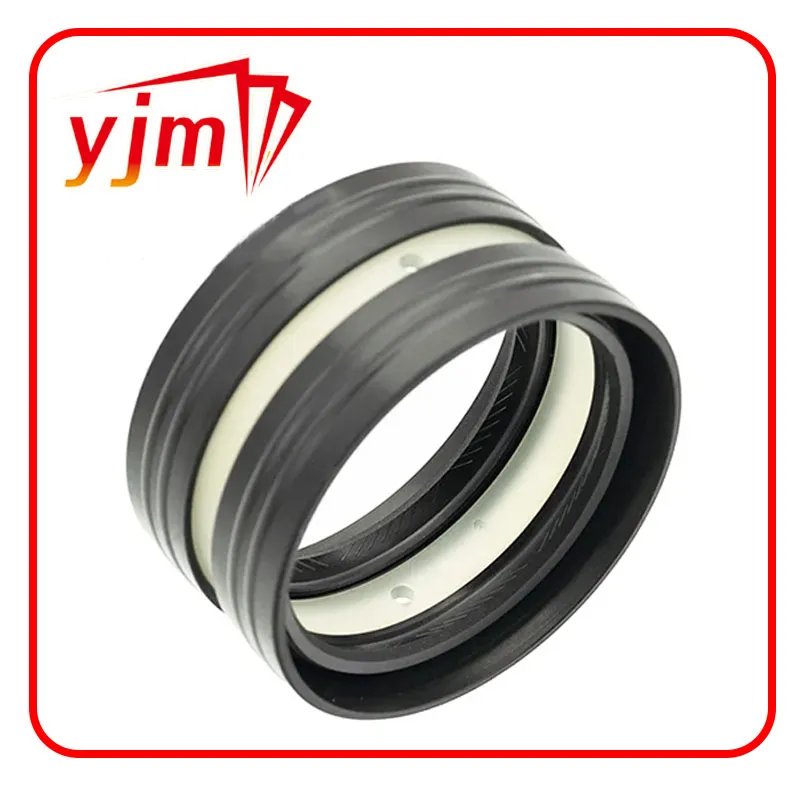

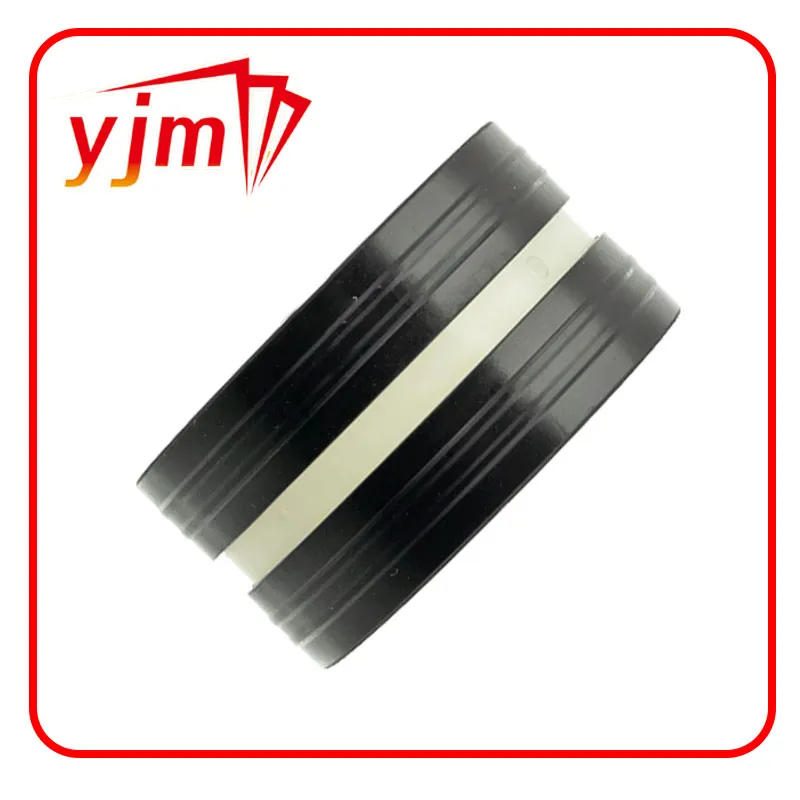

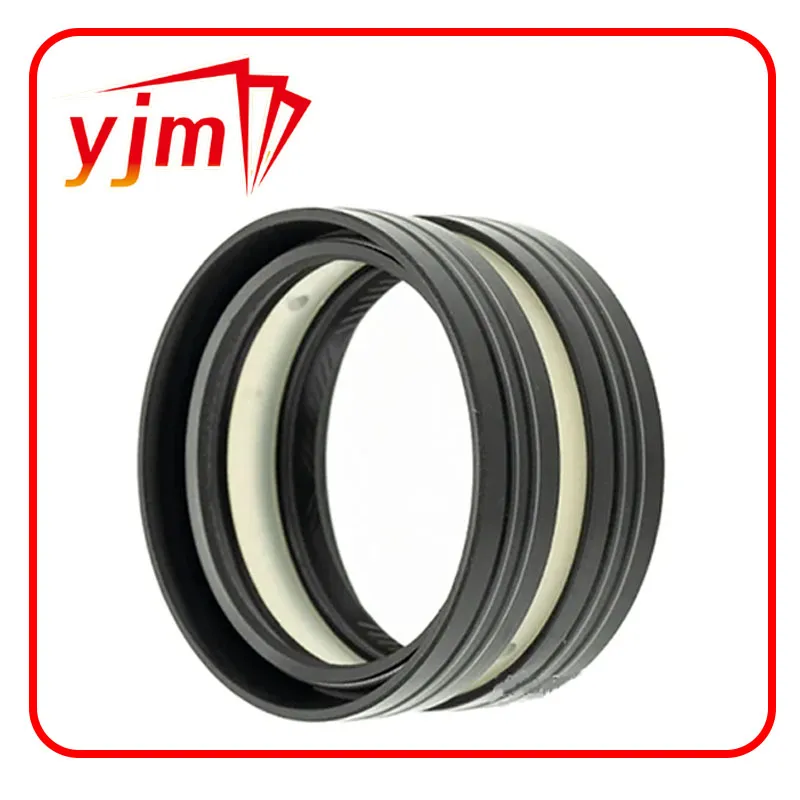

Seal for TOYOTA 9031634001, Type D Oil | Leak-Proof OEM Fit

Field Notes on the Seal Type D Oil 90316-34001 for Toyota

I’ve spent a chunk of my career around drivetrains and rotating equipment, and—believe it or not—the smallest component often decides the biggest repair bill. The Seal we’re talking about here is the Type D Oil 90316-34001, a Genuine New Part for Toyota. It’s manufactured in JULU INDUSTRY AREA, XINGTAI CITY, HEBEI PROVINCE, CHINA 055250. Many customers say it’s the “fit-and-forget” piece they wish they’d used first.

Quick product brief

- Manufacturer: TOYOTA (Genuine New Part)

- Part number: 90316-34001 (SEAL, TYPE D OIL)

- Country of origin: China

- Condition: Genuine new, not remanufactured

Industry trends (why this matters now)

Two clear shifts: extended service intervals and tighter emission/efficiency targets. In practice, that puts more heat and longer duty cycles on rotary lip components. The result? Demand for higher-grade elastomers, better spring loads, and stricter runout/tolerance control. The Seal Type D—with a dual-lip architecture—suits that trend well.

Technical specifications (typical)

| Lip design | Type D (dual-lip with garter spring) |

| Material | NBR or FKM depending on batch/application (≈70–80 Shore A) |

| Temp range | ≈ -30°C to +120°C (NBR) / up to ≈ +200°C (FKM); real-world use may vary |

| Media compatibility | Engine oil, ATF, gear oil (per ISO 1817 guidance) |

| Dimensions | ID ≈ 34 mm (ref. PN), OD/width per OEM drawing; verify before ordering |

| Standards | Designed to ISO 6194 / DIN 3760 principles; elastomer per ASTM D2000 |

Process flow and quality

Materials are selected (NBR/FKM) against the oil chemistry. Compounds are mixed and molded, then vulcanized. The garter spring is installed, lips are precision trimmed, and surfaces receive anti-corrosion oil. Each batch typically undergoes leakage testing (ISO 6194), compression set checks (ASTM D395), and dimensional inspection. Service life in mixed fleet use is often 80–120k km, though driving style and shaft condition dictate the upper bound.

Applications and advantages

- Use cases: Toyota engines, transmissions, and differentials requiring 90316-34001.

- Industries: passenger vehicles, light commercial fleets, aftermarket service centers.

- Advantages: strong lip stability at speed, good oil retention, and reduced weeping after heat soak.

Vendor comparison (observed in the field)

| Vendor | Material grade | Tolerance control | Certifications | Warranty |

| Genuine Toyota 90316-34001 (this Seal) | NBR/FKM, OEM grade | Tight; OEM process capability | ISO 9001 / IATF 16949 (typical for OEM supply) | OEM channel warranty |

| Aftermarket (quality brand) | Automotive grade NBR | Good, varies by batch | ISO 9001; some IATF | Limited |

| Low-cost import | Basic NBR | Inconsistent | Varies | Minimal |

Customization and support

For special duty—higher temps, bio-based oils, or unusual shaft finishes—specifying FKM, a dust lip, or micro-spring variant helps. Lead time and MOQ depend on tooling. To be honest, most shops don’t need custom: the OEM Seal fits right and lasts.

Case study (fleet anecdote)

A regional delivery fleet saw recurring weeps on a pair of vehicles using budget parts. Switching to this Genuine Seal during scheduled services cut subsequent oil-top-ups to zero over 12 months, with no visible leakage post 25,000 km checks. Not a lab result—just practical data from their maintenance logs.

Testing and compliance

- Leakage/runout and endurance guided by ISO 6194 and DIN 3760.

- Elastomer classification per ASTM D2000; compression set per ASTM D395.

- Typical automotive QMS: ISO 9001 / IATF 16949 credentials at the plant level.

Citations

- ISO 6194 (Rotary shaft lip-type seals) – Overview and test methods. https://www.iso.org/standard/

- DIN 3760: Rotary shaft lip seals – DIN Standards summary. https://www.din.de

- ASTM D2000 & D395 – Rubber materials classification and compression set. https://www.astm.org

- IATF 16949: Automotive QMS requirements. https://www.iatfglobaloversight.org

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories