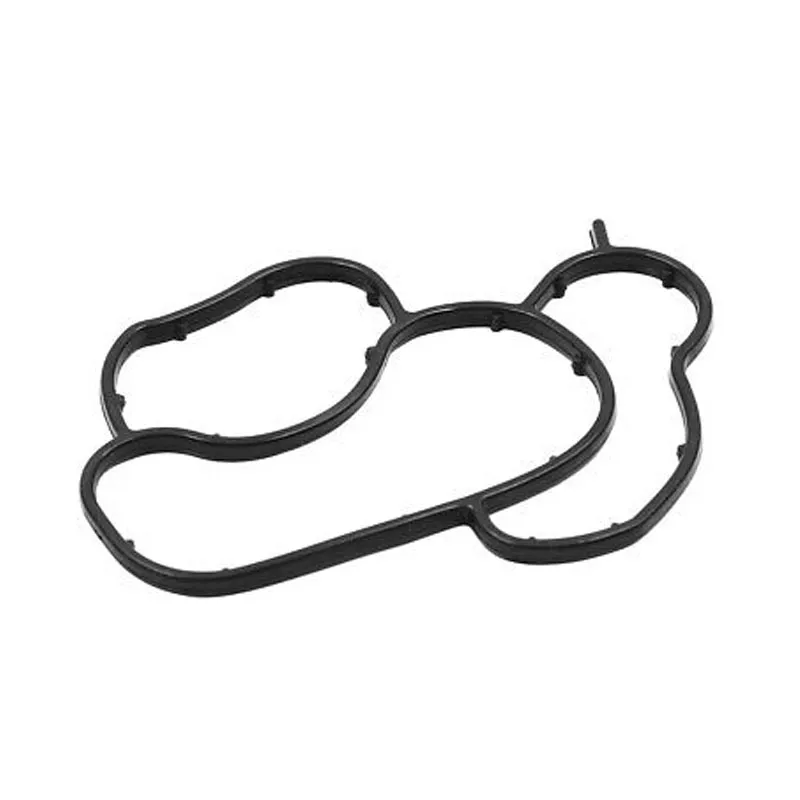

flange oil seal

Authoritativeness on the subject is demonstrated when one can critically examine both innovative and traditional sealing technologies. Seals with auxiliary lip designs, for example, provide enhanced dust and dirt protection. Meanwhile, the use of labyrinth designs in some flange oil seal applications offers exceptional friction reduction and improved life span, although typically at a higher cost. Trustworthiness in this domain is built through transparency and accountability. Reliability tests and certifications from recognized bodies play a key role in verifying product claims. Genuine manufacturers provide detailed data sheets and operational guides which ensure that their seals meet specific industrial standards. Moreover, I advise the importance of training maintenance personnel on proper installation techniques, as even the most premium seals can underperform if improperly fitted. Ultimately, the use of flange oil seals is a testament to engineering’s capacity to extend equipment life and maintain operational efficiency. For businesses, selecting the appropriate flange oil seal can mean the difference between seamless operation and costly repairs. By marrying experience with detailed expertise, and through the inclusion of robust data and authoritative recommendations, businesses can establish a reliable sealing system tailored to their unique operational needs, thereby institutionalizing trust in both their processes and their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories