bearings, but providing comprehensive, engineered solutions that address specific client challenges, enhance system reliability, and deliver measurable operational improvements in the most demanding environments. This client-centric approach, combined with our technical prowess, distinguishes YJM as a trusted partner for complex brass cutlass bearing requirements.

Ensuring Trust: Quality Assurance, Support, and Frequently Asked Questions (FAQ) for Brass Cutlass Bearings

Building and maintaining trust with clients, especially in the B2B sector, is paramount. At YJM, our commitment to delivering superior brass cutlass bearing solutions is underpinned by a rigorous multi-faceted approach to quality assurance, comprehensive customer support, and transparent communication, including addressing common inquiries through a dedicated FAQ module. Our quality assurance process begins even before manufacturing, with stringent raw material inspection. Every batch of Naval Brass undergoes detailed chemical analysis (e.g., spectrometer testing) and mechanical property verification (e.g., tensile strength, hardness) to ensure it meets our exacting specifications and relevant industry standards like ASTM B21. Throughout the manufacturing process of each cutless bearings component, multiple in-process quality checks are conducted, including dimensional inspections using precision CMMs and gauges, surface finish measurements, and visual inspections for any defects. Post-machining, a final comprehensive inspection takes place, often including non-destructive testing (NDT) such as ultrasonic testing for internal integrity or eddy current testing for surface flaw detection. This meticulous cradle-to-grave quality control ensures that every brass cutlass bearing leaving our facility conforms to the highest standards of precision, durability, and performance, and our ISO 9001 certification provides an independent verification of these robust quality management systems. Each product is traceable back to its raw material batch and manufacturing record, offering complete accountability.

Our commitment extends beyond product delivery with robust customer support and comprehensive warranty provisions. YJM offers a standard warranty on all our Naval Brass Sleeve Bearings, reflecting our confidence in their quality and longevity. Specific terms and conditions are clearly outlined, providing peace of mind to our clients regarding their investment. Our dedicated technical support team, comprising experienced engineers, is readily available to assist with installation guidance, troubleshooting, maintenance recommendations, and any operational queries related to cutlass bearings marine. This proactive support minimizes downtime and optimizes the performance of our bearings in real-world applications. Regarding logistics, we understand the critical nature of timely delivery in industrial operations. YJM has established an efficient global supply chain and logistics network, enabling reliable and consistent delivery cycles. Our lead times are transparently communicated and our team works diligently to meet project deadlines, ensuring minimal disruption to client operations. For urgent requirements, expedited shipping options are often available. To further enhance trustworthiness and provide immediate answers to common concerns, we have compiled a Frequently Asked Questions (FAQ) section specifically for brass cutlass bearing applications:

Our commitment extends beyond product delivery with robust customer support and comprehensive warranty provisions. YJM offers a standard warranty on all our Naval Brass Sleeve Bearings, reflecting our confidence in their quality and longevity. Specific terms and conditions are clearly outlined, providing peace of mind to our clients regarding their investment. Our dedicated technical support team, comprising experienced engineers, is readily available to assist with installation guidance, troubleshooting, maintenance recommendations, and any operational queries related to cutlass bearings marine. This proactive support minimizes downtime and optimizes the performance of our bearings in real-world applications. Regarding logistics, we understand the critical nature of timely delivery in industrial operations. YJM has established an efficient global supply chain and logistics network, enabling reliable and consistent delivery cycles. Our lead times are transparently communicated and our team works diligently to meet project deadlines, ensuring minimal disruption to client operations. For urgent requirements, expedited shipping options are often available. To further enhance trustworthiness and provide immediate answers to common concerns, we have compiled a Frequently Asked Questions (FAQ) section specifically for brass cutlass bearing applications:

- What is the typical lifespan of a YJM Naval Brass Sleeve Bearing?

The lifespan varies significantly based on operating conditions (load, speed, water quality, maintenance), but with proper installation and ideal conditions, our brass cutlass bearing can last for many years, often exceeding a decade in marine and industrial applications. Regular inspection and shaft alignment are key to maximizing longevity. - Are these bearings suitable for applications other than marine?

Absolutely. While commonly known as cutlass bearings marine, our Naval Brass Sleeve Bearings are extensively used in various industrial sectors, including water & wastewater treatment, petrochemical, hydropower, mining, and dredging, wherever robust water-lubricated or abrasive-resistant bearings are required. - Can YJM provide custom sizes or designs?

Yes, customization is a core strength. We offer full engineering design services to produce bespoke brass cutlass bearing solutions tailored to unique dimensions, specific material requirements, or challenging operational environments. Contact our sales team with your specifications. - What maintenance do these bearings require?

Generally, brass cutlass bearing requires minimal maintenance, primarily ensuring adequate water flow for lubrication and cooling, and periodic inspection for wear. They are inherently designed for reliability and extended operational periods. Unlike oil-lubricated bearings, they eliminate the need for grease or oil replenishment. - How do these bearings handle abrasive environments?

Our Naval Brass Sleeve Bearings are engineered for high wear resistance. The hardness of the naval brass combined with specific design features, such as water grooves, allows them to effectively manage abrasive particles, flushing them out and minimizing their impact on bearing surfaces and shafts.

Conclusion: YJM's Leadership in Brass Cutlass Bearing Technology

The journey through the intricate world of the brass cutlass bearing underscores its critical importance in ensuring the longevity, efficiency, and reliability of vital rotating machinery across the marine, industrial, and energy sectors. From the meticulous selection of high-grade Naval Brass alloys to the precision of CNC machining and rigorous adherence to international quality standards, every step in the manufacturing of YJM's Naval Brass Sleeve Bearings is geared towards delivering unparalleled performance. We have explored how the inherent properties of naval brass — superior corrosion resistance, exceptional wear resistance, high load-bearing capacity, and remarkable vibration dampening — position the brass cutlass bearing as the preferred choice for environments characterized by harsh conditions, abrasive media, and continuous operation. The detailed analysis of industry trends highlights a growing emphasis on sustainability, enhanced efficiency, and integrated condition monitoring, all areas where YJM is actively innovating to push the boundaries of bearing technology. Our commitment to providing tailored customization solutions, supported by advanced engineering and validated through impactful application cases, ensures that our clients receive not just a product, but a precisely engineered solution optimized for their unique operational challenges. The emphasis on robust quality assurance, comprehensive customer support, transparent warranty policies, and clear communication through our FAQ section reinforces YJM's unwavering dedication to building enduring trust with our B2B partners.

As industries continue to evolve, demanding higher levels of performance, greater energy efficiency, and minimal environmental impact, the role of reliable components like cutlass bearings marine will only become more pronounced. YJM remains at the forefront of this evolution, continuously investing in R&D, refining our manufacturing processes, and expanding our expertise to address future challenges. Our mission is to empower industrial and marine operations worldwide with cutless bearings that not only meet but exceed expectations, contributing to safer, more efficient, and more sustainable global infrastructure. Choosing YJM for your brass cutlass bearing needs means partnering with a leader in material science and precision engineering, ensuring your critical systems operate with unparalleled reliability and extended service life. We invite you to experience the YJM difference – a commitment to excellence that stands the test of time and tide.

As industries continue to evolve, demanding higher levels of performance, greater energy efficiency, and minimal environmental impact, the role of reliable components like cutlass bearings marine will only become more pronounced. YJM remains at the forefront of this evolution, continuously investing in R&D, refining our manufacturing processes, and expanding our expertise to address future challenges. Our mission is to empower industrial and marine operations worldwide with cutless bearings that not only meet but exceed expectations, contributing to safer, more efficient, and more sustainable global infrastructure. Choosing YJM for your brass cutlass bearing needs means partnering with a leader in material science and precision engineering, ensuring your critical systems operate with unparalleled reliability and extended service life. We invite you to experience the YJM difference – a commitment to excellence that stands the test of time and tide.

Further Reading and Industry Insights

For those interested in delving deeper into the technical aspects and industry developments surrounding marine bearings and related materials, the following resources offer valuable insights:

- ISO 9001:2015 Quality Management Systems – Requirements - Official ISO Standard for quality management.

- ASTM B21/B21M - Standard Specification for Naval Brass Rod, Bar, and Shapes - Details the composition and properties of Naval Brass.

- Marine Bearings Guide: Cutlass, Stern Tube, and Rudder Bearings - A practical guide on marine bearing types.

- ScienceDirect - Bearing Materials - Academic resource on various bearing materials and their properties.

Please note: External links are provided for informational purposes only. YJM is not responsible for the content of external websites.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories