Cassette Seal Manufacturer | Heavy-Duty Multi-Lip Oil Seals

Field Notes on the modern cassette seal: what’s real, what matters

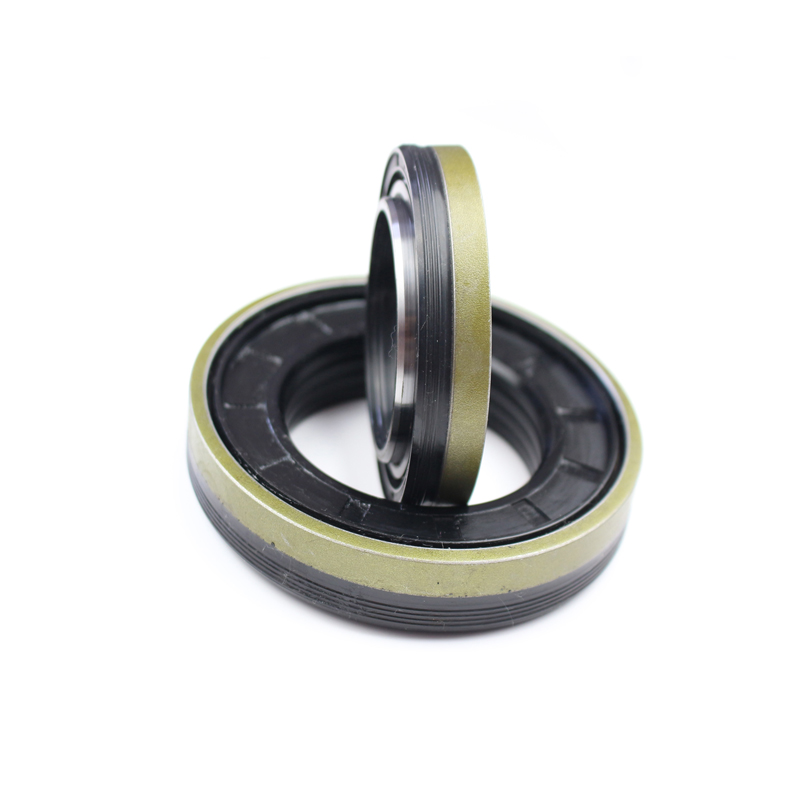

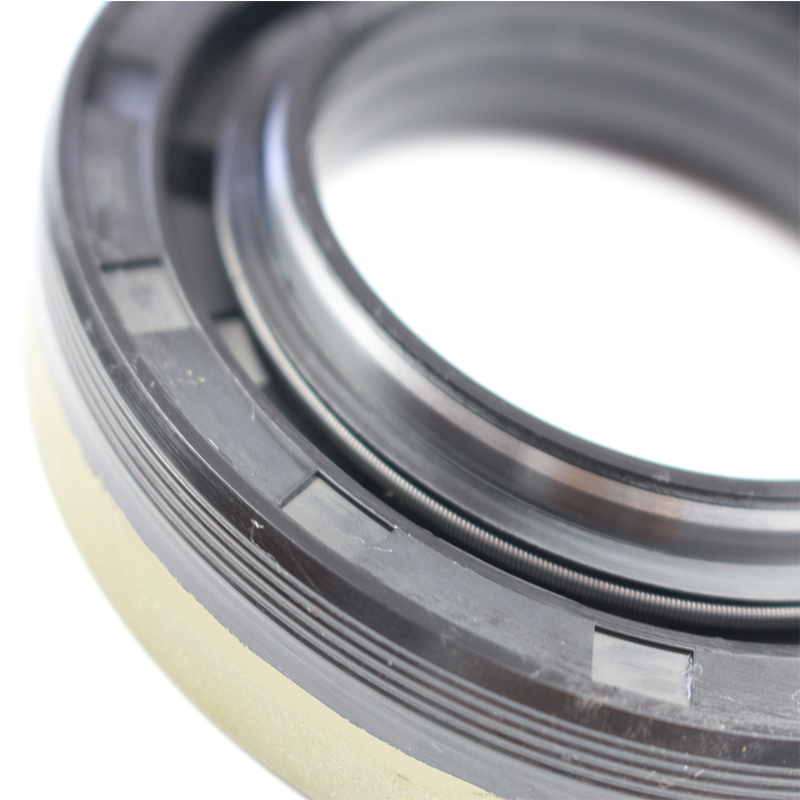

I’ve walked more than a few shop floors where an axle rebuild lives or dies by contamination control. And, to be honest, the product that keeps popping up in those conversations is the cassette seal—a compact, unitized guardian that shrugs off mud, slurry, and grit. Built for heavy-duty hubs, axles, and power-transmission ends, it’s designed to retain fluid while blocking everything else. The unitized construction means you don’t need a perfect shaft finish or specific hardness, which saves real money in the field.

At-a-glance specifications

| Parameter | Typical Range (≈, real-world may vary) |

|---|---|

| Shaft diameters | 30–220 mm |

| Temperatures | -40 to +120 °C (fluoroelastomer to 150 °C) |

| Surface speed | up to ≈10 m/s |

| Pressure capability | up to ≈0.5 bar (non-pressure design) |

| Service life | 6,000–12,000 hrs depending on media and duty |

| Materials | NBR, FKM, PTFE lips; low-carbon steel case; labyrinth rings |

| Standards touchpoints | ISO 6194, ASTM D2000/D471, IP69K (DIN 40050-9) testing |

Process flow: from material to validation

- Materials: oil- and abrasion-resistant NBR or FKM; PTFE for low-friction lips; phosphate-coated or stainless steel cases.

- Methods: unitized assembly with multi-lip labyrinth, spring-energized primary lip, grease-packed exclusion stages.

- Testing: lip torque and runout (ISO 6194), oil swell/compatibility (ASTM D471), rubber classification (ASTM D2000), high-pressure wash (IP69K), salt spray on metal parts (ASTM B117).

- Service life checks: bench durability to 1,000+ hrs, then field audits (ag and construction fleets) for 1–2 seasons.

- Industries: construction, agricultural, mining, forestry, on-/off-highway hubs and transfer boxes.

Where a cassette seal shines

- Wheel hubs and axle ends in harvesters and loaders—muddy harvests are the acid test.

- Mining haul trucks—abrasive dust plus thermal cycling.

- Forestry equipment—pressure washing after resin-heavy shifts.

Advantages? Multi-lip exclusion, grease reserve, shaft-friendly unitized design, and surprisingly forgiving installation. Many customers say they see fewer groove wear issues compared with traditional lip seals.

Vendor snapshot and customization

Origin: JULU INDUSTRY AREA, XINGTAI CITY, HEBEI PROVINCE, CHINA 055250. Custom options typically include lip chemistry (NBR/FKM/PTFE), dust lip count, case coatings, and dimensional tweaks for legacy hubs.

| Vendor | Customization | Certifications | Lead time | Notes |

|---|---|---|---|---|

| YJM Cassette Seals | High (materials, lips, coatings) | ISO 9001; material reports | ≈3–6 weeks | Cost-competitive, flexible MOQs |

| Global Brand A | Medium | ISO 9001/14001 | ≈6–10 weeks | Broad catalog |

| Global Brand B | Medium–High | IATF 16949 | ≈8–12 weeks | Premium pricing |

Field case and feedback

A Midwest grain co-op swapped legacy hub seals for a cassette seal on 40 combines. After 900 engine hours, oil consumption was unchanged, and particles >14 μm in hub oil dropped by around 35% (per ISO 4406 cleanliness checks). Operators mentioned, “less weeping after washdowns”—not scientific, but it tracks with the labyrinth design.

Another fleet in open-pit mining reported fewer emergency pulls during rainy season. They credit the grease-charged dust stages; I’d say installation discipline helped too.

Certifications, testing, and what to ask a supplier

- Ask for ISO 9001 certificates and PPAP/IMDS if you’re automotive-adjacent.

- Request ASTM D471 oil compatibility data for your specific gear oil or bio-hydraulic fluid.

- Confirm IP69K or equivalent washdown testing if you pressure-wash daily.

- Check installation guides—torque, runout, and shaft chamfer matter even with a cassette seal.

References

- ISO 6194 (Rotary shaft lip-type seals) – International Organization for Standardization.

- ASTM D2000 (Classification System for Rubber Products in Automotive Applications) – ASTM International.

- ASTM D471 (Rubber Property—Effect of Liquids) – ASTM International.

- DIN 40050-9 / ISO 20653 (IP69K ingress protection) – DIN/ISO.

- ISO 4406 (Hydraulic fluid cleanliness code) – International Organization for Standardization.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories