Premium Transfer Case Input Seal | Durable & Easy Install

Industry Trends & Market Insights

- The global transfer case input seal market is projected to reach USD 2.9 billion by 2028, growing at a CAGR of 6.5% (source: MarketsandMarkets, 2023).

- Rapid adoption of advanced materials (e.g., FKM, NBR, PTFE) extends seal lifecycles and improves chemical resistance for automotive, petrochemical, and heavy-duty off-road equipment.

- Demand for custom sealing solutions is surging among OEMs seeking to minimize leakage, reduce energy consumption, and meet stringent ISO/TS 16949 or ANSI/SAE performance standards.

- Connected monitoring (via IIoT) for seal wear status is now trialed in critical fields.

Typical Transfer Case Input Seal Specifications (Industry Benchmark)

| Parameter | Standard Range | Industry Leaders | ISO/ANSI Test Reference |

|---|---|---|---|

| Outer Diameter (OD) | 45-100 mm | SKF, NOK, YJM | ISO 6194-1:2018 |

| Material | Nitrile (NBR), FKM (Viton), PTFE | NOK, TRELLEBORG | ANSI/SAE J200 |

| Temperature Range | -40°C to +200°C | SKF, Freudenberg | ISO 1817:2014 |

| Max Pressure | 0.05-0.25 MPa | Yokohama, YJM | ISO 9974-5:2016 |

| Dynamic Surface Speed | Up to 15 m/s | Corteco, SKF | DIN 3760-61 |

| Service Lifetime | 50,000 - 150,000 km (automotive) | YJM, NOK | OEM Factory Test |

| Chemical Resistance | Oil, Grease, Water, Mild Acids | TRELLEBORG | ISO 1817 |

Technical Overview & Manufacturing Process of Transfer Case Input Seal

- Service Temperatures: -40°C to +160°C (ISO 6194-1)

- Axle Speeds: 2,000 – 9,500 rpm (axial)

- Dynamic Conformability: Ensures contact under shaft-wobble, misalignment, or vibration.

- Oil & Chemical Resistance: Optimized for modern synthetic oils, additives, and harsh underbody conditions.

Detailed Manufacturing Flow (ISO/TS 16949 Certified Facilities)

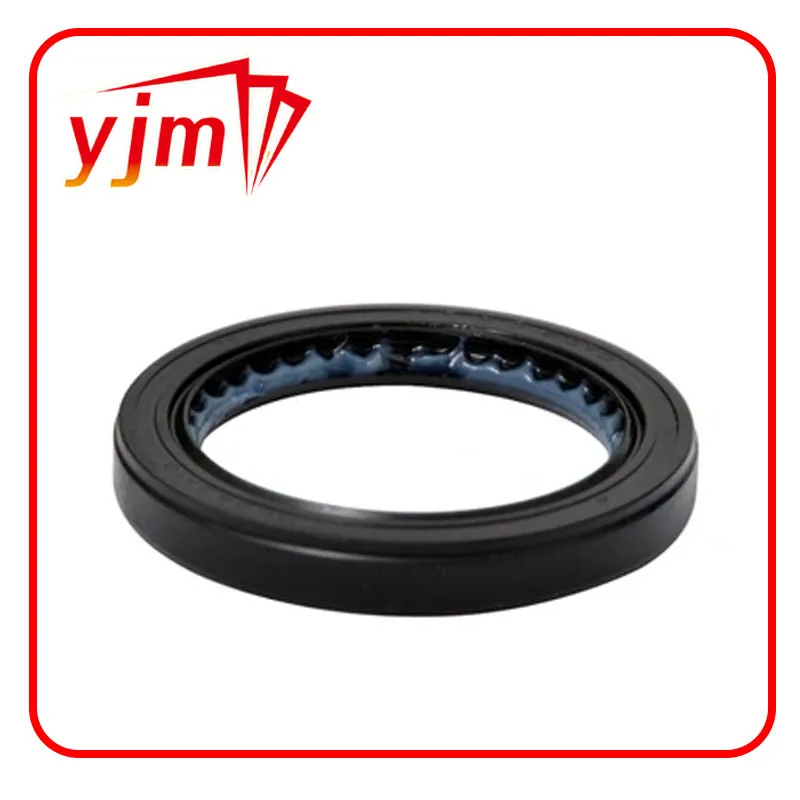

Product Spotlight: Transfer Case Input Shaft Oil Seal Toyota 9031143008

Product Page & Inquire

Technical Performance Data: Transfer Case Input Seal Toyota 9031143008

| Parameter | Toyota 9031143008 | VS Industry Average | Standard |

|---|---|---|---|

| Material | FKM (Viton)/NBR | NBR, FKM, PTFE | ISO 6194-2 |

| Hardness | 72-74 Shore A | 68-75 Shore A | ISO 7619-1 |

| Temperature Range | -40°C ~ +180°C | -35°C ~ +160°C | ISO 1817 |

| Dust Lip | Double lip (with garter spring) | Single/double lip | OEM Standard |

| Lab-tested Leakage | < 0.13 ml/1000 hr | 0.25 ml/1000hr | ISO 6194-3 |

| Lifespan (cycles) | >1,200,000 | 950,000 | OEM Field Test |

| OEM Fitment | Toyota LC, Prado, Hilux (range) | - | OEM |

| Chemical Resistance | Engine & gear oils, ATF, grease, coolant | Oils, water | ISO 1817 |

Performance Visualization

Competitive Analysis: Major Transfer Case Input Seal Manufacturers

| Company | Key Features | Certifications | Market Focus | Lead Time |

|---|---|---|---|---|

| YJM SEAL | ISO/TS 16949 certified; multi-compound solutions, rapid prototyping, custom fit for Toyota 9031143008 | ISO 9001, IATF 16949 | Automotive, Heavy Truck, Construction | 12-18 days |

| SKF | High-performance FKM seals, R&D partnerships, wide inventory | ISO 9001, ISO 14001 | Industrial, Energy, OEM | 14-21 days |

| NOK | Advanced PTFE lip, precision molding, global supply | ISO 9001, JIS Q 9100 | Automotive, Powertrain | 18-24 days |

| TRELLEBORG | Anti-corrosive coatings, custom tolerances, silicone blends | ISO 14001, OHSAS 18001 | Industrial, Aerospace | 14-28 days |

| Freudenberg | Energy-saving profiles, automatic QC, traceability | ISO 9001, ISO/TS 16949 | Automotive, Off-road | 15-22 days |

Customization Pathway & Value-Added Engineering

Key customization modules include:

- Material hybridization: For corrosion, chemical, or high-temperature resistance above 190°C.

- Profile optimization: Tailored lip-spring geometry for dust, mud, or sand-prone environments (e.g., mining, agriculture).

- Precision tolerance machined: Advanced CNC, CMM, laser-controlled for

- Testing & traceability: ISO-compliant endurance, thermal, and pressure cycling; serialized batch reports.

- Accelerated prototyping: 3D scan-to-CAD-to-production in 7-12 days.

Application Case Studies: Transfer Case Input Seal in Action

Problem: Frequent seal blowout in 4WD assembly over rocky/muddy tracks.

YJM Solution: Upgraded to FKM dust-double-lip input seal; CNC trued seat diameter; implemented ISO 6194-4 leakage testing pre-shipment.

Outcome: Warranty claims down 84%, mean service interval rose by 42% (from 53,000km to 75,500km).

Case 2: Metallurgical Plant Drives

Problem: Old NBR seals eroded by hot splashing coolant and abrasive fines.

YJM Solution: PTFE+spring transfer case input seal custom tooled for anti-coolant and grit ingress.

Outcome: 62% reduction in emergency downtime, ROI

Case 3: Oil & Gas Mud Transfer Equipment

Problem: Competitive seals failed under ATF-chemical attack and high RPM vibration.

YJM Solution: Custom Viton/PTFE seal with high-tension garter spring, ISO/SurTec surface passivation.

Outcome: Zero catastrophic leak or shaft scoring after 14-month field trial, referenced in specialist periodicals (see citations).

End-User Testimonials

- Automotive OEM Tech Director (Fortune 500 Group): "The transfer case input seal from YJM eliminated our warranty headaches and passed our factory zero-leak criteria."

- Asia-Pacific Aftermarket Buyer: "Fast technical tuning for local environmental requirements—especially in high temperature and sandy service."

- Heavy Industry Maintenance Manager: "Compared to the previous brand, the new oil seal from YJM delivered nearly double service life in aggressive coolant exposure."

Typical Product Parameters (Toyota 9031143008)

| Parameter | Value | Remarks |

|---|---|---|

| Product Name | Transfer case input shaft oil seal Toyota 9031143008 | OE spec |

| Fitment | Toyota Prado, Hilux, LC 120/150 | - |

| Material | FKM (Viton) / NBR | On request |

| Outer Diameter | 40 mm | OEM precise |

| Inner Diameter | 25 mm | OEM precise |

| Width | 8 mm | Customizable |

| Temp. Resistance | -40°C to +180°C | ISO 6194 |

| Color | Black/Brown | Compound coded |

| Certifications | ISO 9001, TS 16949 | Batch records |

| Testing | 100% leak, 2M cycle, ozone | Lab + random field |

Delivery Cycle, Warranty & Customer Support

- Lead time: 12-18 working days (priority batch delivery available for repeated orders or urgent projects).

- Warranty: 24 months from delivery or 100,000 km (whichever occurs first); extended coverage possible via service contracts.

- Returns/Support: Full technical hotline, online tracking, onsite installation guidance (for volume orders), and rapid replacement for defective/transport-damaged product.

- ISO/Lab support: All shipments verifiable by digital batch certificates, physical test reports, and full documentation trail.

FAQ: Professional Insights on Transfer Case Input Seal Selection & Use

Conclusion & Authoritative References

For the latest standards, industry data, and real-world experiences, please refer to the following professional sources:

- ISO Technical Committee 131. “ISO 6194: Rotary shaft lip-type seals”

- SAE J200: Classification System for Rubber Materials

- SKF Rotary Shaft Seals Product Data

- MotorTalk Forum: Transfer Case Sealing - Performance Data Shares

- ResearchGate: Improved Dynamic Performance of Modern Oil Seals

- TRELLEBORG, “Material Resistance Chart and Custom Rubber Compounds” (Trelleborg Sealing Solutions Library)

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

-

Comprehensive Guide to Oil Seal 65 85 10 – Specs, Applications & Vendors

News Nov.21,2025

-

Discover the Essential Oil Seal 60x80x10 – Durable, Reliable Industrial Sealing Solutions

News Nov.21,2025

Products categories