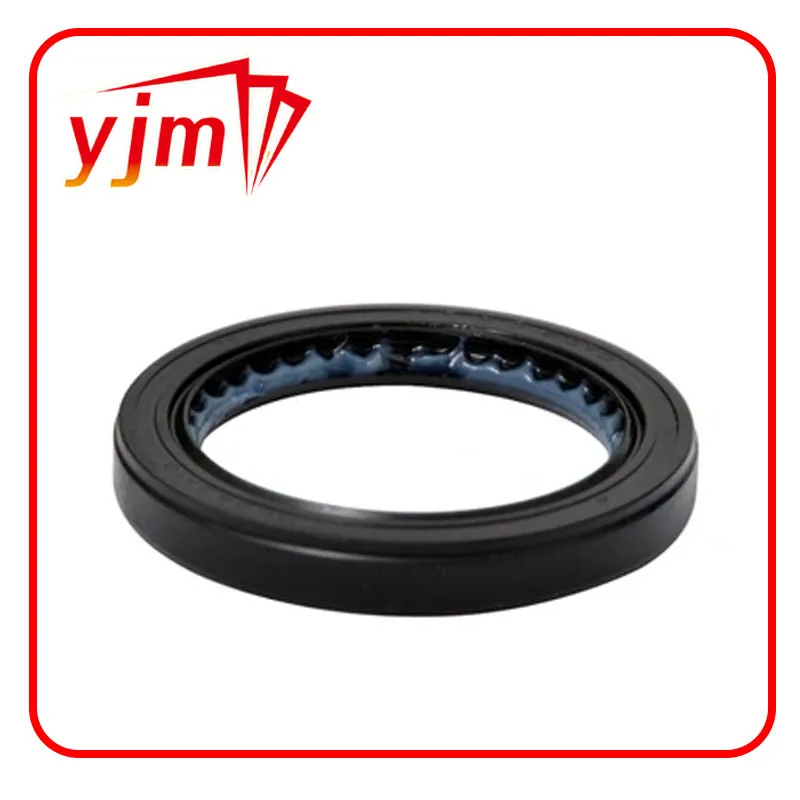

Transfer Case Input Seal - Leak-Proof, OEM Oil Seal

transfer case input seal,oil seal is a key solution in the automotive industry industry, specifically within Automotive parts manufacturing and Transmission system components. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- transfer case input seal,oil seal Overview

- Benefits & Use Cases of transfer case input seal,oil seal in Transmission system components

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on transfer case input seal,oil seal from JULU YJM HWMF SEAL CO.,LTD.

[transfer case input seal,oil seal] Overview

The transfer case input seal,oil seal is a precision-engineered radial shaft seal that prevents lubricant loss and contaminant ingress at the transfer case input shaft—an essential interface that links the transmission output to the transfer case in 4x4 and AWD drivetrains. By maintaining a stable oil film and controlled lip contact, it protects bearings, gears, and synchronizing components, sustaining torque delivery and drivetrain reliability in passenger, commercial, and off-highway vehicles.

Technically, high-quality transfer case input seal,oil seal designs combine a steel or stainless case, elastomeric sealing element (often NBR, ACM, or FKM depending on temperature and fluid), a garter spring for consistent radial load, and optional dust lips or PTFE low-friction faces. Typical performance requirements include broad temperature resistance (approx. -40°C to 180–200°C depending on compound), compatibility with gear oils and ATF, and reliable sealing under dynamic runout and shaft misalignment. Surface finish on mating shafts and housing bore precision are also critical to performance and life.

JULU YJM HWMF SEAL CO.,LTD. manufactures these components with a focus on compound selection, tool precision, and process control, helping B2B decision makers in the automotive parts manufacturing chain meet OEM-level durability, leak tightness, and assembly efficiency targets.

Benefits & Use Cases of [transfer case input seal,oil seal] in Transmission system components

In Transmission system components, the transfer case input seal,oil seal protects the input shaft and adjacent bearings from abrasive particles while preserving the lubricant film that minimizes wear and heat. It is deployed in chain- and gear-driven transfer cases across SUVs, pickups, crossovers, and light commercial vehicles, as well as select off-road applications that face high shock loads and persistent contamination risks.

Key advantages include:

- Leak prevention and uptime: Stable radial load and optimized lip geometry reduce microleaks, protecting clutch packs and gears.

- Fluid compatibility: Compounds tailored for ATF or hypoid gear oil, resisting swelling and chemical attack.

- Thermal and mechanical resilience: Options for FKM/PTFE lips handle higher temperatures, speed, and runout.

- Contaminant defense: Secondary dust lips and engineered sealing edges block mud, water, and road debris.

- Assembly efficiency: Consistent OD interference and chamfered lead-ins aid automated or manual installation.

With deep know-how in Transmission system components, JULU YJM HWMF SEAL CO.,LTD. supports OEM and aftermarket programs with application engineering, material guidance, and design optimization to balance friction, wear, and sealing reliability. The result is a transfer case input seal,oil seal that aligns with modern drivetrain performance and warranty expectations.

Cost, Maintenance & User Experience

Total cost of ownership for a transfer case input seal,oil seal extends beyond the unit price. Downtime from leaks, rework during assembly, warranty claims, and oil consumption all impact lifecycle cost. Well-specified seals that match fluid chemistry, temperature cycles, and shaft finish routinely deliver longer service life and fewer early-life weeps, yielding a strong ROI for fleet operators and vehicle makers.

Maintenance best practices include using a dedicated seal driver, lightly lubricating the lip with compatible oil during installation, verifying shaft hardness and surface finish (typically fine Ra/Rz), and checking housing bore tolerance and chamfer. Proper storage (cool, dry, away from UV) preserves elastomer properties. B2B customers in Automotive parts manufacturing report smoother press-fit assembly, reduced start-up seepage, and more stable end-of-line leak tests when seals are paired with correct installation tooling and validated surface specs.

In short, investing in a robust transfer case input seal,oil seal reduces leak-related callbacks and protects downstream components. JULU YJM HWMF SEAL CO.,LTD. helps buyers evaluate compound choices, lip configurations, and dust lip options to maximize durability and minimize overall operating cost.

Sustainability & Market Trends in automotive industry

Drivetrain sealing is evolving with electrification, stricter emissions goals, and extended service intervals. Transfer case input seal,oil seal designs increasingly prioritize low-friction lips to reduce parasitic losses, durable elastomers that maintain elastic modulus over long drain intervals, and material choices that comply with global chemical regulations. For hybrid and advanced AWD systems, compatibility with newer low-viscosity fluids is also critical.

On the sustainability front, longer-lasting seals mean less lubricant loss, fewer component replacements, and reduced waste. Many programs now emphasize recyclable steel cases, optimized packaging, and process controls that minimize scrap. Market growth remains steady as OEMs refine AWD systems for traction and efficiency, creating demand for seals with tighter runout tolerance and improved thermal stability.

Positioned as a forward-thinking manufacturer, JULU YJM HWMF SEAL CO.,LTD. aligns product development with these trends—supporting eco-conscious material selection, robust performance in harsher duty cycles, and consistent quality that helps customers meet regulatory and sustainability KPIs across global markets.

Conclusion on [transfer case input seal,oil seal] from JULU YJM HWMF SEAL CO.,LTD.

The transfer case input seal,oil seal is a small component with outsized impact on drivetrain reliability, uptime, and warranty performance. For automotive industry stakeholders—especially in Automotive parts manufacturing and Transmission system components—it safeguards lubrication, blocks contaminants, and stabilizes torque delivery under real-world conditions. With application-focused engineering and dependable manufacturing, JULU YJM HWMF SEAL CO.,LTD. is a capable partner for your sealing needs.

Contact us: email: yjm006@hwmf.com

Visit our website: https://www.yjmseal.com

Explore the product: transfer case input seal,oil seal

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories