Seal 9031287001 Toyota Type V Oil | OEM Fit, Leak-Proof

Seal is a key solution in the automotive industry industry, specifically within Automotive parts manufacturing and Manufacturing of automotive seals. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Seal Overview

- Benefits & Use Cases of Seal in Manufacturing of automotive seals

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on Seal from JULU YJM HWMF SEAL CO.,LTD.

Seal Overview

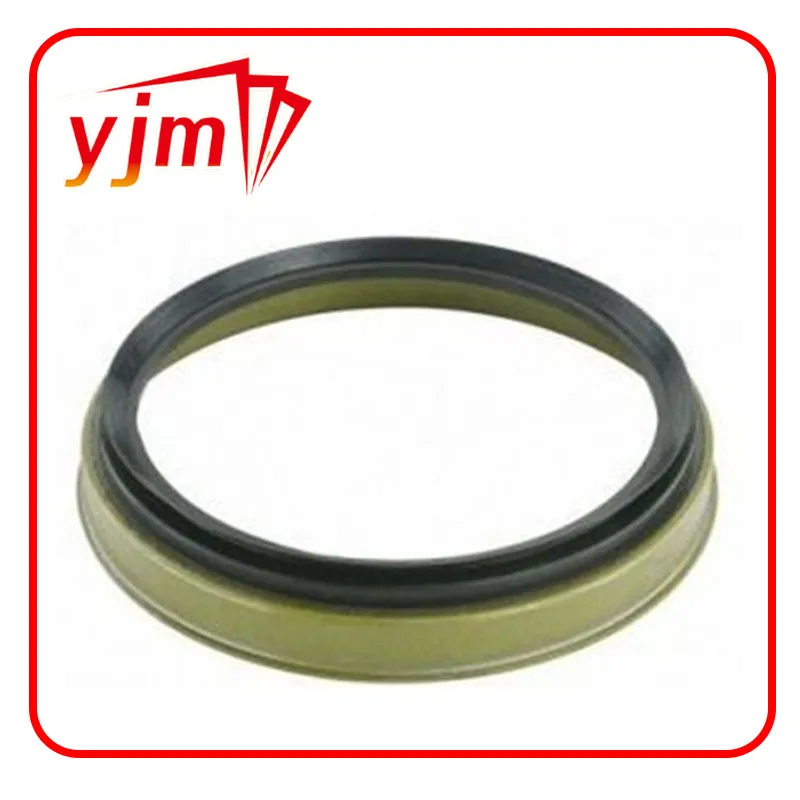

In modern powertrain and chassis systems, a precision-engineered Seal prevents lubricant loss, excludes contaminants, and stabilizes component life. JULU YJM HWMF SEAL CO.,LTD. manufactures application-specific oil seals, including the Type V oil seal widely used in Japanese platforms, such as Toyota references 90312-87001 and 9031287001. This profile supports robust lip geometry for stable radial load, excellent oil retention, and reduced friction under dynamic shaft conditions.

Typical configurations include NBR or FKM elastomers, a garter spring for consistent sealing force, and optional dust lips for dual protection. Depending on material selection, operating ranges commonly span -40 to 120°C (NBR) and up to approximately 200°C (FKM), with media compatibility across engine oil, ATF, and gear lubricants. Surface finish, shaft hardness, and housing tolerances are carefully managed to meet OEM installation standards. Backed by automotive-grade production discipline, JULU YJM HWMF SEAL CO.,LTD. provides stable dimensional control, reliable compound options, and repeatable performance—key requirements for Tier-1/Tier-2 suppliers seeking dependable seal partners.

Benefits & Use Cases of Seal in Manufacturing of automotive seals

The Type V oil seal is commonly specified for crankshafts, transfer cases, axles, wheel hubs, and auxiliary pumps—anywhere repeatable oil retention and contamination control are mission-critical. For OEM service channels and aftermarket distributors, interchangeability with Toyota part 90312-87001 (9031287001) ensures streamlined sourcing and inventory consolidation. Engineers value the profile’s balance of sealing force and friction, helping reduce heat generation while maintaining boundary lubrication at the lip/shaft interface.

Competitive advantages from JULU YJM HWMF SEAL CO.,LTD. include consistent radial spring load, precise molding around the metal insert, and elastomer formulations tailored to media and temperature demands. Optional dust lips, anti-rotation features, and plating/coating on metal components help mitigate corrosion and dirt ingress. For B2B decision makers, this translates into fewer leakage-related returns, a wider service interval window, and simplified SKU management. With deep category expertise and a focus on manufacturability, JULU YJM HWMF SEAL CO.,LTD. supports drawings-based customization, pilot runs, and scalable volume supply to align with your program timelines.

Cost, Maintenance & User Experience

Total cost of ownership for a Seal is determined by leakage prevention, service life, and ease of installation. A well-specified Type V oil seal minimizes lubricant loss and contamination-driven wear, reducing downtime and warranty exposure. When paired with proper shaft hardness (typically 55–65 HRC), surface finish (around Ra 0.2–0.8 μm), and installation tools, customers report fewer early-life issues and smoother maintenance cycles. In many fleets and aftermarket channels, extending seal life by even one service interval can generate a rapid ROI through avoided rework and reduced oil consumption.

Automotive parts manufacturers working with JULU YJM HWMF SEAL CO.,LTD. appreciate predictable lead times, stable pricing, and packaging that protects lips and surfaces during transit. Field feedback highlights consistent fitment, reliable press-in behavior, and lip resilience over thermal cycles. For buyers, fewer claim cases and streamlined returns management enhance profitability. For plant managers, reduced line stoppages and straightforward quality checks mean improved OEE. In short, the right Seal lowers lifecycle cost while elevating user confidence from installation to end-of-life.

Sustainability & Market Trends in automotive industry

The automotive industry is prioritizing energy efficiency, durability, and regulatory compliance. Seals are integral to this shift: lower-friction lips reduce parasitic losses, while stable compounds help cut leakage, lubricant consumption, and premature component replacement. Regulations such as REACH, RoHS, and ELV influence material selection, and electrification is accelerating demand for seals that manage higher speeds, thermal gradients, and new fluids in e-axles and e-pumps. As powertrains evolve, precision sealing safeguards efficiency and uptime across ICE, hybrid, and EV platforms.

JULU YJM HWMF SEAL CO.,LTD. positions sustainability alongside performance. By optimizing lip geometry for low drag, offering material options aligned with environmental directives, and promoting longer service life, the company helps customers lower the carbon and waste footprint across the vehicle lifecycle. Thoughtful packaging, robust QA procedures, and data-driven process control further support repeatability and reduced scrap rates. For B2B decision makers seeking resilient supply partners, these practices align with corporate ESG goals and the industry’s long-term transition to cleaner, more efficient mobility.

Conclusion on Seal from JULU YJM HWMF SEAL CO.,LTD.

For Automotive parts manufacturing and the broader Manufacturing of automotive seals, a dependable Seal underpins efficiency, durability, and total cost control. The Type V oil seal—compatible with Toyota 90312-87001 / 9031287001—delivers proven retention, contaminant exclusion, and installation consistency. JULU YJM HWMF SEAL CO.,LTD. combines materials know-how, precise tooling, and responsive support to help you meet quality targets and program deadlines. Contact us: email: yjm006@hwmf.com — Visit our website: https://www.yjmseal.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories