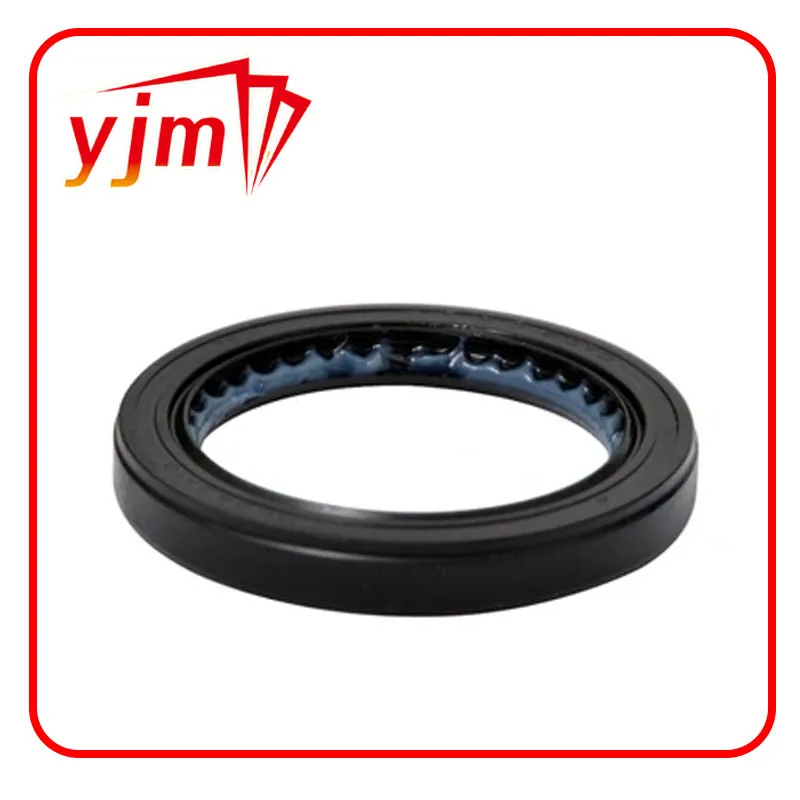

Transfer Case Input Seal: Durable Oil Seal for Leak-Free Performance

In the complex world of automotive mechanics, the integrity of every component is paramount to vehicle performance and longevity. Among these critical parts, the transfer case input seal stands as a silent guardian, preventing lubricant leakage and protecting the internal mechanisms of the transfer case. This component is not merely a piece of rubber; it is a meticulously engineered part designed to withstand extreme conditions, ensuring the smooth power transfer from the transmission to the transfer case, a vital function in four-wheel-drive and all-wheel-drive vehicles. Understanding its intricacies, from material science to manufacturing precision, is essential for anyone involved in automotive maintenance, design, or component supply.

The Indispensable Role of the Transfer Case Input Seal in Modern Drivetrains

The transfer case is a cornerstone of any 4WD or AWD system, distributing power to both the front and rear axles. The transfer case input seal acts as a crucial barrier, specifically at the point where the input shaft from the transmission enters the transfer case. Its primary function is to contain the lubricating oil within the transfer case, preventing it from escaping and simultaneously preventing contaminants like dirt, water, and debris from entering. A failure in this seal can lead to oil starvation within the transfer case, resulting in increased friction, premature wear of gears and bearings, overheating, and ultimately, catastrophic failure of the unit. Given the demanding operational environments – varying temperatures, high rotational speeds, and exposure to road elements – the design and material integrity of this oil seal are critical.

Industry Trends and Technological Advancements in Sealing Solutions

The automotive industry is continuously evolving, driven by demands for higher efficiency, reduced emissions, improved durability, and enhanced performance. These trends directly influence the development of components like the transfer case input seal. Manufacturers are increasingly moving towards:

- Advanced Materials: Beyond traditional Nitrile Butadiene Rubber (NBR) and Viton (FKM), new elastomeric compounds offer superior temperature resistance, chemical compatibility (with synthetic oils), and wear resistance. Materials like Hydrogenated Nitrile Butadiene Rubber (HNBR) and specific types of fluoropolymer elastomers are gaining prominence for their enhanced durability in harsh environments.

- Optimized Lip Designs: Innovations in lip geometry, including hydrodynamic features (helical patterns on the lip), are designed to pump oil back into the transfer case, further reducing leakage and improving seal lifespan. This also contributes to lower friction, which indirectly aids in fuel efficiency.

- Reduced Friction and NVH (Noise, Vibration, Harshness): Engineers are developing seals that minimize rotational friction, contributing to better fuel economy. Simultaneously, designs aim to dampen vibrations and reduce noise emissions, enhancing overall vehicle refinement.

- Integration of Smart Features: While still nascent for basic oil seals, the long-term trend points towards sensor integration for condition monitoring, allowing for predictive maintenance and reducing unexpected breakdowns.

- Environmental Compliance: The shift towards environmentally friendly manufacturing processes and materials that are free from harmful substances aligns with global regulatory requirements.

Deep Dive: Transfer Case Input Shaft Oil Seal Toyota 9031143008

Our featured product, the Transfer case input shaft oil seal Toyota 9031143008, exemplifies precision engineering tailored for specific OEM applications. This specific part is designed to meet the rigorous standards of Toyota vehicles, ensuring perfect fit, form, and function. Its design takes into account the specific dimensions, operating temperatures, and lubricant types found in compatible Toyota transfer cases, providing optimal sealing performance and longevity.

Key Product Specifications and Parameters

To highlight the precise engineering of such components, consider the following typical parameters for a high-quality transfer case input seal:

| Parameter | Description | Typical Value (e.g., for Toyota 9031143008) |

|---|---|---|

| Material | Often Viton (FKM) or HNBR for superior heat and chemical resistance. | High-performance FKM/HNBR blend |

| Outer Diameter (OD) | The diameter of the seal's housing side. | 60mm - 80mm (specific to application) |

| Inner Diameter (ID) | The diameter of the shaft sealing surface. | 40mm - 50mm (specific to application) |

| Width/Height | The axial dimension of the seal. | 8mm - 12mm |

| Operating Temperature Range | The range of temperatures the seal can reliably withstand. | -40°C to +150°C (FKM); -40°C to +135°C (HNBR) |

| Pressure Resistance | Ability to withstand internal pressure (often low pressure for seals). | Up to 0.5 Bar (static); Varies dynamically |

| Shaft Surface Speed | Maximum rotational speed of the shaft the seal can tolerate. | Up to 25 m/s |

| Lip Design | Single lip, double lip, or with hydrodynamic features. | Dual-lip with hydrodynamic aid for enhanced sealing |

| Spring Material | Spring that applies radial force to the sealing lip. | Stainless Steel (SUS 304/316) for corrosion resistance |

Comparison: OEM vs. Aftermarket Seals

While the Toyota 9031143008 is an OEM-specific part, understanding the broader landscape is key. When comparing seals, especially a transfer case input seal, several factors come into play:

| Feature | OEM-Specific Seal (e.g., Toyota 9031143008) | Generic Aftermarket Seal | |||

|---|---|---|---|---|---|

| Design Precision | Engineered to exact OEM specifications, often with proprietary materials and designs. Guarantees perfect fit and performance. | May be a "fits many" design, potentially compromising optimal fit or sealing efficiency. | |||

| Material Quality | Uses high-grade, often vehicle-specific, elastomers and metal components for optimal durability and chemical compatibility. | Quality varies significantly; cheaper materials may degrade faster or be incompatible with modern lubricants. | |||

| Performance Consistency | Undergoes rigorous testing by the OEM and manufacturer to ensure consistent performance over vehicle lifespan. | Less stringent testing; performance can be inconsistent. | |||

| Lifespan Expectancy | Designed to match or exceed the vehicle's expected lifespan under normal operating conditions. | Potentially shorter lifespan, leading to earlier failure and repeat repairs. | |||

| Installation Ease | Perfect fit reduces installation difficulties and the risk of damage during fitting. | May require more effort to install, increasing risk of damage or improper seating. | |||

| Warranty & Support | Typically backed by strong OEM or reputable manufacturer warranty. | Warranty coverage can be limited or non-existent, and support may be minimal. | Cost | Higher initial investment, but often offsets long-term costs through reliability. | Lower initial cost, but potential for higher overall costs due to frequent replacements or collateral damage. |

Choosing an OEM-specified part like the Toyota 9031143008 for a transfer case input seal application mitigates risks associated with inferior materials and imprecise fit, ensuring the longevity and reliability of the vehicle's drivetrain.

Manufacturing Process of a High-Performance Transfer Case Input Seal

The creation of a precision transfer case input seal is a multi-stage process that combines advanced material science with sophisticated manufacturing techniques. Here’s a detailed breakdown:

-

Design and Engineering (CAD/CAE):

The process begins with meticulous design based on OEM specifications (like for Toyota 9031143008). Engineers use Computer-Aided Design (CAD) for precise dimensioning and Computer-Aided Engineering (CAE) for simulating performance under various conditions (temperature, pressure, shaft speed). This stage also involves material selection, choosing the optimal elastomeric compound (e.g., FKM, HNBR) and metal (e.g., carbon steel, stainless steel for the spring and outer case) to meet specific requirements like temperature resistance, chemical compatibility with lubricants, and wear resistance. This ensures the seal adheres to standards like ISO 6194-1:2007 (Rotary shaft lip type seals) for general principles and dimensions.

↓

-

Material Preparation (Rubber Compounding & Metal Stamping):

For the elastomeric part, raw rubber polymers are compounded with various additives (fillers, plasticizers, curing agents, antioxidants) to achieve desired physical properties like hardness, elasticity, tensile strength, and chemical resistance. This is a critical step, as the precise formulation dictates the seal's long-term performance. Simultaneously, the metal case (often called the insert or shell) and the garter spring are prepared. The metal case is typically made via precision stamping or deep drawing of steel sheets, while the garter spring is coiled from high-grade stainless steel wire (e.g., SUS 304 or 316 for corrosion resistance) to ensure consistent radial force.

↓

-

Molding (Compression/Injection Molding):

The prepared rubber compound is then molded onto the pre-fabricated metal case. This is often done via compression molding or injection molding. In compression molding, a pre-measured amount of rubber is placed in a heated mold cavity, and pressure is applied to form the desired shape. For high-volume production and complex geometries, injection molding can be used, where heated rubber is injected into a closed mold. During this process, the rubber cures (vulcanizes), forming a strong bond with the metal insert. The precision of the mold is crucial for achieving the exact lip geometry and dimensions of the transfer case input seal.

↓

-

Finishing and Trimming:

After molding, the seals undergo deflashing and trimming to remove any excess material (flash) from the molding process. This is often done manually or with automated precision cutters to ensure clean edges and proper functionality of the sealing lips.

↓

-

Garter Spring Insertion:

The pre-formed garter spring is then carefully inserted into the groove behind the primary sealing lip. This spring provides the necessary radial force to maintain constant contact between the sealing lip and the rotating shaft, ensuring effective sealing even with minor shaft run-out or vibration.

↓

-

Quality Control and Inspection:

Every transfer case input seal undergoes stringent quality control at various stages. This includes visual inspections for defects, dimensional checks using precise calipers and optical inspection systems, and performance testing. Key tests include:

- Lip Load Test: Measuring the radial force exerted by the sealing lip.

- Torque Test: Assessing the rotational friction generated by the seal.

- Leakage Test: Simulating operating conditions to ensure no oil leakage.

- Material Property Tests: Durometer (hardness), tensile strength, elongation, and compression set tests on rubber samples to ensure they meet specifications.

Adherence to standards like ISO 9001:2015 (Quality Management Systems) and automotive-specific standards like IATF 16949 (formerly ISO/TS 16949) is critical at this stage, affirming the highest levels of quality assurance for products like the Toyota 9031143008 oil seal.

↓

-

Lubrication and Packaging:

Before packaging, some seals may receive a protective coating or a light lubrication to aid in initial installation and reduce break-in friction. Finally, the seals are carefully packaged to prevent damage during transit and storage, ensuring they arrive in pristine condition, ready for installation.

This detailed process ensures that each transfer case input shaft oil seal Toyota 9031143008 not only meets but often exceeds OEM performance expectations, contributing to vehicle reliability and driver safety.

Technical Advantages and Application Scenarios

The advantages of a high-quality transfer case input seal extend beyond mere leak prevention. When engineered with precision and manufactured with superior materials, these seals offer:

- Extended Drivetrain Lifespan: By effectively containing lubricants, the seal prevents premature wear of internal gears, bearings, and shafts, significantly extending the operational life of the transfer case and transmission.

- Reduced Maintenance Costs: Fewer leaks mean less frequent top-ups of expensive synthetic lubricants and reduced need for costly component replacements due to lubrication-related failures.

- Improved Fuel Efficiency: Modern seal designs with hydrodynamic lips and low-friction materials reduce parasitic drag on the input shaft, contributing marginally but positively to overall vehicle fuel economy.

- Enhanced Vehicle Reliability: A reliable oil seal ensures consistent power delivery and prevents unexpected breakdowns, especially critical for off-road vehicles or those used for towing.

- Superior Contaminant Exclusion: The robust design and tight fit prevent water, dirt, and road grime from entering the transfer case, protecting sensitive internal components from abrasive wear and corrosion.

- High Temperature and Chemical Resistance: Utilizing materials like FKM (Viton) ensures the seal maintains integrity even when exposed to high operating temperatures and aggressive synthetic gear oils, preventing material degradation and hardening.

- Vibration Dampening: The precise fit and material properties can help to slightly dampen minor vibrations, contributing to a smoother and quieter operation of the drivetrain, thus improving NVH characteristics.

Applicable Industries and Typical Applications

While the Toyota 9031143008 is specific to automotive applications, the principles and benefits of a high-quality transfer case input seal are mirrored across various heavy-duty and industrial sectors where rotary seals are critical:

- Automotive & Light/Heavy Duty Vehicles: Primarily for SUVs, pick-up trucks, 4x4s, commercial vans, and heavy trucks equipped with transfer cases for multi-axle power distribution.

- Construction Equipment: Earthmovers, excavators, bulldozers, and loaders often use complex drivetrains requiring robust seals to protect against dirt and debris in harsh environments.

- Agricultural Machinery: Tractors, harvesters, and other farm equipment operate in challenging conditions, relying on durable seals for power transmission components.

- Mining Vehicles: Extremely demanding environments require seals that can withstand abrasive dust, extreme temperatures, and heavy loads.

- Marine Applications: Though specific designs differ, the need for reliable shaft sealing in marine propulsion systems shares common ground with oil seal technology.

The specific advantages like corrosion resistance (due to stainless steel springs and FKM material) and energy efficiency (due to reduced friction) are highly valued across these sectors, making the underlying technology of the transfer case input seal universally beneficial where rotary power transmission requires fluid containment.

Manufacturer Capabilities and Customized Solutions

When selecting a supplier for critical components like a transfer case input seal, it's vital to consider the manufacturer's capabilities, not just product specifications. A reputable manufacturer, like YJMSEAL, stands out through:

- R&D and Engineering Expertise: Continuous investment in research and development to innovate materials and seal designs, adapting to evolving industry needs and vehicle technologies. This includes advanced simulation tools for predictive performance analysis.

- Advanced Manufacturing Facilities: State-of-the-art equipment for rubber compounding, precision molding, and automated assembly, ensuring high volume production with consistent quality.

- Rigorous Quality Assurance: Adherence to international standards like ISO 9001, and often automotive-specific standards such as IATF 16949, which signifies a commitment to the highest quality management systems in the automotive supply chain. This includes comprehensive testing from raw material inspection to final product verification.

- Global Supply Chain Management: Efficient logistics and supply networks to ensure timely delivery and responsiveness to customer demands worldwide.

- Technical Support and After-Sales Service: Providing expert advice on seal selection, installation guidelines, and troubleshooting.

Customized Sealing Solutions

While OEM parts like the Toyota 9031143008 are standard, there are scenarios where customized solutions for a transfer case input seal are necessary, particularly for:

- Legacy Vehicles/Equipment: When OEM parts are no longer available or difficult to source.

- Unique Drivetrain Modifications: Custom builds or specialized applications requiring non-standard dimensions or material properties.

- Performance Upgrades: Demanding applications that push beyond standard seal capabilities, requiring enhanced temperature, pressure, or chemical resistance.

- Cost Optimization for Volume Orders: Developing a bespoke seal that offers the required performance at a more competitive price point for large-scale industrial machinery manufacturers.

A capable manufacturer can work with clients to design and produce custom oil seal solutions, leveraging their engineering expertise to select appropriate materials (e.g., custom FKM compounds, PTFE-based materials) and optimize lip geometries for specific operating conditions, ensuring optimal sealing performance even in the most challenging scenarios.

Application Cases and Customer Success Stories

The true measure of a transfer case input seal's effectiveness lies in its real-world performance. While specific customer names cannot be disclosed due to confidentiality, here are illustrative examples of how high-quality seals contribute to success:

-

Case Study 1: Commercial Fleet Durability

A large logistics company operating a fleet of commercial delivery vans and light trucks (many equipped with AWD systems utilizing components compatible with the Toyota 9031143008 transfer case input seal) experienced recurring transfer case oil leaks with aftermarket seals. This led to increased vehicle downtime, higher maintenance costs, and concerns about safety. Upon switching to high-quality OEM-grade seals, specifically designed for their vehicle models, the incidence of leaks dropped by 95% over a two-year period. The fleet reported significantly reduced unscheduled maintenance, extended service intervals, and an overall improvement in vehicle reliability, directly translating into operational cost savings and improved delivery schedules. The robust FKM material of the seals ensured longevity even with intensive daily mileage and varied driving conditions.

-

Case Study 2: Off-Road Enthusiast Performance

An avid off-road enthusiast, frequently subjecting his modified Toyota Land Cruiser to extreme conditions (water crossings, rocky terrains, steep inclines), faced persistent issues with generic transfer case input seals failing due to extreme temperatures, dirt ingress, and shaft deflection. After upgrading to a premium oil seal that matched the OEM specifications (similar to Toyota 9031143008 but for his specific model), featuring a dual-lip design and a high-strength stainless steel garter spring, he observed a dramatic improvement. The seal consistently maintained its integrity even after numerous water fordings and high-stress maneuvers, preventing any lubricant contamination or loss. This enhanced reliability allowed him to push his vehicle further, without the constant worry of drivetrain damage.

-

Case Study 3: Industrial Pump Manufacturer

While not a transfer case, an industrial pump manufacturer faced challenges with high-speed shaft seals in their chemical processing pumps. They required seals resistant to highly corrosive fluids and extreme temperatures. A customized sealing solution, leveraging advanced elastomeric compounds and a robust metal casing similar to those used in high-performance transfer case input seals, was developed. This custom oil seal extended the pump's operational life by 300% compared to previous solutions, significantly reducing maintenance downtime and increasing productivity for their end-users in the petrochemical industry. This highlights the adaptability and superior performance of expertly engineered seals across diverse demanding applications.

These examples underscore the tangible benefits of investing in high-quality, precisely engineered sealing solutions, whether for an OEM replacement like the Toyota 9031143008 or a tailored industrial application.

FAQ: Expert Answers to Common Questions about Transfer Case Input Seals

Understanding the nuances of a transfer case input seal is crucial for proper maintenance and longevity. Here are answers to common professional questions:

-

What are the common causes of premature failure for a transfer case input seal?

Premature failure of a transfer case input seal can be attributed to several factors: age-related material degradation (hardening, cracking), excessive shaft run-out or vibration, improper installation (nicking or tearing the lip), contamination of the sealing surface (dirt, rust), extreme operating temperatures exceeding the seal's material limits, use of incompatible lubricants, or a defective seal from manufacturing.

-

How do different seal materials (e.g., NBR, FKM, HNBR) impact performance and lifespan?

The material of the oil seal significantly impacts its performance. NBR (Nitrile Butadiene Rubber) is a general-purpose material suitable for basic applications with moderate temperatures (-30°C to 100°C) and mineral oils. FKM (Fluoroelastomer, often known by the brand name Viton) offers superior resistance to high temperatures (up to 200°C), synthetic lubricants, and various chemicals, making it ideal for demanding automotive applications like the transfer case input seal. HNBR (Hydrogenated Nitrile Butadiene Rubber) provides a balance, with better heat and chemical resistance than NBR, and excellent resistance to petroleum-based oils, typically performing well up to 150°C. Choosing the right material ensures compatibility with the lubricant and operating conditions, maximizing lifespan.

-

What is a hydrodynamic lip design in an oil seal and its benefit?

A hydrodynamic lip design refers to microscopic helical or chevron patterns molded onto the sealing lip surface. As the shaft rotates, these patterns create a pumping action that actively draws a small amount of oil back into the transfer case, away from the outer edge of the seal. This mechanism significantly enhances sealing effectiveness, reduces leakage, and can extend the life of the transfer case input seal by ensuring the lubrication of the sealing interface while minimizing oil loss.

-

What are the critical installation standards or best practices for a transfer case input seal?

Proper installation is paramount for the longevity of a transfer case input seal. Key best practices include: ensuring the shaft and bore are clean, smooth, and free of burrs or scratches; using a seal installation tool to ensure the seal is pressed squarely and to the correct depth without cocking; applying a thin layer of clean lubricant (compatible with the seal material) to the shaft and sealing lip before installation; avoiding hammering directly on the seal; and always replacing worn shafts or sleeves if significant wear is present. Following OEM service manual guidelines (like for Toyota 9031143008) is crucial.

-

How does ISO/ANSI certification relate to the quality of a transfer case input seal?

ISO (International Organization for Standardization) certifications, particularly ISO 9001 (Quality Management Systems) and IATF 16949 (Quality Management System for Automotive Production), are crucial indicators of a manufacturer's commitment to quality. While not specific to the seal itself, they ensure that the design, manufacturing process, and quality control procedures meet stringent international standards. ANSI (American National Standards Institute) provides various standards, some of which may relate to dimensions or testing methods, indirectly contributing to the quality framework. For a transfer case input seal, these certifications provide assurance of consistent product quality and reliability.

-

What is the typical lifespan of a high-quality transfer case input seal, and what factors influence it?

A high-quality transfer case input seal, such as the Toyota 9031143008, designed and manufactured to OEM standards, can typically last for 100,000 to 150,000 miles or more, often throughout the useful life of the vehicle, provided proper maintenance and operating conditions. Factors influencing lifespan include: operating temperature (higher temps reduce life), shaft speed and run-out, lubricant quality and compatibility, exposure to contaminants, installation quality, and vehicle usage (e.g., severe off-road vs. highway driving).

-

Can a failing transfer case input seal affect fuel economy or vehicle performance?

Yes, indirectly. A failing transfer case input seal leads to lubricant loss from the transfer case. Insufficient lubrication increases friction within the transfer case, causing components to work harder, generating more heat, and potentially leading to premature wear. This increased drag can result in a marginal, but measurable, decrease in fuel economy due to higher parasitic losses. More critically, it can compromise the performance and long-term reliability of the 4WD/AWD system, potentially leading to a complete transfer case failure if left unaddressed.

Trustworthiness: Our Commitment to Quality and Service

At YJMSEAL, our commitment to providing top-tier sealing solutions, including the Transfer case input shaft oil seal Toyota 9031143008, is built on a foundation of trust and reliability. We understand that in the automotive industry, component failure is not an option. Our approach to trustworthiness encompasses:

- Proven Track Record: With years of experience in the precision sealing industry, we have supplied countless high-quality oil seal products to clients globally, earning a reputation for excellence and reliability.

- Strict Quality Assurance: Every transfer case input seal undergoes rigorous testing and inspection protocols, adhering to international quality standards such as ISO 9001, ensuring that each product meets precise specifications and performs optimally under demanding conditions. Our facilities are equipped with advanced testing apparatus to verify material properties, dimensions, and sealing integrity.

- Transparent Delivery Cycles: We provide clear and accurate estimated delivery times from the outset. Our robust supply chain and efficient logistics ensure that orders are processed swiftly and dispatched on schedule, minimizing downtime for our clients. For standard products like the Toyota 9031143008, we maintain optimized stock levels to facilitate rapid fulfillment.

- Comprehensive Warranty: We stand behind the quality of our products. All our seals, including the transfer case input seal, come with a comprehensive warranty against manufacturing defects. This commitment provides our customers with peace of mind, knowing that their investment is protected.

- Dedicated Customer Support: Our team of technical experts is readily available to provide pre-sales consultation, assist with product selection, offer installation guidance, and provide responsive after-sales support. We believe in building long-term partnerships through exceptional service, ensuring that our clients have the necessary expertise at their fingertips to maximize the performance and longevity of our seals.

- Authoritative Citations and Industry Recognition: We continuously engage with industry leaders and adhere to the latest engineering best practices. Our products are designed to meet or exceed OEM specifications, reflecting our authoritative stance in the sealing industry. We pride ourselves on positive customer feedback and long-standing relationships with reputable automotive and industrial partners.

Conclusion: The YJMSEAL Advantage in Sealing Excellence

The transfer case input seal is far more than a simple component; it is a vital element ensuring the durability, efficiency, and reliability of complex drivetrain systems. From preventing lubricant loss to excluding harmful contaminants, its performance directly impacts vehicle longevity and operational costs. The Transfer case input shaft oil seal Toyota 9031143008 exemplifies the precision engineering, advanced material science, and stringent quality control necessary for such critical applications.

At YJMSEAL, we are dedicated to setting the standard for sealing solutions. Our expertise spans advanced materials, innovative manufacturing processes, and rigorous quality assurance, ensuring that every oil seal we produce meets the highest benchmarks of performance and reliability. Whether it's an OEM-specific replacement or a custom-engineered solution, we prioritize customer trust through transparent processes, dependable delivery, comprehensive support, and an unwavering commitment to quality. Choosing a high-quality transfer case input seal is an investment in the long-term health and performance of your vehicle or machinery, an investment that YJMSEAL is uniquely positioned to fulfill.

References and Further Reading:

- Society of Automotive Engineers (SAE) International: SAE Journal of Automotive Drivetrain Technology - Often discusses advancements in drivetrain components and sealing technologies.

- Seal & Design Inc.: Sealing Technology Glossary and Technical Information - Provides general information on various seal types and materials.

- International Organization for Standardization (ISO): Official ISO Website - For details on ISO 9001, ISO 6194, and other relevant quality and product standards.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories