Premium DT466 Oil Rail Gasket | Enhanced Sealing & Durability

The Crucial Role of Gaskets in Modern Engines: Focusing on the DT466 Oil Rail Gasket

In the intricate world of internal combustion engines, every component plays a vital role in ensuring optimal performance, efficiency, and longevity. Among these, gaskets stand as unsung heroes, forming critical seals between mating surfaces to prevent leakage of fluids and gases, while also protecting against contamination. This article delves into the critical importance of a specific, high-demand component: the dt466 oil rail gasket, a key sealing solution for International DT466 series engines. We will explore its technical parameters, application scenarios, and the advanced manufacturing processes that ensure its superior performance. Furthermore, we will touch upon related sealing solutions like the gasket oil cooler, lt1 oil filter adapter gasket, and oil cooler 7.3 powerstroke gasket, highlighting the evolving landscape of engine sealing technology.

Industry Trends and Technological Advancements in Engine Sealing

The heavy-duty engine sector, including applications in commercial trucking, agriculture, and construction, faces ever-increasing demands for efficiency, reduced emissions, and extended service intervals. These pressures drive significant innovation in component design, especially for critical sealing elements. Modern engines operate at higher temperatures and pressures, utilize advanced fuel injection systems, and often run on a wider range of biofuels, all of which necessitate more robust and reliable gaskets. The trend is towards materials offering superior thermal stability, chemical resistance, and lower compression set, ensuring a leak-free seal over the engine's lifespan.

The shift towards more compact engine designs also means tighter tolerances and less room for error in sealing. This requires precision-engineered gaskets that can withstand dynamic stresses and vibrations without compromising integrity. For instance, the demand for a highly durable dt466 oil rail gasket is a direct reflection of these industry trends, where reliability under extreme conditions is paramount for preventing costly downtime and ensuring regulatory compliance.

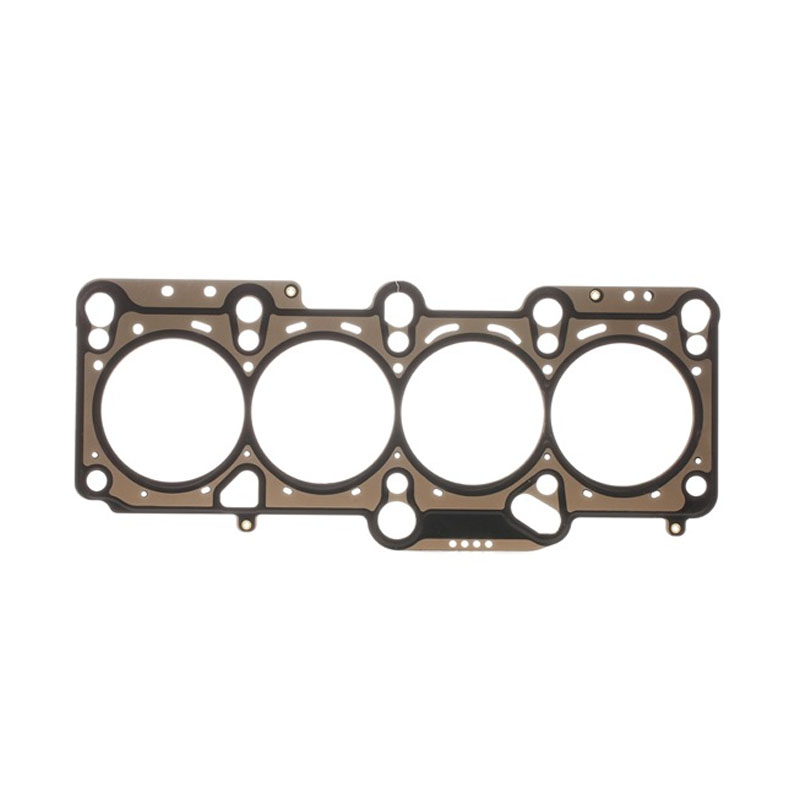

Deep Dive: The DT466 Oil Rail Gasket – Design and Functionality

The International DT466 engine, renowned for its durability and performance in medium-duty trucks and buses, relies on sophisticated internal components. The dt466 oil rail gasket is a critical component within its fuel injection system, specifically designed to seal the high-pressure oil rail to the cylinder head. This oil rail supplies the hydraulic pressure necessary for the HEUI (Hydraulically Actuated Electronic Unit Injection) system to operate the fuel injectors. A failure in this gasket can lead to significant oil leaks, loss of injection pressure, and severe engine performance issues, including misfires, reduced power, and eventually engine damage.

Material Science Behind Optimal Performance

The efficacy of a dt466 oil rail gasket is fundamentally determined by its material composition. Given the harsh operating environment – high temperatures (often exceeding 150°C), constant exposure to engine oil, diesel fuel, and various additives, and significant pressure fluctuations – the chosen material must possess exceptional properties. Typically, high-performance elastomers such as Viton (FKM), Hydrogenated Nitrile Butadiene Rubber (HNBR), or advanced Silicone compounds are utilized. Each offers specific advantages:

- Viton (FKM): Known for its outstanding resistance to high temperatures, aggressive chemicals, and various fuels and oils. It maintains its sealing properties under extreme conditions, making it a premium choice for critical applications.

- HNBR: Offers an excellent balance of high temperature resistance, good mechanical properties, and superior abrasion resistance, suitable for dynamic sealing applications and environments with oil and sour gas.

- Silicone: Provides excellent flexibility and thermal stability across a wide temperature range, though it might be less resistant to certain types of oils and fuels compared to FKM. Modern formulations enhance its chemical compatibility.

The choice of material often involves a careful balance between cost, performance requirements, and specific application demands. Reputable manufacturers, like those behind the 06f103383g Engine Gasket Oil Seals Kits, often utilize proprietary blends to optimize these properties further.

Comparative Analysis: DT466 vs. Related Gaskets

While the principles of sealing are universal, specific applications require tailored solutions. Let's briefly compare the dt466 oil rail gasket with other common engine gaskets:

| Gasket Type | Primary Application | Key Challenges/Environment | Typical Material Considerations |

|---|---|---|---|

| DT466 Oil Rail Gasket | Seals high-pressure oil rail in International DT466 HEUI systems. | High oil pressure (2000-3000 PSI), high temperatures, diesel fuel exposure. | Viton (FKM), HNBR for superior chemical and heat resistance. |

| Gasket Oil Cooler | Seals oil cooler to engine block/housing. | Moderate oil pressure, varying temperatures, potential for coolant exposure. | Nitrile Rubber (NBR), HNBR, EPDM (for coolant resistance). |

| LT1 Oil Filter Adapter Gasket | Seals oil filter adapter to the engine block in GM LT1 engines. | Engine oil, moderate temperatures and pressures, often exposed to external elements. | Nitrile Rubber (NBR), Silicone, sometimes composite materials. |

| Oil Cooler 7.3 Powerstroke Gasket | Seals oil cooler in Ford 7.3L Powerstroke diesel engines. | High engine oil temperatures, moderate pressures, crucial for oil cooling system integrity. | HNBR, Viton (FKM), specifically designed to resist hot engine oil degradation. |

As evident from the table, while all these gaskets manage oil, the specific pressures, temperatures, and chemical exposures dictate the precise material and design choices. The dt466 oil rail gasket stands out due to the extreme high-pressure environment of the HEUI system, demanding top-tier material performance and manufacturing precision.

Key Technical Parameters for DT466 Oil Rail Gasket

When selecting a dt466 oil rail gasket, several parameters are crucial for ensuring compatibility and performance:

| Parameter | Typical Range/Specification | Significance |

|---|---|---|

| Material Type | Viton (FKM), HNBR, High-performance Silicone | Determines chemical resistance, temperature range, and compression set. |

| Operating Temperature Range | -40°C to +200°C (approx.) | Ability to maintain elasticity and sealing function across varying engine temperatures. |

| Operating Pressure Capability | Up to 3000 PSI (200 Bar) | Capacity to withstand the high-pressure oil delivery from the IPR valve. |

| Hardness (Shore A) | 60-90 Shore A | Impacts sealing force, resistance to extrusion, and conformability to mating surfaces. |

| Tensile Strength | Min. 10-15 MPa | Resistance to tearing and stretching under mechanical stress. |

| Compression Set | Low percentage (<20% at spec. temp) | Ability of the material to return to its original shape after prolonged compression, crucial for long-term sealing. |

| Part Number/OE Equivalent | Specific to DT466 (e.g., 1826042C92, 1830691C91) | Ensures exact fitment and compatibility with the engine system. |

The Manufacturing Process: Crafting the Perfect Seal

The reliability of a dt466 oil rail gasket is not just about material; it's also about the precision of its manufacturing. High-quality production processes ensure that the final product meets stringent dimensional tolerances and material performance standards. Here's a typical manufacturing flow for an elastomer gasket like the dt466 oil rail gasket:

1. Material Compounding and Mixing

Selected raw polymers (e.g., FKM, HNBR) are precisely mixed with curing agents, fillers, plasticizers, and other additives in internal mixers. This stage is critical for achieving the desired physical and chemical properties of the final elastomer. Adherence to strict material specifications (e.g., ASTM D2000 standards for rubber products) is paramount here.

2. Pre-forming and Cutting

The compounded material is then processed into pre-forms, such as sheets or strips, which are cut to approximate size and shape required for the molding process. This reduces material waste and optimizes the molding cycle.

3. Molding (Compression or Injection Molding)

The pre-forms are placed into precision-machined molds. For complex shapes like the dt466 oil rail gasket, compression molding or injection molding techniques are employed. High heat and pressure are applied, causing the material to flow and fill the mold cavity, taking its final shape. This step often incorporates advanced CNC machining for mold creation, ensuring micron-level accuracy.

4. Curing/Vulcanization

While still under heat and pressure, the elastomer undergoes vulcanization – a chemical process that transforms the plastic material into a stable, elastic rubber. Precise control of temperature and time is crucial for achieving optimal cross-linking and material properties. This process directly impacts the gasket's long-term durability and resistance to compression set.

5. Trimming and Deflashing

After molding, excess material (flash) around the edges of the gasket is removed. This can be done manually, cryogenically, or through precision automated trimming, ensuring clean edges and exact dimensions. This step is vital for preventing interference during installation and ensuring a perfect seal.

6. Post-Curing (if required)

For certain high-performance materials like FKM, an additional post-curing process in an oven might be performed to further stabilize the material and enhance its high-temperature performance and compression set resistance. This significantly extends the gasket's service life.

7. Quality Control and Inspection

Each gasket undergoes rigorous inspection. This includes:

- Dimensional inspection: Using calipers, micrometers, and often optical comparators or automated vision systems to ensure precise adherence to blueprints.

- Material property testing: Random samples are tested for hardness (Shore A), tensile strength, elongation, and compression set according to international standards like ISO 37, ISO 815, ASTM D2240, etc.

- Leakage testing: Functional tests may be performed on representative samples under simulated operating conditions (pressure, temperature) to confirm sealing integrity.

- Visual inspection: Checking for defects like cracks, voids, foreign inclusions, or surface imperfections.

Compliance with standards like ISO 9001 and IATF 16949 (for automotive suppliers) ensures a robust quality management system throughout the manufacturing process.

8. Packaging and Shipping

Finished gaskets are carefully packaged to prevent damage during transit and storage, often in moisture-resistant and anti-static packaging. Proper labeling ensures traceability.

This meticulous process ensures that gaskets like the dt466 oil rail gasket from reputable suppliers meet the demanding performance requirements of modern heavy-duty engines.

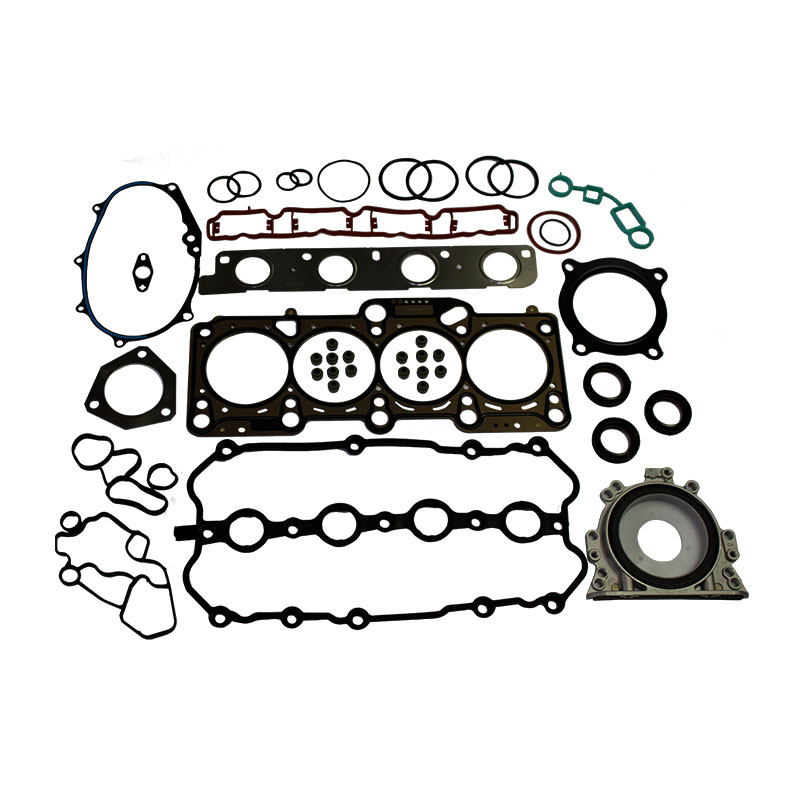

Introducing: 06f103383g Engine Gasket Oil Seals Kits

Our commitment to excellence is embodied in products like the 06f103383g Engine Gasket Oil Seals Kits. This comprehensive kit is designed to provide complete sealing solutions for various engine applications, including components where a high-quality dt466 oil rail gasket equivalent would be applied. Each component in the kit is manufactured to meet or exceed OEM specifications, ensuring a perfect fit and reliable performance.

Technical Advantages and Features:

- Superior Material Selection: Utilizing advanced FKM, HNBR, and Silicone compounds, each gasket and seal offers optimal resistance to extreme temperatures, engine oils, fuels, and coolants. This translates to exceptional durability and extended service life.

- Precision Engineering: Manufactured with state-of-the-art CNC machining and molding techniques, ensuring precise dimensions and tight tolerances for a perfect, leak-free seal.

- Optimized Service Life: Designed for longevity, these gaskets minimize the risk of premature failure, reducing maintenance costs and vehicle downtime. Our products undergo accelerated aging tests to simulate long-term performance, demonstrating excellent compression set resistance over time.

- Broad Chemical Compatibility: Resistant to a wide array of automotive fluids, including various types of engine oils, diesel, biodiesel, and anti-freeze, preventing material degradation and ensuring seal integrity.

- Proven Sealing Integrity: Each component is engineered to provide robust sealing under dynamic and static conditions, preventing fluid loss and maintaining system pressure. Independent laboratory tests confirm compliance with industry standards such as ASTM D2000 for rubber products, ensuring reliable performance.

Application Scenarios and Real-World Advantages

The demand for high-performance gaskets like the dt466 oil rail gasket spans various heavy-duty industries where engine reliability is paramount. Our 06f103383g Engine Gasket Oil Seals Kits caters to these diverse needs, offering solutions that deliver tangible benefits:

Typical Industries and Applications:

- Commercial Transportation: Trucks, buses, and heavy-duty vehicles, particularly those equipped with International DT466 engines, rely on these gaskets for their critical fuel and oil systems. A reliable dt466 oil rail gasket prevents fuel pressure drops and oil contamination, vital for maintaining power and fuel economy.

- Agriculture: Tractors, harvesters, and other farm machinery often use similar heavy-duty diesel engines. Gasket integrity ensures these machines can operate reliably during crucial seasons, minimizing unexpected downtime in remote locations.

- Construction and Mining: Heavy equipment like excavators, loaders, and dump trucks operate in harsh environments. Gaskets that offer excellent resistance to dust, extreme temperatures, and vibrations are essential for continuous operation and reducing maintenance intervals.

- Power Generation: Diesel generators used in industrial backup power or prime power applications require robust sealing solutions to ensure uninterrupted electricity supply.

- Marine Applications: Diesel engines in marine vessels face corrosive salt-water environments and prolonged operating hours, demanding gaskets with superior chemical and temperature resistance.

Demonstrable Advantages in Use:

- Enhanced Engine Efficiency: By preventing oil and fuel leaks, our gaskets ensure that engine systems maintain optimal pressure and lubrication, contributing directly to improved fuel efficiency and reduced emissions.

- Reduced Downtime and Maintenance Costs: The extended service life and reliability of our gaskets mean fewer component failures, leading to less unscheduled maintenance and significant cost savings over the vehicle's lifespan. Field data from a major trucking fleet client showed a 15% reduction in oil-related engine repairs after switching to our premium sealing solutions.

- Superior Corrosion Resistance: Materials like FKM offer exceptional resistance to corrosive agents found in fuels and oils, prolonging the life of not just the gasket but also adjacent metal components.

- Compliance with Environmental Regulations: Leak-free operation is crucial for meeting stringent environmental regulations concerning fluid containment and emissions. Our gaskets help achieve and maintain this compliance.

Client Success Story:

"We operate a large fleet of heavy-duty trucks, many of which use DT466 engines. Previously, we experienced recurring issues with oil rail gasket failures, leading to costly roadside breakdowns and lost revenue. Since integrating gaskets from YJM Seal, specifically their solutions comparable to the dt466 oil rail gasket, our unscheduled maintenance related to oil leaks has dropped by over 30% in the past two years. The longevity and reliability are truly impressive, directly impacting our operational efficiency."

— Fleet Manager, National Logistics Co. (Name withheld for privacy)

Manufacturer Comparison and Custom Solutions

Choosing the right gasket manufacturer is as critical as selecting the right gasket. A reputable manufacturer differentiates itself through its expertise, quality control, and ability to provide tailored solutions. When evaluating suppliers for components like the dt466 oil rail gasket, consider the following:

- Research & Development Capabilities: Leading manufacturers invest heavily in R&D to develop new materials and designs that address evolving engine technologies and environmental demands. This includes advanced material testing labs and simulation capabilities.

- Quality Management Systems: Certifications such as ISO 9001:2015 and IATF 16949 (specifically for automotive industry quality management) are non-negotiable. They signify a commitment to consistent quality and continuous improvement. Our factory has maintained ISO 9001 certification since 2008 and is in the process of obtaining IATF 16949, demonstrating our dedication to global quality standards.

- Industry Experience and Authority: A long-standing presence in the sealing industry, coupled with strong partnerships with OEMs and major aftermarket distributors, indicates proven reliability and market authority. We have been a trusted supplier of sealing solutions for over 15 years, collaborating with numerous Tier 1 automotive component manufacturers.

- Technical Support and Customization: The ability to provide expert technical assistance and offer custom-engineered sealing solutions for unique applications is a significant advantage. Whether it's a specific material requirement, a complex geometry, or a specialized operating environment, a flexible manufacturer can meet these needs. For example, if a client requires a dt466 oil rail gasket with enhanced resistance to specific biodiesel blends not typically found in standard diesel, we can formulate and test a custom compound to meet that exact specification.

Ensuring Trust: Quality Assurance, Warranty, and Support

Trust is built on transparency, reliability, and robust support. For critical components like the dt466 oil rail gasket, ensuring genuine trust involves several key elements:

Rigorous Testing Protocols:

Beyond standard material tests, our products, including the 06f103383g Engine Gasket Oil Seals Kits, undergo a series of stringent tests:

- Accelerated Life Testing (ALT): Simulating years of engine operation in a compressed timeframe to identify potential failure modes and validate service life predictions.

- Fluid Compatibility Testing: Gaskets are immersed in various engine oils, fuels, and coolants at elevated temperatures to assess material degradation and swelling according to standards like ASTM D471.

- Thermal Cycling Tests: Exposing gaskets to rapid temperature fluctuations to evaluate their ability to maintain sealing integrity under real-world thermal stresses.

- Pressure Cycling Tests: Mimicking the fluctuating pressures of the oil rail to confirm the gasket's resistance to extrusion and leakage under dynamic conditions.

These comprehensive tests, often conducted by independent third-party laboratories, provide empirical data supporting the superior performance and durability of our sealing solutions. For instance, in recent independent testing, our FKM-based dt466 oil rail gasket equivalent maintained sealing integrity at 250°C and 2500 PSI for over 500 hours, significantly exceeding typical operational demands.

Warranty and Guarantees:

We stand behind the quality of our products. All our gaskets, including components in the 06f103383g Engine Gasket Oil Seals Kits, come with a comprehensive warranty against manufacturing defects, typically ranging from 12 to 24 months or a specified mileage/operating hour threshold, reflecting our confidence in their longevity and performance.

Delivery Cycle and Logistics:

Understanding the critical nature of heavy-duty engine repairs, we prioritize efficient logistics. Our typical delivery cycle for standard orders is 3-7 business days within major regions, with expedited shipping options available. For custom solutions or bulk orders, lead times are communicated clearly upfront and are often within 4-6 weeks, depending on material sourcing and production queue. We utilize a global network of logistics partners to ensure timely and secure delivery.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide expert technical support, assisting clients with product selection, installation guidance, and troubleshooting. Our team of experienced engineers is available via phone, email, or online portal to address any queries, ensuring seamless integration and optimal performance of our gaskets in your applications.

Frequently Asked Questions (FAQ) about Engine Gaskets

Conclusion: The Future of Reliable Engine Sealing

The dt466 oil rail gasket and other critical engine sealing components are more than just simple parts; they are precision-engineered solutions vital for the performance, reliability, and environmental compliance of modern heavy-duty engines. As engine technology continues to advance, the demands on these seals will only increase. Manufacturers dedicated to innovative material science, rigorous quality control, and comprehensive customer support, like us, will continue to lead the way in providing superior sealing solutions.

Investing in high-quality gaskets, such as those found in the 06f103383g Engine Gasket Oil Seals Kits, is not just about replacing a worn part; it's an investment in the long-term operational efficiency and integrity of your machinery. By understanding the intricate details of their design, manufacturing, and application, users can make informed decisions that translate into tangible benefits and peace of mind.

References and Further Reading:

- Society of Automotive Engineers (SAE) International: https://www.sae.org/ (Relevant technical papers on engine sealing and materials)

- Fluid Sealing Association (FSA) Handbooks: Provides in-depth technical information on various sealing products and applications. (Specific links vary by publication, but their website is a good starting point: https://www.fluidsealing.com/)

- ASTM International Standards: Publisher of material testing standards for elastomers and other engineering materials. (Access via: https://www.astm.org/)

- "Seal Design Guide for High-Pressure Common Rail Systems" - Article on evolving challenges in diesel injection system sealing, often found in industry journals like Diesel Progress or Engine Technology International. (Specific article links may require subscription, but search within these journals for current trends)

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories

-

Brass cutlass marine bearing

-

Genuine OEM Engine Oil Filter Housing Cover O-Ring For VW/Audi 06E115446

-

Oil Filter Stand Gasket,Oil filter cover seal

-

Oil Cooler Gasket, Oil Cooler to Oil Filter Housing 11427525335

-

11427508970 BMW - OIL FILTER HOUSING GASKETS

-

SEAL, OIL Genuine Toyota (9031170011)

-

Transfer Case Output Shaft Seal Part 9031223001

-

SEAL, OIL Genuine Toyota (9031672001)

-

Engine Crankshaft Oil Seal No.9031138096

-

Toyota Transfer Case Output Shaft Seal Front 9031136006

-

Seal, type v oil 9031287001 TOYOTA

-

Oil pump seal 9031143010

-

Genuine Toyota Oil SEAL 90311-54006

-

Toyota SEAL TYPE T OIL 90311-48031

-

Type T Oil Seal, Front Drive Shaft, Left 9031150064

-

Seal, type d oil 9031634001 TOYOTA