wall oil seal

The Importance of Wall Oil Seals in Industrial Applications

In various industrial applications, the importance of efficiently sealing against oil leakage cannot be understated. One critical component in achieving this is the wall oil seal, an integral part of machines that helps maintain operational efficiency and prevent potential damages. This article delves into the significance, functionality, and applications of wall oil seals in different sectors.

What is a Wall Oil Seal?

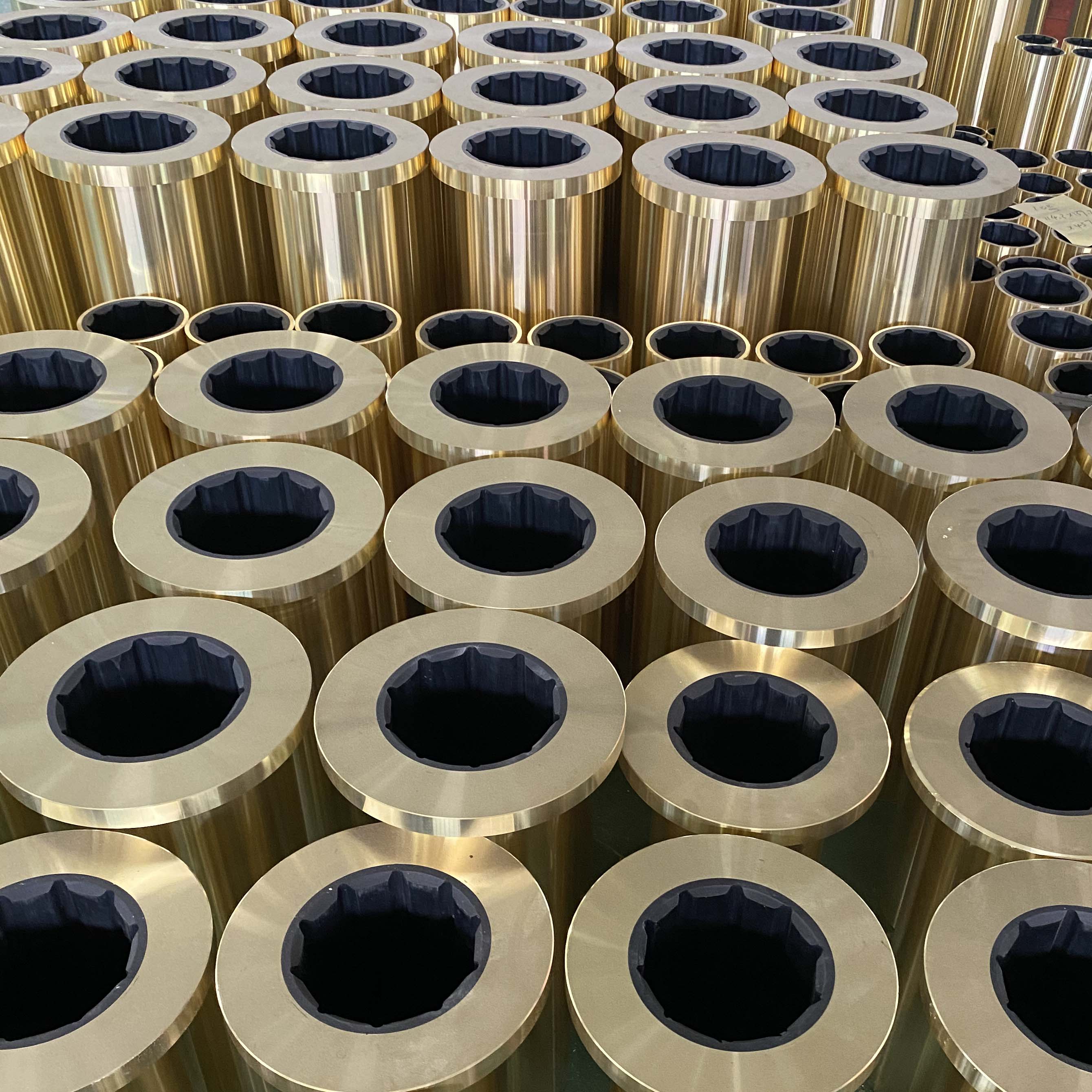

A wall oil seal is a type of mechanical seal designed to prevent the escape of lubricating oils and other fluids in machinery. Typically made from materials like rubber, polyurethane, or special polymers, these seals are engineered to provide a tight barrier against leakage. They are often used in conjunction with rotating shafts or stationary components, effectively minimizing the loss of lubricant and protecting the internal parts of machines from contamination.

Functionality of Wall Oil Seals

The primary role of a wall oil seal is to ensure that lubricating oil stays contained within a system, thus preventing it from leaking out. This is particularly crucial in machinery where oil plays a vital role in reducing friction, cooling components, and maintaining overall performance. A well-functioning oil seal helps minimize wear and tear on moving parts, ultimately extending the lifespan of machinery.

Wall oil seals operate by forming a contact with the rotating shaft or wall, creating a flexible barrier

. The design often includes features like a spring mechanism that applies consistent pressure, ensuring that the seal maintains its position, even under varying operational conditions. Additionally, wall oil seals can accommodate minor misalignments and eccentric movements, making them ideal for dynamic applications.Applications of Wall Oil Seals

Wall oil seals are widely used in various industries, including automotive, aerospace, manufacturing, and construction. In automotive applications, these seals are critical in engine assemblies, transmission systems, and differential housings. They prevent oil leaks that could lead to engine failure or reduced performance while also keeping harmful contaminants out of the lubricating system.

wall oil seal

In the industrial sector, wall oil seals are essential in machinery such as pumps, compressors, and gearboxes. With the growing trend toward automation and advanced manufacturing processes, the demand for reliable sealing solutions has surged. Oil seals protect sensitive components from dust, dirt, and moisture, thereby ensuring smooth operations and reducing maintenance costs.

Moreover, wall oil seals are also vital in the aerospace industry. Aircraft engines and systems require highly reliable sealing solutions to function optimally under extreme conditions. The failure of a wall oil seal in this context could lead to catastrophic results, making quality control and regular inspections paramount.

Benefits of Using Quality Wall Oil Seals

1. Reduction of Downtime Efficient sealing minimizes oil leakage, leading to increased machinery uptime. This is critical for industries where operational efficiency directly translates to profitability.

2. Cost Effectiveness Preventing oil leaks reduces replenishment needs and maintenance interventions, which can save companies significant amounts of money over time.

3. Enhanced Performance With effective sealing, machinery can operate with optimal lubrication, leading to better performance and longevity of components.

4. Environmental Protection By minimizing oil spills and leaks, wall oil seals help companies adhere to environmental regulations and reduce their ecological footprint.

Conclusion

Wall oil seals play a critical role in various industrial applications, providing essential benefits that enhance the efficiency and reliability of machinery. As technology evolves and machinery designs become more sophisticated, the importance of high-quality sealing solutions, including wall oil seals, will continue to grow. Industries must prioritize the selection and maintenance of these seals to ensure operational excellence, cost efficiency, and environmental responsibility. Understanding the intricacies of wall oil seals not only aids in better machinery management but also significantly contributes to the sustainability of industrial practices in the modern age.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories