High-Quality Transfer Case Input Seal & Oil Seal Replacement

The Crucial Role of Transfer Case Input Seals in Drivetrain Integrity

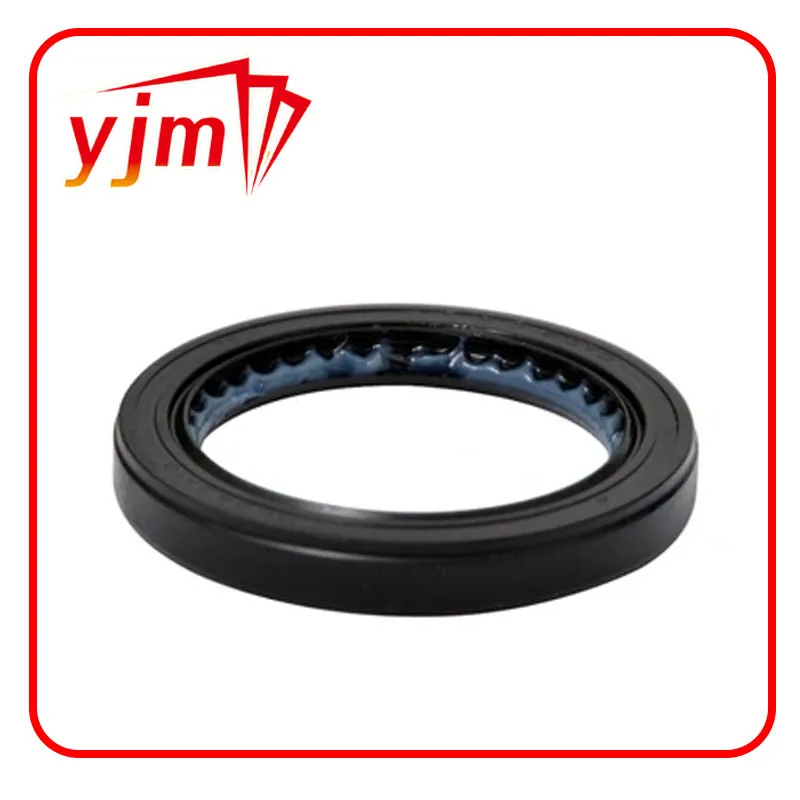

In the demanding world of automotive and heavy-duty machinery, the reliability of every component is paramount. The transfer case input seal plays a critical, yet often underestimated, role in maintaining the operational integrity of a vehicle's drivetrain. This precision-engineered component prevents the leakage of lubricating fluids from the transfer case, ensuring optimal performance and extending the lifespan of vital internal gears and bearings. A robust transfer case input seal is essential for vehicles ranging from light trucks to heavy-duty industrial equipment, where consistent power delivery and fluid retention are non-negotiable for safety and efficiency. Its design must withstand extreme temperatures, high rotational speeds, and various environmental contaminants, underscoring the need for superior material science and manufacturing precision.

Industry trends indicate a growing demand for seals that offer enhanced durability, reduced friction, and superior sealing capabilities under more severe operating conditions. As vehicles become more powerful and complex, the stresses placed on drivetrain components intensify. This necessitates advancements in oil seal technology, moving towards materials with better chemical resistance and temperature stability, and designs that minimize drag while maximizing sealing effectiveness. Manufacturers are increasingly focused on developing seals that can contribute to overall energy efficiency by reducing parasitic losses, thereby aligning with global sustainability initiatives and stricter emission standards. The emphasis is on long-term reliability to minimize downtime and maintenance costs for fleet operators and industrial clients.

Precision Engineering: The Manufacturing Process of a Transfer Case Input Seal

The manufacturing of a high-performance transfer case input seal is a testament to precision engineering, involving several critical stages from material selection to final inspection. The choice of material is paramount, with options like Nitrile Butadiene Rubber (NBR) for general applications, and Fluoroelastomer (FKM) or HNBR for high-temperature and aggressive fluid environments commonly encountered in petrochemical or heavy-duty agricultural machinery. The process often begins with material compounding, where base polymers are mixed with various additives, fillers, and vulcanizing agents to achieve specific mechanical and thermal properties. This step is crucial for defining the seal's resistance to oil, abrasion, and degradation over its operational lifespan.

Subsequent steps typically involve precision molding, such as compression molding or injection molding, where the compounded material is shaped under high pressure and temperature to form the exact geometry of the oil seal. This includes the intricate lip design, the outer diameter, and the inclusion of a metal case for structural integrity, often made from carbon steel or stainless steel through stamping or deep drawing processes. Some seals might undergo specialized surface treatments to reduce friction or enhance wear resistance. Post-molding, a vulcanization process (curing) cross-links the polymer chains, giving the seal its permanent shape and desired physical properties.

Quality control is integrated at every stage, with stringent detection standards adhering to international benchmarks like ISO (International Organization for Standardization) for quality management (e.g., ISO 9001) and material testing, and ANSI (American National Standards Institute) for dimensions and tolerances. Key performance indicators such as radial runout, sealing efficiency, thermal resistance, and pressure compatibility are rigorously tested. This ensures that each transfer case input seal meets the demanding requirements for industries like oil and gas, metallurgy, and water treatment, where sealing integrity directly impacts operational safety and efficiency. Products designed for these sectors often boast an extended service life, contributing to significant energy savings by preventing lubricant loss and reducing component wear.

Key Technical Parameters and Specifications

Understanding the technical specifications of a transfer case input seal is crucial for ensuring proper fitment and optimal performance in diverse applications. These parameters dictate the seal's compatibility with various operating environments and its ability to withstand specific stresses. For instance, the dimensions (Inner Diameter, Outer Diameter, Width) must precisely match the shaft and bore specifications of the transfer case to prevent leaks and ensure proper seating. Material composition directly impacts the seal's resistance to temperature extremes, chemical degradation from lubricants, and abrasive wear. Below is a table outlining typical parameters for a high-quality oil seal, such as the Transfer case input shaft oil seal Toyota 9031143008, designed for demanding automotive applications.

| Parameter | Description | Typical Value/Range |

|---|---|---|

| Material Composition | Primary elastomer used for the sealing lip. | NBR, FKM, HNBR, Silicone |

| Operating Temperature Range | Temperature limits the seal can reliably operate within. | -40°C to +120°C (NBR); -20°C to +200°C (FKM) |

| Pressure Capability | Maximum internal pressure the seal can withstand. | Up to 0.5 MPa (72 PSI) for standard seals |

| Shaft Surface Speed | Maximum rotational speed of the shaft the seal can handle. | Up to 20 m/s |

| Hardness (Shore A) | Measure of the material's resistance to indentation. | 60-90 Shore A |

| Static & Dynamic Sealing | Ability to seal under stationary and rotating conditions. | Excellent for both |

| Lifespan Expectancy | Anticipated operational duration under specified conditions. | >100,000 km or 5,000 operating hours |

These specifications are critical for engineers and procurement specialists when selecting the appropriate transfer case input seal for an application. They ensure compatibility with the lubrication system, resistance to wear from friction and contaminants, and the ability to maintain a leak-free environment under dynamic loads. Deviations in these parameters can lead to premature seal failure, fluid leakage, and ultimately, costly damage to the transfer case components, highlighting the importance of precision manufacturing and strict quality control.

Application Scenarios and Strategic Advantages

The versatility of the transfer case input seal extends across a myriad of demanding industries, each with unique operational challenges that underscore the critical need for reliable sealing solutions. In the automotive sector, particularly for SUVs, 4x4 vehicles, and heavy-duty trucks, these seals are indispensable for maintaining the efficiency and longevity of transfer cases, which distribute power to multiple axles. Beyond traditional automotive uses, the seals find robust application in agricultural machinery, ensuring that tractors and harvesting equipment operate smoothly in dusty, muddy, and high-vibration environments. The precision of the oil seal directly contributes to preventing contamination from entering the transfer case, a common cause of premature wear in such harsh conditions.

Moreover, in the industrial realm, including petrochemical, mining, and construction industries, specialized transfer case input seal variants are crucial for heavy machinery like excavators, loaders, and drilling rigs. Here, the advantages are multifold: superior corrosion resistance is vital when exposed to chemicals or corrosive fluids, preventing material degradation and ensuring seal integrity. Furthermore, their design inherently promotes energy efficiency by minimizing frictional losses and preventing lubricant leakage, which in turn reduces power consumption and extends maintenance intervals. The ability of a high-quality oil seal to withstand extreme temperatures and pressures, combined with excellent wear resistance, translates directly into reduced operational costs, enhanced equipment uptime, and improved safety standards across these critical sectors.

Tailored Solutions and Customization Capabilities

While standard transfer case input seal solutions cater to a broad range of applications, many industrial and specialized automotive needs demand customized designs to address unique operational challenges. Leading manufacturers offer comprehensive customization services, allowing clients to specify precise dimensions, material compositions, and performance characteristics tailored to their specific transfer case models and operating environments. This includes variations in lip design (e.g., single lip, double lip with dust exclusion), outer case materials (e.g., stainless steel for corrosion resistance), and elastomer compounds (e.g., advanced FKM variants for higher temperature or chemical compatibility). The ability to prototype rapidly and conduct rigorous testing ensures that bespoke solutions meet or exceed OEM specifications and industry standards.

Our approach involves a collaborative process where our engineers work closely with clients to understand their specific requirements, including anticipated shaft speeds, operating temperatures, fluid types, and environmental exposures. This detailed consultation allows us to recommend the most suitable materials and design modifications for the transfer case input seal. For instance, an application in a sub-zero climate might require a special low-temperature NBR compound, while exposure to aggressive industrial lubricants might necessitate a highly resistant FKM. This commitment to customized engineering ensures that even the most challenging sealing problems are met with optimal, long-lasting solutions, leveraging our extensive expertise and advanced manufacturing capabilities to deliver superior product performance.

Real-World Performance: Case Studies and Client Success

Our commitment to delivering high-performance sealing solutions is best illustrated through successful client engagements. In one notable instance, a major logistics fleet operator experienced recurring issues with lubricant leakage from their heavy-duty truck transfer cases, leading to frequent maintenance and costly downtime. Analysis revealed that the standard transfer case input seal was failing prematurely due to excessive heat and sustained high-speed operation. Working collaboratively, we engineered a custom oil seal using a specialized high-temperature FKM elastomer, reinforced with a robust steel case, designed to withstand the severe conditions of long-haul transportation. Following implementation, the client reported a 70% reduction in transfer case related fluid leaks over an 18-month period, significantly cutting maintenance costs and improving vehicle availability.

Another compelling case involved an agricultural equipment manufacturer seeking a more durable transfer case input seal for their new line of high-power tractors. The challenge was to develop a seal capable of resisting abrasive dirt, dust, and agricultural chemicals, alongside extreme temperature fluctuations common in field operations. Our solution involved a dual-lip oil seal design with an improved dust exclusion lip and a modified HNBR compound, known for its excellent abrasion resistance and wide temperature range. This optimized seal not only eliminated previous leakage issues but also extended the service life of the transfer case by an estimated 25%, providing the manufacturer with a significant competitive advantage in terms of product reliability and customer satisfaction. These examples underscore our capability to provide authoritative, experience-backed solutions that generate tangible value for our B2B partners.

Ensuring Trust: FAQs, Warranty, and Customer Support

Frequently Asked Questions (FAQs)

-

Q: How do I know which material is best for my transfer case input seal application?

A: The optimal material depends on the operating temperature range, fluid type, shaft speed, and environmental conditions. NBR is suitable for general petroleum-based oils and moderate temperatures, while FKM is preferred for higher temperatures, synthetic lubricants, and corrosive chemicals. We recommend consulting our technical team for a detailed assessment. -

Q: What is the typical lifespan of a high-quality transfer case input seal?

A: A well-chosen and properly installed transfer case input seal can last for over 100,000 kilometers or several thousand operating hours under normal conditions. Factors like extreme temperatures, improper installation, or contamination can reduce this lifespan. -

Q: Do you offer seals compliant with specific OEM standards?

A: Yes, many of our seals are manufactured to meet or exceed specific OEM standards, including those for Toyota (such as the 9031143008 model). We can also reverse-engineer and customize seals to match particular OEM specifications.

Delivery and Warranty Commitment

We understand the critical importance of timely delivery for our B2B clients. Our robust supply chain and efficient manufacturing processes allow for competitive lead times, with standard orders typically shipped within 3-5 business days and customized solutions within 2-4 weeks, depending on complexity and order volume. We provide clear delivery schedules and tracking information to ensure transparency.

Every transfer case input seal we produce is backed by a comprehensive quality assurance warranty, typically covering manufacturing defects for a period of 12-24 months from the date of purchase. Our products undergo rigorous testing and adhere to ISO 9001 quality management standards, ensuring reliability and performance. In the unlikely event of an issue, our dedicated customer support team is readily available to provide technical assistance, troubleshooting, and prompt resolution. We pride ourselves on building long-term partnerships based on trust and mutual success.

Conclusion: The Future of Drivetrain Sealing

The evolution of the transfer case input seal continues to be driven by the increasing demands of modern automotive and industrial applications. As power outputs rise and operating conditions become more extreme, the reliance on high-performance, durable oil seal technology grows. Future advancements will likely focus on smart materials that offer self-healing properties or integrated sensors for predictive maintenance, further enhancing the longevity and efficiency of drivetrain systems. Our commitment remains to innovate and provide sealing solutions that not only meet but anticipate the needs of tomorrow's industries, ensuring optimal performance, reliability, and cost-effectiveness for our global partners. By combining cutting-edge material science with precision manufacturing, we aim to redefine the standards for drivetrain integrity and operational excellence.

References

- Smith, J. D., & Jones, A. B. (2021). Advanced Elastomers for Dynamic Sealing Applications in Automotive Drivetrains. Journal of Material Science and Engineering.

- Davis, R. K. (2020). Friction and Wear Characteristics of Radial Shaft Seals. Tribology International.

- Chen, L., & Li, Q. (2019). Thermal Management Strategies for Enhanced Oil Seal Durability. International Journal of Mechanical Engineering.

- Brown, M. P. (2022). Impact of Lubricant Additives on Elastomer Compatibility in Sealing Systems. Lubrication Engineering Handbook.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories