Oil Pan Gasket That Stops Leaks Fast—Why Choose Ours?

oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan is a key solution in the automotive industry, specifically within auto parts and Engine Parts. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan Overview

- Benefits & Use Cases of oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan in Engine Parts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan from JULU YJM HWMF SEAL CO.,LTD.

oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan Overview

An oil pan gasket—also called a pan gasket or engine sump gasket—is the sealing interface between the oil pan and the crankcase, preventing engine oil leaks under thermal cycling, vibration, and crankcase pressure pulses. In the automotive industry → auto parts → Engine Parts value chain, it is a small component with outsized impact on reliability, warranty exposure, and workshop efficiency. Depending on engine design, gaskets may be molded elastomer on a steel carrier (commonly NBR, ACM, FKM, or VMQ silicone), fiber-reinforced materials, or a formed-in-place solution using a liquid gasket for oil pan applications (RTV/FIPG) where complex flange geometries demand it.

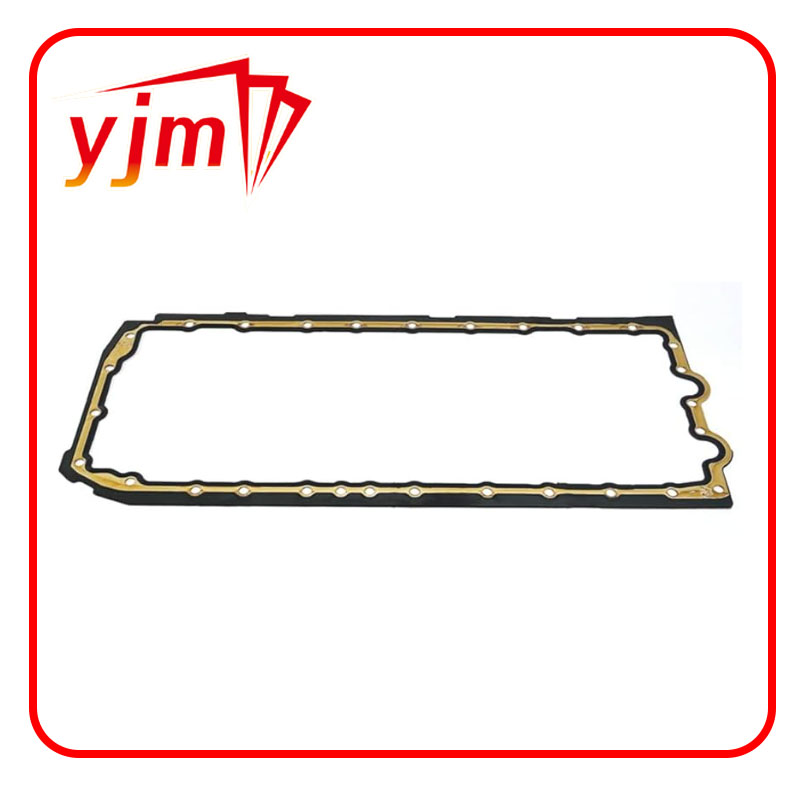

JULU YJM HWMF SEAL CO.,LTD. manufactures automotive-grade gaskets with precise flange conformity, continuous sealing beads, and chemical resistance to modern low-viscosity oils and additives. For reference, our product range includes applications such as the BMW oil sump gasket (part ref. 11137548031) detailed here: product page. Engineered for consistent compressibility and low relaxation, our pan gaskets are designed to support both OEM and aftermarket requirements where dimension stability, clean assembly, and durable sealing are critical.

Benefits & Use Cases of oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan in Engine Parts

Across passenger vehicles, light commercial fleets, and performance applications, the oil pan gasket must seal reliably despite flange distortion, bolt load variation, and oil splash. JULU YJM HWMF SEAL CO.,LTD. offers molded rubber-on-carrier pan gaskets for fast, clean installation, as well as guidance for using a liquid gasket for oil pan designs where an FIPG/RTV bead is the specified solution. Typical use cases include engine assembly lines, scheduled overhauls, and aftermarket service where downtime and rework are costly.

Key advantages include dimensional accuracy for a proper fit, engineered bead geometry to counter micro-movement, and elastomer formulations tailored for heat, oil, and fuel dilution resistance. Optional anti-stick surfaces help ensure easy removal during future servicing. For customers consolidating SKUs, our engineering team can assist with material selection and design optimization to meet target torque retention and sealing performance. Backed by robust process control and traceable batches, JULU YJM HWMF SEAL CO.,LTD. helps B2B decision makers standardize quality across multiple platforms while reducing leak-related comebacks.

Cost, Maintenance & User Experience

Total cost of ownership for a pan gasket or engine sump gasket is measured by leak prevention, installation speed, and resilience across service intervals. A properly specified oil pan gasket lowers rework, eliminates oil drip claims, and reduces cleanup materials—directly improving ROI for workshops and fleet operators. Customers report smoother installations thanks to consistent bolt-hole alignment and sealing bead profiles that minimize the need for additional compounds; where specified, a liquid gasket for oil pan sealing can also be deployed with clear cure-time guidance for predictable results.

Best practices for maintenance include thorough flange cleaning, removal of old RTV without scoring, inspection for warpage, and adherence to the OEM torque sequence and values. Avoid over-torquing, which can cause flange pinch or gasket extrusion. Store gaskets flat, away from UV and extreme temperatures to preserve elastomer properties. With these steps, users typically experience reduced bay time, fewer callbacks, and longer service life—key contributors to better margins and customer satisfaction in the auto parts sector.

Sustainability & Market Trends in automotive industry

Leak-free engines support environmental goals by preventing oil contamination of roads and soil, aligning with tightening global regulations on emissions and fluid management. Material innovations—such as low-compression-set elastomers and optimized carrier designs—extend service life, cut waste, and reduce the reliance on excess sealants. Where a liquid gasket for oil pan applications is specified, precise bead control and proper curing help limit material overuse and wipe-off waste, contributing to cleaner, safer workshops.

Market trends show continued demand for high-stability gaskets compatible with low-viscosity oils, turbocharged engine temperatures, and longer oil-change intervals. JULU YJM HWMF SEAL CO.,LTD. is investing in process efficiency, careful material selection, and packaging that reduces waste, helping B2B buyers meet sustainability targets without sacrificing performance. As ICE and hybrid powertrains remain central to many markets, high-quality oil pan gasket solutions will continue to be essential for OEM, OES, and aftermarket channels.

Conclusion on oil pan gasket, pan gasket, engine sump gasket, liquid gasket for oil pan from JULU YJM HWMF SEAL CO.,LTD.

From OEM programs to aftermarket service kits, a dependable oil pan gasket safeguards engines, protects margins, and supports sustainability goals. JULU YJM HWMF SEAL CO.,LTD. delivers engineered pan gasket and engine sump gasket solutions—along with expert guidance on when and how to use a liquid gasket for oil pan applications—to help B2B teams cut leak-related costs and standardize quality across platforms. For specifications, samples, or sourcing support: Contact us: email: yjm006@hwmf.com. Visit our website: https://www.yjmseal.com.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories