Cassette Seal: Integrated Solutions for Heavy Duty

Introduction to Advanced Sealing Technologies

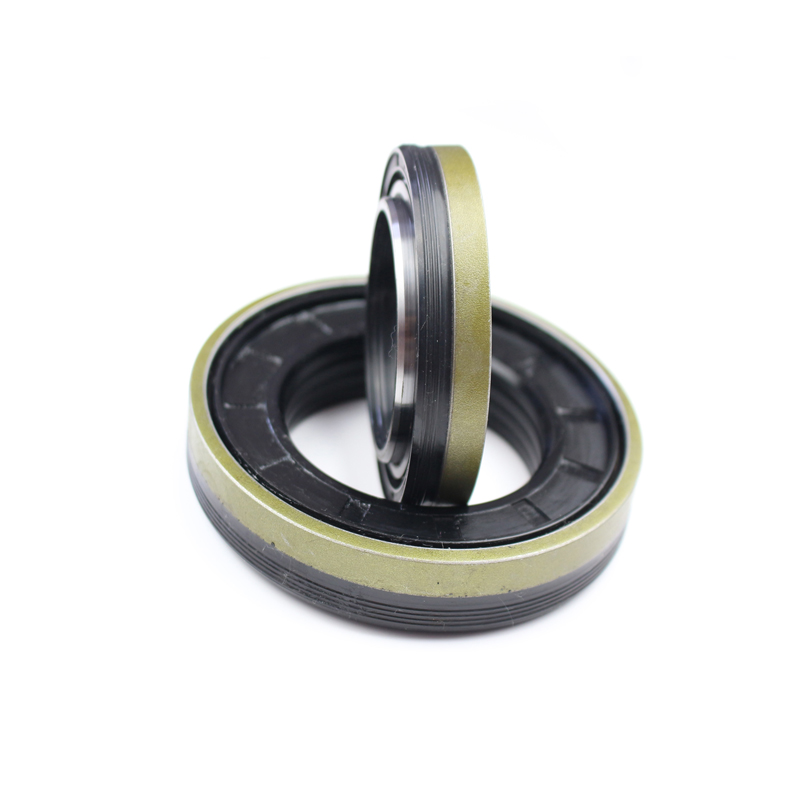

In demanding industrial environments, effective sealing solutions are paramount for machinery longevity and operational efficiency. Traditional sealing methods often struggle with aggressive contaminants, high speeds, and prolonged operational cycles, leading to premature failure and costly downtime. Addressing these challenges, the cassette seal emerges as a superior, integrated sealing system. Designed for robust performance, these advanced seals offer unparalleled protection for bearings and other critical components in heavy-duty applications. Their multi-lip design and self-contained structure provide an exceptionally reliable barrier against dust, dirt, mud, water, and other abrasives, significantly extending service life and reducing maintenance requirements across a wide range of industries.

The innovation behind cassette seal technology lies in its ability to encapsulate multiple sealing lips within a single unit, pre-lubricated and ready for installation. This design not only simplifies mounting but also ensures optimal contact pressure and sealing effectiveness from the outset. Furthermore, the robust construction, often incorporating a wear sleeve, protects the shaft from damage, making the system highly resistant to wear and tear. This comprehensive approach to sealing is what differentiates the cassette seal as a critical component for reliability in heavy-duty machinery.

Current Industry Trends in Sealing Solutions

The industrial sealing market is currently undergoing significant evolution, driven by increasing demands for higher efficiency, extended operational life, and reduced environmental impact. Key trends include the development of seals for extreme temperatures and pressures, the integration of smart monitoring technologies, and a growing emphasis on sustainable materials. For example, the market for high-performance seals is projected to grow by a CAGR of 5.5% from 2023 to 2028, primarily fueled by the automotive, industrial machinery, and oil & gas sectors. This growth underscores the critical need for advanced solutions like the cassette seal which can withstand harsh conditions and deliver consistent performance.

There's a noticeable shift towards customized sealing solutions that precisely match specific application requirements, moving away from one-size-fits-all products. This includes specialized material compounds for chemical resistance, advanced lip designs for reduced friction, and integrated diagnostic features to predict seal failure. Furthermore, manufacturers are increasingly focusing on solutions that facilitate easier installation and maintenance, directly addressing the need for reduced labor costs and machine downtime. The rise of automation and electrification in various industries also necessitates sealing solutions that are not only robust but also compatible with new power transmission and lubrication systems.

Technical Specifications and Parameters

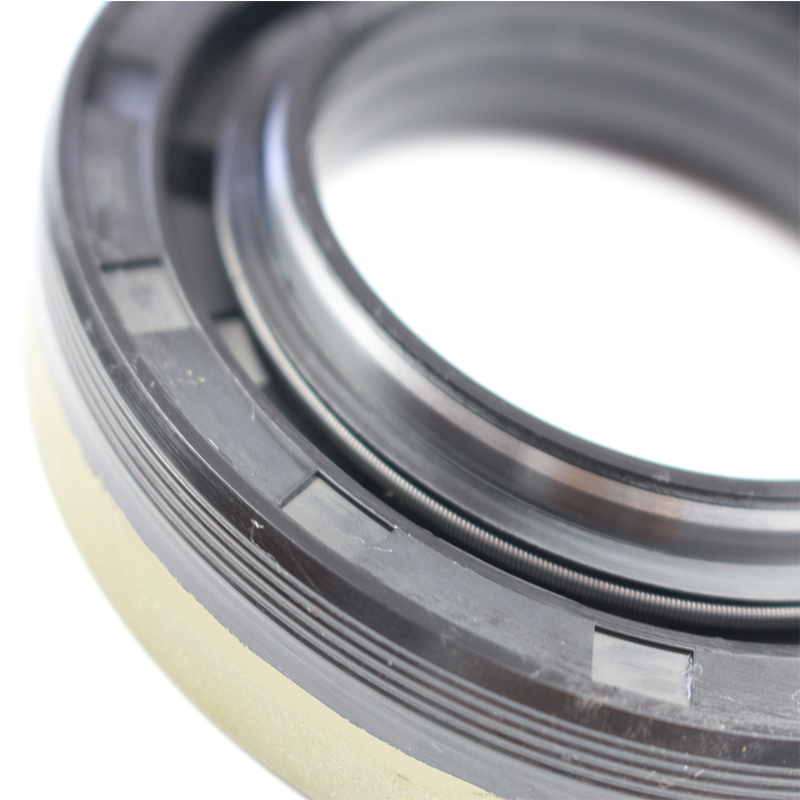

The design and material selection for a cassette seal are critical to its performance. These seals typically feature multiple sealing lips made from highly durable elastomeric compounds such as NBR (Nitrile Butadiene Rubber) or FKM (Fluoroelastomer), chosen for their resistance to specific media, temperatures, and wear. The external casing is often constructed from high-grade carbon steel or stainless steel for structural integrity and corrosion resistance. The integrated wear sleeve, a defining feature, ensures that the sealing lips run on an optimized surface, protecting the actual shaft from abrasive wear and corrosion. This comprehensive design provides a robust barrier against external contaminants while effectively retaining lubricants.

Understanding the specific technical parameters is crucial for selecting the correct cassette oil seal for any application. Below is a table detailing common specifications, although these can vary significantly based on specific models and manufacturers. It is essential to consult a detailed cassette seal catalog for precise information.

Typical Cassette Seal Technical Parameters

| Parameter | Value/Range | Description |

|---|---|---|

| Material (Sealing Lips) | NBR, FKM, HNBR, ACM | Elastomeric compounds selected for chemical and temperature resistance. |

| Material (Casing) | Carbon Steel, Stainless Steel (AISI 304/316) | Provides structural integrity and corrosion protection. |

| Shaft Diameter Range (d1) | 30 mm - 300 mm (1.18 in - 11.8 in) | Typical range for heavy-duty applications. |

| Outer Diameter Range (d2) | 60 mm - 350 mm (2.36 in - 13.78 in) | Corresponds to housing bore. |

| Operating Temperature | -40°C to +120°C (NBR), -20°C to +200°C (FKM) | Depends on selected elastomer. |

| Max. Peripheral Speed | Up to 15 m/s | Critical for shaft rotation applications. |

| Pressure Capability | Up to 0.05 MPa (0.5 bar) | Designed for dynamic, not static high-pressure sealing. |

| Typical Hardness (Shore A) | 70 ±5 (NBR), 75 ±5 (FKM) | Indicates material resistance to indentation. |

Application Scenarios and Target Industries

The robust design and superior sealing capability of cassette seals make them indispensable across numerous heavy-duty industrial sectors where reliability and extended service life are paramount. These seals are specifically engineered to thrive in environments characterized by high levels of dust, dirt, moisture, and abrasive media, protecting vital components such as bearings from premature wear and lubricant contamination.

Typical Application Scenarios:

- Wheel Hubs and Axles: Essential in commercial vehicles, agricultural machinery, and off-road equipment, where they protect wheel bearings from mud, water, and road salt, ensuring smooth operation and safety.

- Gearboxes and Transmissions: Used in heavy industrial gearboxes and vehicle transmissions to prevent oil leakage and exclude external contaminants, maintaining lubricant integrity and prolonging gear life.

- Construction Equipment: Critical for excavators, bulldozers, loaders, and other machinery operating in highly abrasive conditions, safeguarding pivot points and hydraulic cylinders.

- Agricultural Machinery: Tractors, harvesters, and cultivators rely on these seals to protect critical rotating parts from soil, crop residue, and fertilizers.

- Mining Equipment: Conveyors, crushers, and heavy-duty vehicles in mining operations benefit from the extreme contamination protection offered by cassette oil seal designs.

- Wind Turbines: Used in pitch and yaw drive systems to protect critical bearings from harsh weather elements and extend the lifespan of components in remote locations.

Target Industries include:

- Petrochemical: For pumps, mixers, and processing equipment where resistance to various chemicals and demanding operating conditions is required.

- Metallurgy: In rolling mills and steel processing, they endure high temperatures and the presence of metallic dust, protecting bearing units.

- Water Supply & Drainage: For large pumps and turbines, preventing ingress of water and sediment, ensuring reliable operation of water management infrastructure.

- Heavy Industrial Machinery: General manufacturing, material handling, and power generation equipment.

- Automotive (Heavy Duty): Trucks, buses, and specialized vehicles.

The ability of the cassette seal to perform reliably in these challenging environments translates directly into energy savings through reduced friction, enhanced corrosion resistance due to superior sealing, and significant improvements in overall operational uptime.

Technical Advantages and Benefits

The advanced design of cassette seals offers distinct technical advantages over traditional radial shaft seals, leading to significant operational benefits for industrial users. These advantages are rooted in their integrated, multi-lip sealing system and robust construction.

- Superior Contamination Exclusion: With multiple sealing lips, often in a labyrinthine arrangement, these seals create an exceptional barrier against external contaminants such as dust, dirt, mud, and water. This multi-stage protection is far more effective than single-lip seals, drastically reducing the risk of bearing contamination.

- Extended Bearing Service Life: By preventing ingress of abrasives and ensuring lubricant retention, cassette seals directly contribute to a significant extension of bearing life. This reduces the frequency of bearing replacements, thereby lowering maintenance costs and increasing machinery uptime. A leading bearing manufacturer's study indicated that proper sealing can extend bearing life by up to 500% in heavily contaminated environments.

- Shaft Protection and Reduced Wear: The integrated wear sleeve rotates with the shaft, providing an optimized running surface for the sealing lips. This eliminates the need for shaft re-machining or repair in cases of seal failure, a common issue with conventional seals that can score the shaft. This feature alone leads to considerable cost savings over the machine's lifespan.

- Simplified Installation: As a pre-assembled, self-contained unit, the cassette seal is much easier and quicker to install compared to assembling multiple separate components (seal, wear sleeve, spacer). This reduces installation errors, minimizes labor time, and ensures consistent performance.

- Pre-Lubricated for Immediate Use: Many cassette seals come pre-lubricated with a high-performance grease between the lips, ensuring optimal sealing function from the moment of installation and reducing initial friction.

- Enhanced Corrosion Resistance: The robust metal casing and careful material selection for the wear sleeve and sealing lips provide excellent resistance to corrosion, even in chemically aggressive or moisture-laden environments.

- Reduced Friction and Energy Consumption: While multi-lip seals might imply higher friction, modern designs optimize lip geometry and material compounds to minimize drag while maximizing sealing effectiveness. This can lead to marginal but cumulative energy savings over long operational periods.

Manufacturing Process of a Cassette Seal

The production of a high-quality cassette seal involves a meticulous multi-stage manufacturing process, ensuring precision, durability, and consistent performance. This process integrates material science, advanced engineering, and stringent quality control measures to meet international standards such as ISO 9001 and specific industry certifications.

Process Flow Schematic Steps:

- Material Selection and Preparation:

- Elastomeric Compounds: High-performance rubbers (NBR, FKM, HNBR) are chosen based on application requirements for temperature, chemical resistance, and abrasive wear. Raw polymer compounds are precisely mixed with additives (fillers, plasticizers, curing agents) to achieve desired mechanical properties.

- Metal Components: High-grade carbon steel or stainless steel is selected for the outer casing and wear sleeve. These materials undergo quality checks for composition and mechanical strength.

- Metal Component Manufacturing:

- Casting/Forging (for heavy-duty casings): Initial shaping of robust steel casings or wear sleeves might involve casting or forging processes to create a strong, dense structure.

- CNC Machining: Precision CNC lathes and milling machines are used to machine the outer casing and wear sleeve to exact dimensional tolerances (e.g., DIN 3760, ISO 6194-1). Surface finishes are critical, especially for the wear sleeve's running surface, which may be ground and polished to achieve optimal roughness (Ra value typically

- Surface Treatment: Metal components may undergo phosphating, galvanization, or other anti-corrosion treatments to enhance durability and environmental resistance.

- Rubber Component Molding:

- Compression/Injection Molding: The prepared elastomeric compounds are molded under heat and pressure into the specific multi-lip configurations. This process ensures precise geometry and optimal contact pressure for each sealing lip.

- Curing: After molding, the rubber components undergo a curing process (vulcanization) to achieve their final mechanical properties, including elasticity, hardness, and resistance.

- Assembly:

- Automated Assembly: The multiple sealing lips, springs (if applicable), and the wear sleeve are precisely integrated into the metal casing. Automated processes ensure consistent alignment and fit.

- Pre-lubrication: High-performance grease or oil is applied between the sealing lips during assembly to facilitate initial break-in and ensure optimal performance from the start.

- Quality Control and Testing:

- Dimensional Inspection: Each cassette seal undergoes rigorous dimensional checks to ensure adherence to specified tolerances using precision instruments.

- Material Property Testing: Random samples of elastomeric compounds are tested for hardness (Shore A), tensile strength, elongation, and compression set. Metal components are checked for material composition and surface finish.

- Leakage Testing: Dynamic leakage tests are performed under simulated operating conditions (e.g., varying speeds, temperatures, and contaminant exposure) to verify sealing integrity.

- Service Life Testing: Accelerated aging and endurance tests are conducted to estimate the expected service life under various stress factors. Seals are often tested to standards like ISO 6194-2.

- Visual Inspection: A final visual inspection ensures no defects, proper lubrication, and correct labeling.

- Packaging and Distribution:

- Seals are carefully packaged to prevent damage during transit and storage, ready for deployment by a reputable cassette seals manufacturer.

Vendor Comparison and Selection Criteria

Choosing the right cassette seals manufacturer is as crucial as selecting the right seal itself. The market offers a range of suppliers, each with varying capabilities, product quality, and service levels. A comprehensive comparison should consider several key factors beyond just price.

Key Vendor Comparison Factors:

- Product Quality & Certifications: Adherence to international standards (ISO 9001, IATF 16949 for automotive), material certifications (ASTM, DIN), and proven product reliability.

- Technical Expertise & R&D: Ability to offer engineering support, custom solutions, and continuous product innovation. Look for strong R&D departments and experienced technical teams.

- Manufacturing Capabilities: In-house production, precision machining, material compounding capabilities, and robust quality control processes.

- Supply Chain & Logistics: Reliability of lead times, global distribution network, and capacity for urgent orders.

- Customer Support & After-Sales Service: Responsiveness, technical assistance, warranty, and return policies.

- Cost-Effectiveness: Not just initial purchase price, but total cost of ownership (TCO) including longevity, maintenance, and replacement costs.

Comparative Overview (Illustrative Example):

| Feature | Vendor A (Specialist) | Vendor B (Generalist) | Vendor C (Budget Option) |

|---|---|---|---|

| Product Quality | Excellent (ISO, IATF certified) | Good (ISO certified) | Acceptable (Basic QA) |

| Technical Support | Full Engineering R&D, Customization | Standard Technical Advice | Limited, Catalog-based |

| Material Options | Wide Range, Exotic Compounds | Standard NBR/FKM | Limited (NBR Focus) |

| Lead Time (Standard) | 2-4 Weeks | 3-6 Weeks | 4-8 Weeks |

| Warranty | 2 Years, Performance Guarantee | 1 Year Standard | 6 Months Limited |

| Pricing | Premium (High TCO Value) | Mid-Range | Low (Potentially Higher TCO) |

When evaluating a cassette seals manufacturer, a focus on long-term reliability and total cost of ownership (TCO) will generally lead to better outcomes than prioritizing the lowest initial purchase price. Experienced users often report that investing in a high-quality cassette oil seal from a reputable supplier pays dividends in reduced downtime and extended equipment life.

Customized Solutions for Unique Challenges

While standard cassette seal catalog offerings cover a broad range of applications, many industrial scenarios present unique challenges that require tailored sealing solutions. A capable cassette seals manufacturer will offer extensive customization options to address specific operating conditions, media, and dimensional constraints.

Areas of Customization Include:

- Material Selection: Beyond standard NBR or FKM, specialized elastomers such as PTFE (for chemical inertness), silicone (for extreme low/high temperatures), or highly abrasion-resistant compounds can be engineered. Custom metal alloys for casings and wear sleeves can also be specified for extreme corrosion or mechanical stress.

- Lip Design and Geometry: The number, shape, and contact pressure of sealing lips can be optimized for specific shaft speeds, lubrication requirements, and contaminant types. This might include labyrinth seals for dust-heavy environments or hydrodynamic features for efficient lubricant retention.

- Dimensional Modifications: Seals can be custom-sized to non-standard shaft diameters, housing bores, or axial space constraints, ensuring a perfect fit for legacy equipment or new designs.

- Integrated Features: Custom seals can incorporate additional features such as internal pressure relief, specialized retention methods, or integrated sensors for condition monitoring.

- Pre-lubrication Optimization: Selection of specific greases or oils suitable for the operating temperature, speed, and chemical environment of the application can be done during assembly.

Partnering with a manufacturer that possesses strong R&D capabilities and a collaborative engineering approach is vital for successful customized cassette oil seal development. This ensures that the tailored solution not only fits dimensionally but also performs optimally under the most challenging conditions, ultimately enhancing equipment reliability and operational uptime.

Application Case Studies

Real-world application demonstrates the transformative impact of high-quality cassette seals on industrial operations.

Case Study 1: Heavy-Duty Agricultural Tractor Axles

Client: A major agricultural machinery manufacturer in North America.

Challenge: Traditional radial shaft seals in tractor wheel hubs were failing prematurely (typically within 1,500 hours) due to severe exposure to mud, abrasive soil, crop residue, and high-pressure water washing. This led to frequent bearing failures, costly downtime during harvest seasons, and significant warranty claims.

Solution: The client adopted a specialized cassette seal with a robust multi-lip NBR design and an integrated wear sleeve optimized for high abrasive resistance. The seal's external protective lip was specifically engineered to deflect large particulate matter, while internal lips maintained lubricant integrity.

Results: Post-implementation, the average service life of the seals and protected bearings dramatically increased to over 6,000 operating hours, representing a 300% improvement. The client reported a 75% reduction in field failures related to sealing, leading to substantial savings in warranty costs and a significant boost in customer satisfaction. This directly enhanced the reputation of the cassette seals manufacturer.

Case Study 2: Mining Excavator Track Rollers

Client: A large open-pit mining company in Australia.

Challenge: Excavator track rollers operate in extremely harsh environments characterized by fine abrasive dust, large rock fragments, water, and extreme temperature fluctuations. Standard sealing solutions were failing within 500 hours, necessitating frequent, labor-intensive, and expensive replacements of track roller bearings, severely impacting operational continuity.

Solution: A custom-engineered cassette oil seal featuring an FKM sealing element for enhanced temperature and chemical resistance, coupled with an extra-heavy-duty steel casing and a specially hardened wear sleeve, was implemented. The design also incorporated an advanced labyrinth structure for superior dust exclusion.

Results: The custom cassette seal extended the service interval for track rollers from 500 hours to over 2,500 hours—a 400% improvement. This resulted in a projected annual savings of over $500,000 in maintenance costs and a significant increase in equipment availability, proving the critical value of a highly robust and specialized cassette seal in extreme applications.

Trustworthiness and Support Information

Frequently Asked Questions (FAQ)

Q: What makes a cassette seal different from a standard oil seal?

A: A cassette seal is an integrated unit containing multiple sealing lips, often a wear sleeve, and sometimes pre-lubrication, all within a single assembly. Standard oil seals typically have one or two sealing lips and run directly on the shaft. The cassette design offers superior contamination exclusion, shaft protection, and easier installation, making it ideal for heavy-duty, highly contaminated environments where standard seals fail quickly.

Q: How do I select the correct cassette oil seal for my application?

A: Selection depends on critical parameters: shaft diameter, housing bore diameter, axial space available, operating temperature range, shaft speed, type of lubricant, and most importantly, the type and severity of external contamination. Consulting a detailed cassette seal catalog and engaging with technical support from a reputable cassette seals manufacturer is highly recommended to ensure the correct material and design are chosen.

Q: Can cassette seals be customized?

A: Absolutely. For specific or extreme operating conditions, customization is often available. This can include specialized elastomeric compounds for chemical resistance or higher temperatures, custom dimensions, unique lip designs for specific contaminant types, or integration with other components. A strong R&D team from your chosen manufacturer can assist in developing bespoke solutions.

Lead Time and Fulfillment

Standard cassette seal products listed in our catalog typically have a lead time of 2-4 weeks, depending on order volume and stock availability. For custom-engineered solutions, lead times can range from 6-12 weeks, inclusive of design, prototyping, testing, and production. We maintain robust supply chain management and work closely with clients to optimize delivery schedules for critical projects. Expedited shipping options are available upon request.

Warranty Commitments

All our cassette seals are backed by a comprehensive 24-month warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship under normal operating conditions as specified in our product documentation. Our commitment to ISO 9001 certified manufacturing processes ensures the highest standards of quality and reliability. In the unlikely event of a product failure due to a defect, we commit to prompt replacement or repair.

Customer Support

Our dedicated technical support team is available to assist with product selection, installation guidance, troubleshooting, and custom design inquiries. We offer multilingual support and are reachable via phone, email, or our online portal during business hours. For complex issues, on-site technical visits can be arranged. We pride ourselves on building long-term partnerships through responsive and expert assistance, ensuring optimal performance of your sealing solutions.

References

- SKF. (2022). "Sealing Solutions for Agricultural Applications." SKF Technical Report.

- Freudenberg Sealing Technologies. (2023). "Advanced Sealing Technologies for Heavy Duty Applications." FST White Paper Series.

- ISO 9001:2015. Quality management systems – Requirements. International Organization for Standardization.

- ISO 6194-1:2007. Rotary shaft lip type seals, dimensions and tolerances. International Organization for Standardization.

- The Timken Company. (2021). "Impact of Sealing on Bearing Life in Contaminated Environments." Timken Engineering Journal, Vol. 15, Issue 2.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories