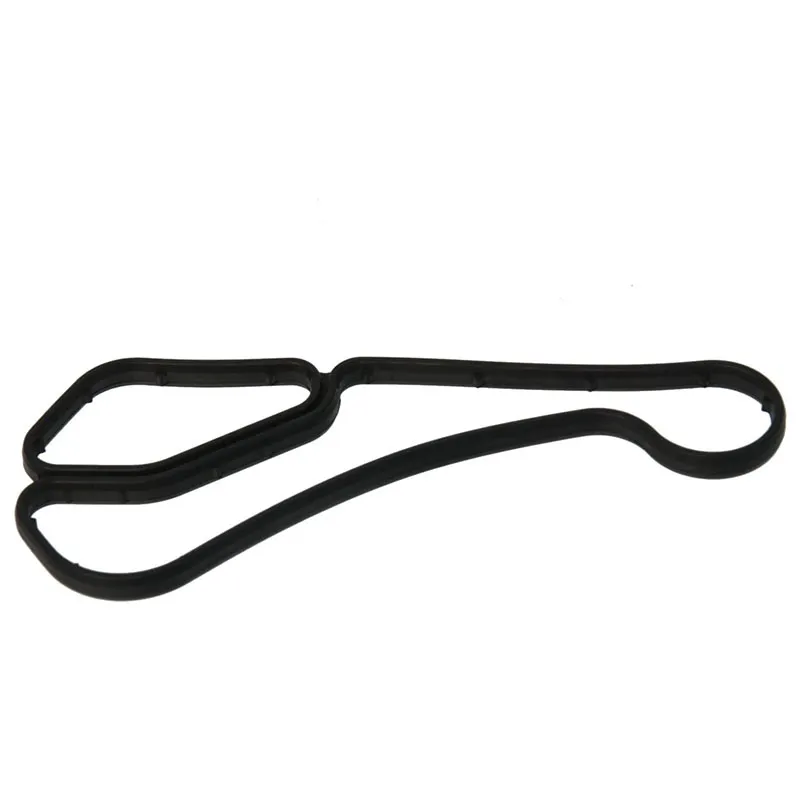

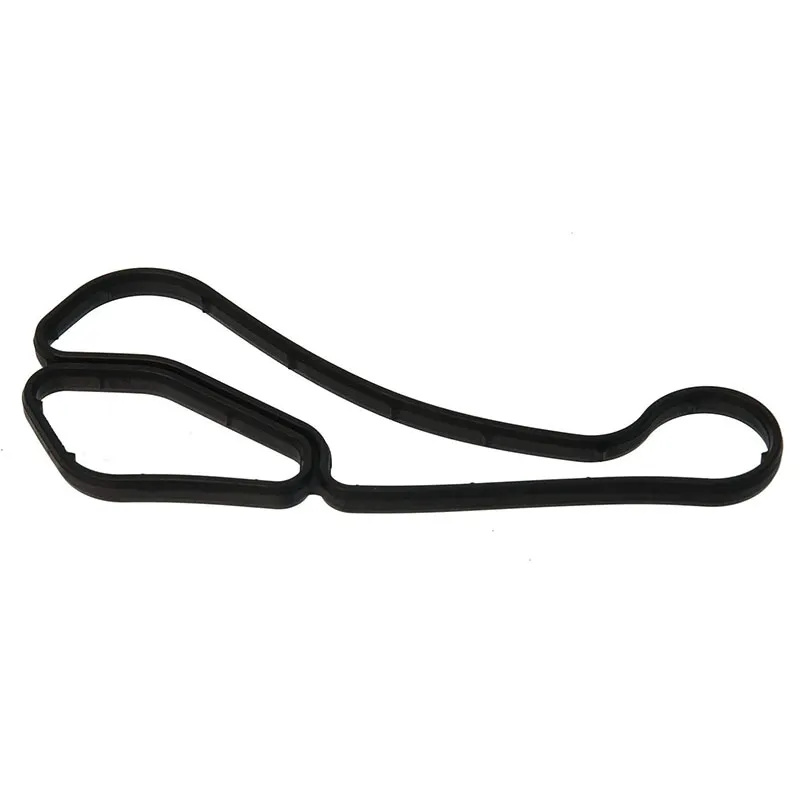

Premium Oil Cooler Gasket | Prevent Leaks, Direct Fit 11427525335

The Critical Role of Oil Cooler Gaskets in Modern Engineering

In the intricate architecture of internal combustion engines and various industrial machinery, precision sealing components are paramount to operational efficiency and longevity. Among these, the Oil Cooler Gasket plays a uniquely critical role. Specifically, components like the Oil Cooler to Oil Filter Housing 11427525335 are engineered to prevent leakage of lubricating oil, ensuring optimal heat exchange and maintaining system integrity under extreme operating conditions. This article delves into the technical specifications, manufacturing intricacies, and strategic advantages offered by high-performance oil cooler gaskets, providing B2B decision-makers and engineers with comprehensive insights into their indispensable value.

A robust sealing solution is not merely a component; it is a guarantor of performance, preventing fluid loss, contamination, and ultimately safeguarding expensive machinery from premature failure. Understanding the engineering behind these gaskets is key to selecting the right product for demanding applications.

Current Industry Trends in Fluid Sealing Technology

The fluid sealing industry is continuously evolving, driven by several key trends. Increasingly stringent environmental regulations demand materials that offer superior long-term sealing performance, reducing emissions from oil leaks. Furthermore, the push for extended service intervals in automotive and industrial sectors necessitates gaskets with enhanced durability and resistance to degradation. Advancements in material science are leading to the development of elastomers and composite materials capable of withstanding higher temperatures, aggressive chemicals, and greater mechanical stresses. Digitalization also plays a role, with predictive maintenance strategies relying on sensors and data analytics to monitor gasket performance and predict potential failures before they occur. The focus is shifting towards "fit-and-forget" solutions, where the initial quality and material selection of a gasket, such as a high-grade Oil Cooler Gasket, ensure reliable operation throughout the equipment's lifespan.

- Material Innovation: Development of advanced elastomers (e.g., FKM, HNBR) and multi-layer steel (MLS) composites offering superior thermal and chemical resistance.

- Miniaturization & Integration: Designing compact sealing solutions that integrate multiple functions, optimizing space and assembly time.

- Sustainability Focus: Emphasis on manufacturing processes with reduced environmental impact and the use of recyclable materials where possible.

- Smart Sealing Solutions: Incorporation of sensor technology for real-time monitoring of gasket integrity and performance.

Manufacturing Process of a High-Performance Oil Cooler Gasket

The production of a reliable Oil Cooler Gasket is a multi-stage process, meticulously controlled to ensure adherence to stringent performance specifications. Quality begins with the selection of raw materials and extends through every manufacturing step.

Key Materials Employed:

- Nitrile Butadiene Rubber (NBR): Excellent oil resistance and good temperature range.

- Hydrogenated Nitrile Butadiene Rubber (HNBR): Enhanced thermal stability and resistance to aggressive media compared to NBR.

- Fluoroelastomer (FKM/Viton®): Superior resistance to high temperatures, chemicals, and fuel, ideal for extreme conditions.

- Silicone (VMQ): Excellent flexibility and temperature resistance, though less oil-resistant than NBR/FKM.

- Composite Materials: Often layers of metal (steel) and elastomeric coatings for multi-layer steel (MLS) gaskets, providing robust sealing under high pressure and thermal cycling.

Manufacturing Process Flow:

- Material Preparation: Raw elastomer compounds are mixed with curing agents, fillers, and additives to achieve desired physical and chemical properties. For composite gaskets, metal cores are prepared.

- Molding/Die-Cutting: For elastomeric gaskets, compounds are typically compression molded or injection molded into precise forms. For flat gaskets, precision die-cutting from sheets ensures exact dimensions and clean edges.

- Vulcanization/Curing: The molded elastomer is subjected to heat and pressure to cross-link the polymer chains, giving the gasket its final elastic properties and durability.

- Surface Treatment (Optional): Some gaskets receive coatings (e.g., PTFE, silicone) to reduce friction, improve sealing under specific conditions, or enhance chemical resistance.

- Flash Trimming & Finishing: Excess material (flash) is carefully removed, and the gasket is inspected for any imperfections.

- Quality Control & Testing: Gaskets undergo rigorous checks including dimensional verification, material hardness testing, tensile strength, compression set, and oil compatibility tests. Leakage tests simulating real-world pressures and temperatures are standard.

Precision manufacturing ensures the integrity of every Oil Cooler Gasket.

Testing Standards & Service Life:

Adherence to international standards like ISO 9001 for quality management and ASTM standards for material testing is crucial. Performance tests, including thermal cycling, pressure resistance, and fluid compatibility (e.g., engine oil, coolant), ensure the gasket can withstand operating extremes. A well-manufactured Oil Cooler Gasket made from appropriate materials can offer a service life of 100,000 to 200,000 miles in automotive applications or several thousand operating hours in industrial machinery, depending on operating conditions and maintenance schedules.

Target Industries and Advantages:

- Automotive & Heavy Equipment: Preventing oil leaks in engine cooling systems, crucial for efficiency and environmental compliance. Our gaskets ensure optimal performance for the Oil Cooler to Oil Filter Housing 11427525335 in specific applications.

- Industrial Machinery: Maintaining hydraulic and lubrication system integrity in power generation, manufacturing, and construction equipment.

- Petrochemical & Marine: Providing corrosion resistance and chemical compatibility in harsh operating environments.

- Energy Saving: By preventing oil loss and maintaining system pressure, high-quality gaskets contribute to energy efficiency and reduced fluid consumption.

- Corrosion Resistance: Advanced materials offer excellent resistance to degradation from oil additives, coolants, and environmental factors, extending equipment life.

Technical Specifications of a High-Quality Oil Cooler Gasket

The performance of an Oil Cooler Gasket is defined by a precise set of technical parameters. These specifications ensure the gasket can reliably perform its sealing function under the dynamic and challenging conditions of an engine or industrial system.

Typical Product Specification Table (Example for Oil Cooler Gasket 11427525335):

| Parameter | Specification | Standard/Test Method |

|---|---|---|

| Material Composition | HNBR / FKM Composite | ASTM D2000 Classification |

| Temperature Range | -40°C to +150°C (continuous) | ISO 188 / ASTM D573 |

| Shore Hardness (A) | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 200% | ASTM D412 |

| Compression Set (22h @ 125°C) | ≤ 20% | ASTM D395 Method B |

| Oil Resistance (IRHD, Volume Swell) | Excellent, < +5% in IRM 903 Oil | ASTM D471 |

| Chemical Compatibility | Engine oils, coolants, fuels, some solvents | OEM Specific / ISO 1817 |

| Part Number Compatibility | Replaces OEM # 11427525335 | Cross-Reference Validation |

These specifications underline the necessity of precision engineering and material science in producing a reliable Oil Cooler Gasket, capable of maintaining seal integrity across a broad spectrum of operational demands.

Diverse Application Scenarios

The functionality of an Oil Cooler Gasket extends across a vast array of machinery and industries, underscoring its universal importance. Its primary function is to seal the interface between the oil cooler and the engine block or filter housing, preventing the mixing of oil and coolant and ensuring proper oil pressure.

- Automotive Sector: Essential in passenger cars, light commercial vehicles, and heavy-duty trucks. The gasket ensures the integrity of the oil cooling system, preventing costly engine damage due due to overheating or fluid contamination. Applications include sealing the Oil Cooler to Oil Filter Housing 11427525335 in specific European vehicles.

- Construction & Agricultural Equipment: Used in diesel engines of excavators, bulldozers, tractors, and combines, where they endure extreme vibrations, dust, and temperature fluctuations.

- Marine Engines: Critical for reliable operation in saltwater environments, where corrosion resistance is paramount, and consistent engine performance is vital for safety and efficiency.

- Industrial Power Generation: Ensuring continuous operation of generators and power units, where unexpected downtime can lead to significant financial losses.

- Mining Machinery: Operating under severe mechanical stress and abrasive conditions, these gaskets maintain seals in engines and hydraulic systems of large mining vehicles.

In each of these scenarios, the gasket's ability to maintain a leak-proof seal under fluctuating temperatures, pressures, and exposure to various fluids is non-negotiable for operational reliability.

Key Technical Advantages of Advanced Oil Cooler Gaskets

Investing in a high-quality Oil Cooler Gasket brings a multitude of technical advantages that directly impact the performance, longevity, and cost-efficiency of machinery.

- Superior Sealing Integrity: Precision manufacturing and advanced materials ensure a complete and lasting seal, preventing oil and coolant mixing, which can lead to catastrophic engine failure. This directly translates to improved reliability and reduced maintenance frequency.

- Extreme Temperature Resistance: Designed to withstand the thermal cycles and high operating temperatures inherent in engines, preventing material degradation and loss of sealing force over time. This is particularly crucial for maintaining the seal of components like the Oil Cooler to Oil Filter Housing 11427525335.

- Chemical Compatibility: Resistant to degradation from various engine oils, coolants, fuel additives, and exhaust gases, ensuring the gasket's structural and chemical integrity.

- Extended Service Life: High-grade materials and robust construction lead to a significantly longer operational lifespan, reducing the need for frequent replacements and associated labor costs.

- Vibration and Pressure Resilience: Engineered to withstand dynamic stresses, vibrations, and fluctuating pressures without compromising the seal, critical in high-performance or heavy-duty applications.

- Corrosion Resistance: Specially selected materials provide excellent resistance against rust and chemical corrosion, prolonging the life of both the gasket and the mating components.

- Optimized Engine Efficiency: By preventing leaks and maintaining proper oil circulation, these gaskets help ensure the engine operates at its optimal temperature, contributing to fuel efficiency and reduced emissions.

Advanced materials ensure superior performance and longevity for oil cooler gaskets.

These advantages collectively translate into lower total cost of ownership, enhanced operational safety, and increased environmental compliance for various industrial and automotive applications.

Vendor Comparison and Selection Criteria

Choosing the right supplier for an Oil Cooler Gasket is as critical as the product itself. B2B purchasers must evaluate potential vendors based on a comprehensive set of criteria that go beyond mere price.

Key Factors for Vendor Evaluation:

- Material Quality & Sourcing: Verify that vendors use certified, high-grade raw materials (e.g., specific grades of HNBR, FKM) from reputable sources. Inquire about their material testing protocols.

- Manufacturing Precision & Technology: Assess the supplier's manufacturing capabilities, including their use of advanced molding or die-cutting machinery, and their adherence to tight tolerances.

- Quality Assurance & Certifications: Look for ISO 9001 certification, evidence of stringent in-house quality control, and compliance with industry-specific standards (e.g., IATF 16949 for automotive components). Request test reports for relevant parameters (e.g., temperature resistance, oil swell).

- Technical Expertise & Support: A strong vendor offers robust technical assistance, including material selection guidance, design optimization, and troubleshooting support. This is particularly valuable for specialized components like the Oil Cooler to Oil Filter Housing 11427525335 gasket.

- Customization Capabilities: Evaluate their ability to provide bespoke sealing solutions for unique applications, including rapid prototyping and material adaptation.

- Lead Times & Logistics: Reliable fulfillment, competitive lead times, and efficient global logistics are essential for managing supply chains effectively.

- Reputation & Client References: Investigate the vendor's track record, years of industry service, and seek references or case studies from existing clients to validate their claims of reliability and performance.

- Warranty & After-Sales Service: Understand their warranty policies and the level of post-purchase support offered.

A thorough vendor comparison based on these factors ensures a long-term, reliable partnership and access to superior sealing solutions.

Customized Sealing Solutions

While standard Oil Cooler Gasket solutions meet many requirements, specific applications often demand tailored approaches. Leading manufacturers offer comprehensive customization services to address unique design challenges, material compatibility issues, or extreme operational environments.

Elements of Customization:

- Material Selection: Engineering teams collaborate to specify the optimal elastomer or composite material based on fluid exposure, temperature range, pressure, and chemical compatibility. This can range from highly specialized fluorocarbons for aggressive fuels to unique HNBR compounds for high-temperature oil applications.

- Design Optimization: Adjusting gasket geometry, thickness, bead profiles, or integrating specific features (e.g., reinforcement layers, localized hardness variations) to enhance sealing performance in specific housing designs. This is crucial for precise fitment in components like the Oil Cooler to Oil Filter Housing 11427525335.

- Prototyping & Testing: Offering rapid prototyping services to create functional samples, followed by extensive testing under simulated real-world conditions to validate the custom design before full-scale production.

- Application-Specific Coatings: Applying specialized surface treatments or coatings to enhance friction reduction, chemical resistance, or to improve assembly processes.

Customized solutions ensure that even the most demanding applications receive a sealing component perfectly matched to their requirements, maximizing performance and longevity.

Application Case Studies: Real-World Impact

The efficacy of a robust Oil Cooler Gasket is best illustrated through its performance in real-world scenarios, preventing costly failures and ensuring sustained operational integrity.

Case Study 1: Heavy-Duty Diesel Engine Longevity

A leading manufacturer of heavy-duty diesel engines for commercial trucks faced recurring issues with premature oil cooler gasket failures, leading to coolant-oil mixing and engine damage. The OEM replaced their standard gaskets with an advanced HNBR Oil Cooler Gasket, specifically engineered for higher thermal stability and enhanced resistance to modern engine oils and aggressive coolants. After implementing the new gasket (compatible with the Oil Cooler to Oil Filter Housing 11427525335 specification), field data over 250,000 miles demonstrated a 70% reduction in gasket-related failures. This resulted in significant cost savings from reduced warranty claims, fewer engine repairs, and improved customer satisfaction.

Case Study 2: Industrial Hydraulic System Efficiency

An industrial client operating large hydraulic presses experienced intermittent pressure drops and increased oil consumption due to micro-leaks in their oil cooler assemblies. The existing seals were failing under continuous high-pressure cycles and elevated temperatures. By upgrading to custom-designed FKM oil cooler gaskets, the client observed an immediate cessation of leaks. The superior compression set resistance and high-temperature performance of the FKM material ensured a stable, long-term seal. This improvement led to a 15% reduction in hydraulic fluid top-ups and eliminated unplanned downtime, boosting overall system efficiency and reducing operational expenditure.

Reliable sealing components prevent costly operational failures.

These cases underscore how strategic material selection and precision engineering in Oil Cooler Gasket design directly translate into tangible benefits for industrial and automotive applications.

Frequently Asked Questions (FAQ)

- Q1: What are the primary signs of a failing Oil Cooler Gasket?

- A1: Common indicators include visible oil leaks around the oil cooler or filter housing, presence of oil in the coolant (milky residue in the coolant reservoir), or presence of coolant in the oil (sludgy oil on the dipstick or oil filler cap). Decreased engine oil pressure can also be a symptom.

- Q2: How does material choice impact the lifespan of an Oil Cooler Gasket?

- A2: Material choice is paramount. For instance, HNBR offers superior high-temperature and oil resistance compared to standard NBR, extending service life in demanding engine environments. FKM provides even greater chemical and thermal resistance for extreme applications. Matching the material to the specific operating conditions (temperatures, fluids, pressures) directly dictates the gasket's longevity and reliability.

- Q3: Is professional installation required for an Oil Cooler to Oil Filter Housing 11427525335 gasket?

- A3: Yes, professional installation is strongly recommended. Proper torque specifications, surface preparation, and correct component alignment are crucial for ensuring a leak-free seal and avoiding premature failure. Incorrect installation can lead to immediate or latent leaks.

- Q4: What are the main benefits of using an OEM-specified or equivalent quality Oil Cooler Gasket?

- A4: Using a gasket that meets or exceeds OEM specifications ensures precise fitment, correct material composition, and validated performance under intended operating conditions. This minimizes the risk of leaks, extends component lifespan, and maintains the overall integrity and efficiency of the engine or system.

Lead Time, Warranty, and Customer Support

Understanding the logistical and support frameworks of a sealing solutions provider is essential for B2B procurement and long-term operational planning.

Lead Time and Fulfillment:

Typical lead times for standard Oil Cooler Gasket products range from 2-4 weeks, depending on order volume and material availability. For customized solutions, lead times may vary from 6-10 weeks, incorporating design, prototyping, and testing phases. We maintain robust inventory management and flexible manufacturing capabilities to meet urgent requirements and support just-in-time (JIT) deliveries for key clients.

Warranty Commitments:

Our high-quality oil cooler gaskets are backed by a comprehensive 12-month or 20,000-mile warranty (whichever comes first), covering defects in material and workmanship under normal operating conditions. This commitment reflects our confidence in the durability and performance of our products, including the Oil Cooler to Oil Filter Housing 11427525335 gasket.

Dedicated Customer Support:

We offer dedicated technical support and after-sales service, accessible through multiple channels including phone, email, and a dedicated online portal. Our team of experienced engineers and product specialists is available to assist with product selection, installation guidance, troubleshooting, and any post-purchase inquiries, ensuring optimal product utilization and customer satisfaction.

Conclusion

The Oil Cooler Gasket is far more than a simple sealing component; it is a critical engineering element vital for the operational integrity, efficiency, and longevity of engines and industrial machinery. As technology advances, the demands on these gaskets increase, necessitating continuous innovation in material science and manufacturing precision. By prioritizing high-quality materials, rigorous testing, and adherence to international standards, manufacturers can deliver sealing solutions that not only prevent costly leaks but also contribute significantly to the overall performance and reliability of complex systems. For B2B stakeholders, understanding these nuances is crucial for making informed procurement decisions that translate into long-term operational benefits and sustained profitability.

References

- ASTM International. (n.d.). _ASTM Standards for Rubber and Rubber Products_. Retrieved from astm.org

- ISO. (n.d.). _ISO 9001 - Quality management systems_. Retrieved from iso.org

- SAE International. (n.d.). _SAE J200 - Classification System for Rubber Materials for Automotive Applications_. Retrieved from sae.org

- Freudenberg Sealing Technologies. (n.d.). _Material Guide_. Retrieved from freudenberg-group.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories