50x90x10 oil seal

Understanding the 50x90x10 Oil Seal Applications and Importance

Oil seals, also known as grease seals or fluid seals, play a critical role in a wide array of machinery and automotive applications. Among the various types and sizes available in the market, the 50x90x10 oil seal stands out for its specific dimensions and capacities. Understanding this type of oil seal's functions, construction, applications, and maintenance requirements is crucial for ensuring the longevity and efficiency of machinery.

Dimensions and Specifications

The designation 50x90x10 refers to the oil seal's measurements a nominal outer diameter of 90 mm, an inner diameter of 50 mm, and a width (or thickness) of 10 mm. The 20 typically signifies additional specifications, such as material characteristics or performance standards. These dimensions indicate that the oil seal is designed for specific applications that require a fit between these two rotating components, effectively preventing the leak of lubricants and ingress of contaminants.

Construction and Materials

Oil seals are generally made from a variety of materials, including rubber, silicone, and sometimes even metal, depending on the application requirements. The composition of the 50x90x10 oil seal often includes elastomers that provide resilience and flexibility while offering excellent resistance to oils, water, and various chemicals. The sealing lip is precisely engineered to create a tight seal against the shaft, ensuring minimal friction and wear over time.

Functions of the Oil Seal

50x90x10 oil seal

The primary function of an oil seal is to contain lubricating oils while preventing any unwanted external contaminants from entering the bearing or gearbox that it protects. This containment is vital in maintaining the efficiency of mechanical systems. By providing a secure barrier, oil seals help enhance the lifespan of machinery components by reducing wear caused by particulate matter or moisture intrusion. Furthermore, they minimize the leakage of lubricants, ensuring optimal performance of hydraulic systems, engines, and gearboxes.

Applications in Industry

The 50x90x10 oil seal finds applications in a myriad of fields, including automotive, industrial machinery, and aerospace. In automotive contexts, it is commonly used in engines, transmission systems, and wheel bearings. For industrial applications, these oil seals can be found in hydraulic cylinders, pumps, reducers, and other machinery where lubrication integrity is critical. The versatility of the 50x90x10 oil seal makes it indispensable in ensuring the smooth operation of various mechanical systems.

Maintenance and Replacement

Regular maintenance is essential for prolonging the life of an oil seal. Signs of wear, such as leakage around the seal or visible cracks in the material, warrant immediate attention. Operating machinery with a faulty oil seal can lead to extensive damage and costly repairs. When replacing an oil seal, it is important to choose the correct size and material compatible with the specific application to maintain optimal functioning.

Conclusion

The 50x90x10 oil seal is a small but essential component that significantly impacts the performance and durability of machinery. Its specific dimensions and robust construction make it suitable for various industrial and automotive applications. Understanding the importance of oil seals, recognizing the signs of wear, and ensuring timely maintenance and replacement is key to maintaining the efficient operation of mechanical systems. As technology advances and machinery demands grow, the role of oil seals will continue to be critical in safeguarding operations and enhancing overall machine performance.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

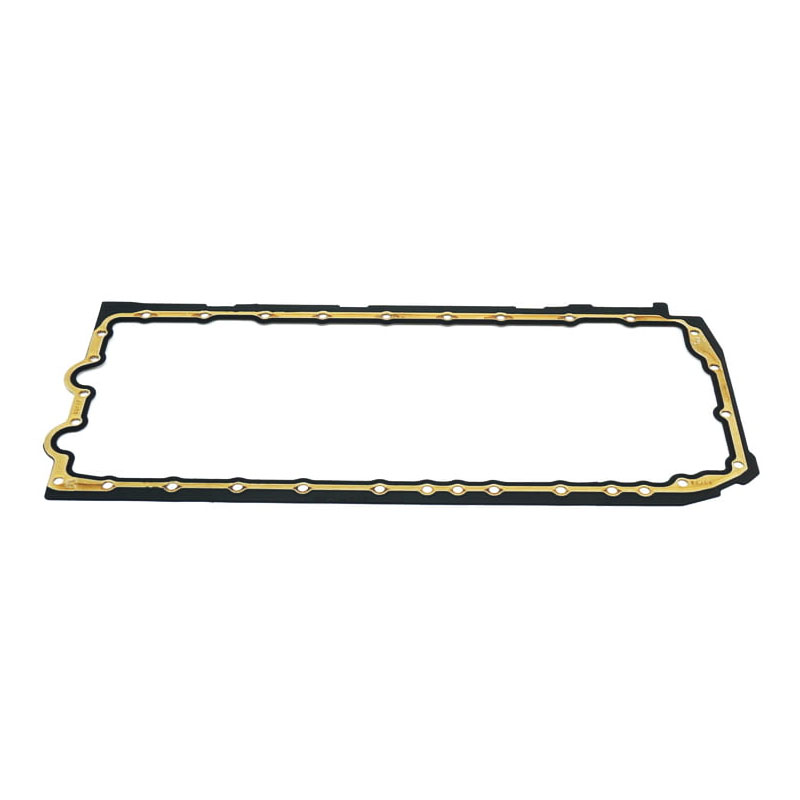

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories