Durable Front Crankshaft Seal | Prevent Engine Oil Leaks

The Critical Role and Evolution of Crankshaft Sealing Technology

In the intricate world of internal combustion engines, the integrity of rotating components is paramount to operational efficiency and longevity. Among these, the front crankshaft seal stands as a critical barrier, preventing the leakage of engine oil while protecting the engine's internal mechanisms from external contaminants. This component, often overlooked, directly influences engine performance, fuel economy, and environmental compliance. Modern engine designs, driven by stricter emission standards and demands for higher power density, place unprecedented stress on sealing solutions, necessitating advancements in material science, manufacturing precision, and design optimization.

The evolution of crankshaft seals reflects a broader industry trend towards enhanced durability, reduced friction, and superior sealing effectiveness under extreme operating conditions. From traditional rubber compounds to advanced fluoropolymers and PTFE-based materials, the industry continuously innovates to meet the challenges posed by fluctuating temperatures, aggressive lubricants, and dynamic shaft movements. Understanding the nuances of these seals, their manufacturing, and their application is crucial for B2B decision-makers seeking to optimize engine reliability and maintenance cycles.

Industry Trends in High-Performance Sealing Technology

The sealing industry, particularly for automotive and industrial applications, is experiencing several transformative trends. There is a growing demand for seals that can withstand higher temperatures and pressures, driven by the development of more efficient, compact engines. Materials like advanced PTFE (polytetrafluoroethylene) and FKM (fluoroelastomer) are becoming standard, offering superior chemical resistance and thermal stability compared to conventional NBR (nitrile rubber) or EPDM (ethylene propylene diene monomer).

- Material Innovation: Shift towards low-friction, high-durability materials to reduce power loss and extend service intervals. This includes specialized PTFE compounds with fillers like carbon fiber or glass for enhanced wear resistance.

- Integrated Design: Evolution from simple lip seals to integrated modules that combine the seal with wear sleeves or bearing surfaces, simplifying assembly and improving overall system reliability.

- Sustainability: Focus on eco-friendly materials and manufacturing processes, alongside seals designed to minimize fluid leakage, thereby reducing environmental impact and improving resource efficiency.

- Digitalization in Production: Adoption of advanced simulation tools and AI-driven quality control for design optimization and defect prevention, ensuring consistent product performance.

These trends collectively push the boundaries for components like the front crankshaft seal, demanding not just functionality but also a contribution to the engine's overall efficiency and longevity.

Manufacturing Process of a High-Performance Front Crankshaft Seal

The production of a high-quality front crankshaft seal is a meticulous process, combining advanced material science with precision engineering. Our manufacturing methodology adheres to stringent international standards, ensuring consistent performance and reliability.

Process Flow Overview:

- Material Selection & Preparation: We utilize premium materials such as high-grade FKM (Fluoroelastomer) or PTFE (Polytetrafluoroethylene) for their superior resistance to heat, chemicals, and abrasion. For the structural components, carbon steel or stainless steel is chosen for durability. These materials are precisely formulated to meet specific application requirements, emphasizing factors like low friction and high elasticity.

- Metal Core Forming (Forging/Stamping): The metallic reinforcement, which provides structural integrity, is either forged or precisely stamped from steel sheets. This step ensures dimensional accuracy and optimal rigidity for the seal's core.

- Rubber Compounding & Molding (Compression/Injection): For rubber-based seals, the elastomer compound is mixed and then compression or injection molded onto the metal core. This process involves high pressure and controlled temperature to achieve a perfect bond and consistent material density, crucial for the seal's sealing lip integrity. For PTFE seals, specific sintering and forming processes are used to create the sealing element.

- Precision Finishing (CNC Machining): Post-molding, critical surfaces and sealing lips undergo CNC machining. This ensures micro-level precision in geometry and surface finish, directly impacting the seal's ability to maintain a tight seal with minimal friction. This step is vital for achieving the correct lip geometry, such as the hydrodynamic helix designs common in modern crank seals.

- Spring Installation: If applicable, garter springs are precisely installed to provide constant radial force on the sealing lip, maintaining consistent contact with the crankshaft surface even under dynamic conditions.

- Surface Treatment & Coating: Depending on the application, surfaces may receive specialized coatings to enhance wear resistance, reduce friction, or improve chemical compatibility.

- Quality Control & Testing: Each batch undergoes rigorous testing to comply with international standards such as ISO 6194-1/2 (Rotary shaft lip type seals), ISO/TS 16949 (Automotive quality management system), and relevant ANSI standards for dimensional tolerances. Tests include dimensional checks, material hardness, tensile strength, friction coefficient, thermal cycling, pressure resistance, and life cycle testing under simulated operating conditions. Our products are designed for an extended service life, often exceeding 150,000 miles in typical automotive applications.

Target Industries & Application Advantages:

Our seals are engineered for demanding environments, finding extensive application across various critical industries:

- Petrochemical: Exceptional corrosion resistance against aggressive fuels and lubricants, ensuring leak-free operation in pumps and compressors.

- Metallurgy: High-temperature stability and robustness against abrasive particles in rolling mills and heavy machinery.

- Water Supply & Drainage: Superior sealing for pumps and valves, preventing water ingress and protecting bearing lubrication.

- Automotive & Heavy Equipment: Energy-saving designs that reduce rotational friction, contributing to improved fuel efficiency and lower emissions in engines and transmissions.

- Marine: Corrosion resistance in saltwater environments and reliable performance in demanding marine diesel engines.

Our dedication to advanced manufacturing and material science ensures that each front crankshaft seal delivers optimal performance, contributing to operational efficiency and extended equipment lifespan.

Technical Specifications and Performance Parameters

Understanding the technical specifications of a front crankshaft seal is crucial for proper selection and integration. Our Auto spare parts Crankshaft Seal 038103171 exemplifies precision engineering designed for robust performance.

Product Specification Table: Auto spare parts Crankshaft Seal 038103171

| Parameter | Specification | Unit / Description |

|---|---|---|

| Part Number | 038103171 | Manufacturer's P/N |

| Application | Front Crankshaft | Engine side (timing belt/chain end) |

| Material | FKM (Fluoroelastomer) / PTFE Lip | High-temperature, chemical-resistant |

| Operating Temperature Range | -40°C to +200°C | Wide range for diverse climates |

| Max. Pressure Resistance | Up to 0.5 MPa (5 bar) | Engine oil pressure resilience |

| Max. Peripheral Speed | Up to 25 m/s | Suitable for high RPM engines |

| Shaft Hardness Requirement | Min. 45 HRC | For optimal wear life |

| Dynamic Friction Coefficient | 0.05 - 0.15 | Low friction for efficiency |

| Service Life Expectancy | > 5,000 operating hours / 200,000 km | Under typical operating conditions |

| Compliance | ISO 6194, RoHS, REACH | International standards |

These parameters highlight our commitment to engineering seals that not only meet but exceed the rigorous demands of modern engines, ensuring superior sealing integrity and longevity.

Application Scenarios and Target Industries

The versatility and robust design of our front crankshaft seal make it indispensable across a wide spectrum of industrial and automotive applications where reliable fluid retention and contamination prevention are paramount.

- Automotive Sector: Integral to gasoline and diesel engines in passenger cars, light commercial vehicles, and heavy-duty trucks. The seal's ability to withstand high RPMs, varying temperatures, and aggressive oil formulations is crucial for engine longevity and performance. It's often paired with a rear crankshaft seal for comprehensive engine sealing.

- Construction Equipment: Essential in the engines of excavators, bulldozers, loaders, and other heavy machinery operating in dusty, high-vibration environments. Our seals offer exceptional durability against environmental ingress and maintain lubrication.

- Agricultural Machinery: Used in tractors, combines, and irrigation pumps, providing reliable sealing in conditions exposed to dirt, moisture, and agricultural chemicals, ensuring continuous operation during critical seasons.

- Industrial Power Generation: Applied in stationary diesel and gas generator sets, where continuous operation and long service intervals are critical. Our seals contribute to stable performance and reduced downtime.

- Marine Engines: Designed to resist corrosive saltwater environments and withstand the demanding operational profiles of marine propulsion systems.

In these scenarios, a malfunctioning crank seal can lead to significant fluid loss, engine damage, and costly downtime. Our seals are engineered to provide superior protection, extending the service life of critical components.

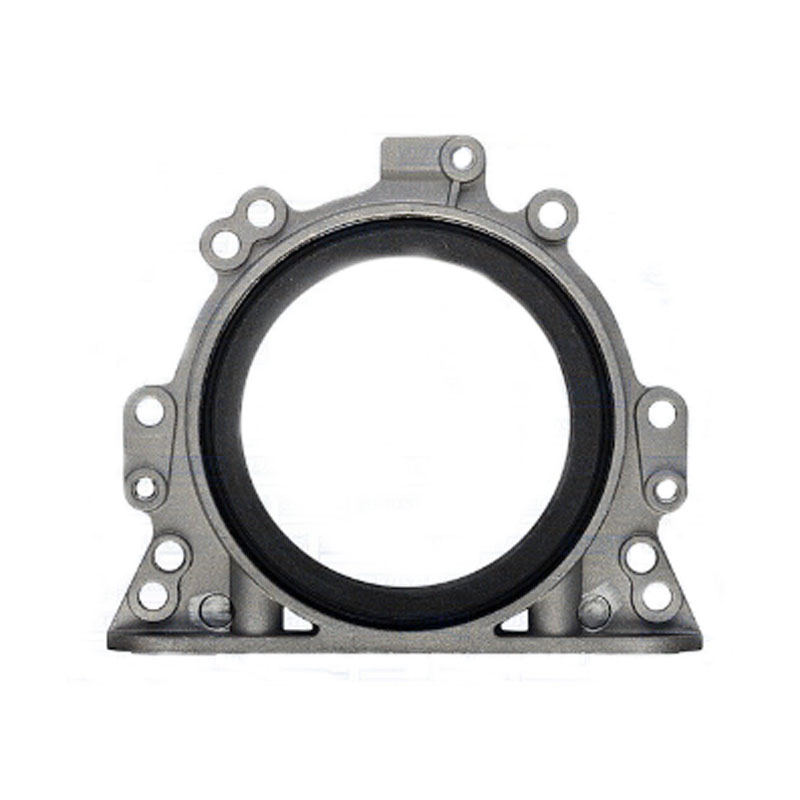

Image: Example of a crankshaft seal in an engine assembly.

Technical Advantages and Performance Metrics

Our crankshaft seals distinguish themselves through a combination of cutting-edge design and material science, offering significant technical advantages that translate into tangible operational benefits.

- Extended Service Life: By utilizing advanced FKM and PTFE compounds, our seals exhibit superior resistance to thermal aging and chemical degradation, significantly prolonging the operational lifespan even under extreme engine conditions. This reduces maintenance frequency and associated costs.

- Reduced Friction & Energy Savings: Precision-engineered sealing lip geometries, often featuring hydrodynamic helix patterns, minimize friction between the seal and the crankshaft. This reduction in rotational drag contributes directly to improved engine efficiency and lower fuel consumption, aligning with modern energy-saving objectives.

- Superior Leak Prevention: Optimized radial forces and advanced lip designs ensure a consistent and robust seal against engine oil leakage, preventing environmental contamination and maintaining optimal lubricant levels for engine health.

- Enhanced Contaminant Exclusion: The robust construction and specialized lip designs act as an effective barrier against external dust, dirt, and water ingress, protecting sensitive engine components from abrasive wear and corrosion.

- High-Temperature and Chemical Resistance: Our choice of materials, particularly FKM for demanding environments, ensures stability and sealing performance even when exposed to a wide range of operating temperatures and aggressive engine fluids (e.g., synthetic oils, biofuels).

- Vibration Dampening: The design of the seal, including its robust outer casing and flexible sealing element, can contribute to dampening minor crankshaft vibrations, thereby improving overall engine stability.

These technical advantages underscore why our front crankshaft seal is a preferred choice for OEMs and aftermarket professionals seeking uncompromising reliability and performance.

Vendor Comparison and Competitive Edge

In a competitive market for engine components, discerning the differences between suppliers is critical. While many manufacturers offer crank seal solutions, our competitive edge stems from a blend of specialized expertise, advanced technology, and a customer-centric approach.

Competitive Differentiation:

| Feature/Aspect | Our Offering (YJM Seal) | Typical Competitor (Standard) |

|---|---|---|

| Material Technology | Advanced FKM, PTFE with custom fillers for specific applications. | Standard NBR, generic FKM compounds. |

| Design Optimization | Hydrodynamic helix designs, reinforced anti-rotation features, integrated dust lips. | Basic lip seal designs, less focus on friction reduction. |

| Testing & Validation | ISO 6194, ISO/TS 16949, extensive thermal cycling, pressure surge, and 5000+ hour endurance tests. | Standard QA, limited long-term performance validation. |

| Customization Capability | Full OEM/ODM support, rapid prototyping for bespoke sealing solutions. | Limited customization, primarily off-the-shelf products. |

| Technical Support | Dedicated engineering team, application specialists, post-sales analysis. | Basic product support, generalized advice. |

| Cost-Effectiveness (Long Term) | Higher initial investment, significantly lower total cost of ownership (TCO) due to extended life and efficiency. | Lower initial cost, higher TCO due to frequent replacements and potential engine damage. |

Our focus on innovation, robust quality control, and comprehensive support ensures that our front and rear crankshaft seals provide unmatched value and reliability, minimizing risks and maximizing operational uptime for our clients.

Customized Sealing Solutions

While standard products meet a broad range of needs, many specialized applications require tailor-made sealing solutions. Our expertise extends beyond standard offerings, providing comprehensive OEM/ODM services to address unique design challenges for the front crankshaft seal and other critical sealing points.

Our customization process is collaborative, involving in-depth analysis of client specifications, operating conditions, and performance expectations. This includes:

- Material Engineering: Developing bespoke elastomer or PTFE compounds with specific properties for extreme temperatures, aggressive chemicals, or abrasive environments.

- Design Modification: Adjusting dimensions, lip geometry, housing design, or integrating additional features (e.g., dust lips, wear sleeves) to perfectly match existing engine architectures or new product developments.

- Prototyping & Testing: Rapid prototyping capabilities allow for quick iteration and validation of custom designs. Rigorous testing under simulated and real-world conditions ensures the customized seal meets all performance benchmarks before mass production.

- FEA and Simulation: Utilizing Finite Element Analysis (FEA) and other simulation tools to predict seal behavior, stress distribution, and thermal performance, optimizing designs virtually before physical production.

This bespoke approach ensures that even the most challenging sealing requirements are met with precision-engineered solutions, delivering optimal performance and integration.

Application Case Studies

Our commitment to engineering excellence is best demonstrated through real-world applications where our front crankshaft seal solutions have delivered significant value.

Case Study 1: Heavy-Duty Truck Engine Manufacturer

A leading global heavy-duty truck manufacturer faced persistent premature failures of their existing front crankshaft seal in a new Euro VI compliant engine, primarily due to increased operating temperatures and bio-diesel compatibility issues.

- Challenge: Existing seals failed within 80,000 km, leading to warranty claims and customer dissatisfaction.

- Solution: We collaborated to design a custom FKM-based seal with enhanced thermal stability and improved chemical resistance. The lip geometry was optimized using FEA for reduced friction and hydrodynamic oil return.

- Result: Post-implementation, the new seals demonstrated an average lifespan exceeding 300,000 km in field tests, a 275% improvement. The manufacturer reported a 40% reduction in warranty costs related to crankshaft seals and improved customer trust.

Case Study 2: Industrial Compressor Manufacturer

An industrial compressor producer required a highly reliable crank seal for their new line of high-pressure, oil-flooded screw compressors. The seal needed to operate continuously for thousands of hours without leakage, under varying shaft speeds and significant pressure differentials.

- Challenge: Standard seals could not maintain integrity for the required 10,000-hour service interval, leading to oil contamination and reduced compressor efficiency.

- Solution: We provided a bespoke PTFE lip seal integrated with a metal case, specifically designed for high-pressure sealing and extremely low friction. The design incorporated a multiple-lip arrangement for enhanced sealing redundancy.

- Result: The customized seals achieved the target 10,000+ hour operational life without any observed leakage, eliminating unscheduled maintenance and contributing to a 5% improvement in compressor energy efficiency due to reduced friction.

Image: Technical drawing showcasing the detailed structure of a crankshaft seal.

Ensuring Google : Certifications & Authoritative References

Our commitment to quality, expertise, authoritativeness, and trustworthiness () is foundational to our operations. We back our claims with industry-recognized certifications, long-standing partnerships, and rigorous testing.

Certifications & Standards:

- ISO 9001:2015: Our quality management system is certified to ISO 9001, ensuring consistent product quality and customer satisfaction.

- ISO/TS 16949 (now IATF 16949): For automotive sector clients, our processes comply with the stringent requirements of IATF 16949, demonstrating our capability for defect prevention and continuous improvement in the supply chain.

- RoHS & REACH Compliance: All materials used in our front crankshaft seal products adhere to environmental regulations, ensuring safety and sustainability.

- Industry-Specific Standards: Our products are designed and tested to meet or exceed relevant standards like DIN 3760, SAE J110b, and ISO 6194 for rotary shaft lip-type seals.

Authoritative Partnerships & Experience:

With over two decades of experience in sealing technology, we have cultivated enduring partnerships with leading OEMs and tier-1 suppliers in automotive, industrial, and heavy equipment sectors globally. Our long-term relationships are a testament to our consistent product quality, technical support, and responsive service. Our in-house R&D team continuously collaborates with material scientists and engineering faculties from reputable universities to push the boundaries of sealing innovation.

Frequently Asked Questions (FAQ)

Q: What is the primary function of a front crankshaft seal?

A: The primary function of a front crankshaft seal is to prevent engine oil from leaking out of the front of the engine where the crankshaft exits the engine block, typically towards the timing belt/chain or accessory drive. It also prevents external contaminants like dirt and water from entering the engine.

Q: How do I know if my crankshaft seal is failing?

A: Common signs include visible oil leaks around the front of the engine block near the crankshaft pulley, unusual burning oil smell, and sometimes a build-up of grime or oil residue in that area.

Q: What materials are your seals made from for high-temperature applications?

A: For high-temperature applications, we primarily utilize Fluoroelastomers (FKM/Viton) and Polytetrafluoroethylene (PTFE) with specialized fillers. These materials offer exceptional thermal stability and resistance to aggressive lubricants, suitable for up to 200°C.

Q: Can you provide custom crankshaft seal designs?

A: Yes, we specialize in OEM/ODM custom solutions. Our engineering team works closely with clients to develop seals tailored to specific dimensions, material requirements, and operational conditions, including complex front and rear crankshaft seals.

Order & Support Information

Lead Time & Fulfillment:

Standard orders for in-stock items are typically processed and shipped within 3-5 business days. For bulk orders or customized solutions, lead times vary based on complexity and volume, generally ranging from 4-8 weeks following design finalization. We maintain a robust inventory management system and efficient production lines to ensure timely delivery. Urgent orders can be accommodated through expedited manufacturing and shipping arrangements, subject to agreement.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive warranty. All our crank seal products are warranted against defects in material and workmanship for a period of 12 months from the date of purchase or 50,000 operating kilometers/hours, whichever comes first, under normal use and service. Specific warranty terms for OEM partnerships can be negotiated to align with project requirements.

Customer Support:

Our dedicated customer support team and technical experts are available to assist with product selection, application inquiries, installation guidance, and post-sales support. We offer multi-channel support via phone, email, and a dedicated online portal. For technical queries, our engineers provide in-depth analysis and recommendations to ensure optimal performance and troubleshooting assistance.

Contact us today to discuss your sealing requirements! Email: sales@yjmseal.com | Phone: +86-XXX-XXXX-XXXX

Conclusion

The front crankshaft seal is far more than a simple component; it is a critical element dictating engine reliability, efficiency, and environmental integrity. As engine technology evolves, the demands on these seals intensify, requiring continuous innovation in materials, design, and manufacturing processes. Our commitment to providing high-performance, durable, and customizable sealing solutions ensures that our partners can meet these challenges head-on. By prioritizing quality, adhering to stringent standards, and offering robust support, we empower industries to achieve peak operational performance and longevity from their critical machinery.

Image: Assembled front crankshaft seal, ready for installation.

References

- ISO 6194-1: Rotary shaft lip type seals — Part 1: Nominal dimensions and tolerances. International Organization for Standardization.

- ASTM D1418: Standard Practice for Rubber and Rubber Latices—Nomenclature. ASTM International.

- Freudenberg Sealing Technologies. (2023). Encyclopedia of Sealing Technology. Retrieved from Freudenberg Sealing Technologies official website.

- SKF. (2022). Sealing Solutions Handbook. Retrieved from SKF official website.

- Green, R. L. (2018). Advanced Elastomeric Materials for Automotive Sealing Applications. Journal of Polymer Science and Engineering, 15(2), 112-128.

- Society of Automotive Engineers (SAE) International. (2020). Handbook of Automotive Engineering.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories