Understanding the Role of Engine Crankshaft Oil Seals in Preventing Engine Damage

Engine crankshaft oil seals are crucial components in a vehicle's engine system, playing a vital role in maintaining engine integrity and performance. These seals prevent oil leaks, protect engine components from contaminants, and ensure the engine operates smoothly. This article explores the fundamental role of crankshaft oil seals, how they prevent engine damage, and why maintaining them is essential for your vehicle’s health.

What Are Engine Crankshaft Oil Seals?

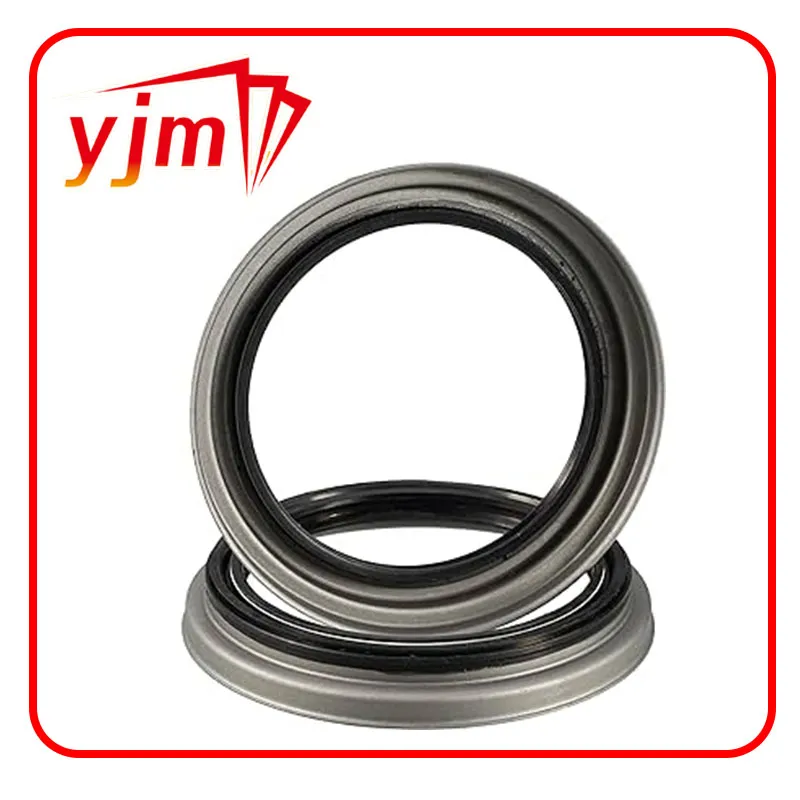

Engine crankshaft oil seals are designed to seal the area where the crankshaft exits the engine block. Positioned at both the front and rear of the crankshaft, these fenner oil seals prevent engine oil from leaking out and keep contaminants from entering the engine. Made from durable materials like rubber or synthetic elastomers, they are engineered to withstand the intense pressure and temperature variations experienced within the engine.

The primary function of these seals is to ensure that the engine’s lubrication system remains contained, preventing any loss of oil that could lead to inadequate lubrication of engine components.

Preventing Oil Leaks and Maintaining Lubrication

One of the most critical roles of flange oil seal is to prevent oil leaks. Engine oil is essential for lubricating the moving parts of the engine, reducing friction, and preventing overheating. If the oil seals fail, oil can leak out, leading to a decrease in lubrication, which in turn can cause increased friction and potential damage to engine components.

When the oil level drops due to leaks, it can lead to severe engine wear and potentially catastrophic engine failure. Therefore, a well-functioning crankshaft oil seal ensures that the engine maintains adequate oil levels, protecting the engine from excessive wear and extending its lifespan.

Protecting Engine Components from Contaminants

In addition to preventing oil leaks, crankshaft oil seals also protect the engine from external contaminants. Dust, dirt, and debris can enter the engine if the seals are compromised, leading to potential damage to internal components. These contaminants can cause abrasions, clog filters, and disrupt the proper functioning of the engine, resulting in costly repairs and reduced engine efficiency.

Crankshaft oil seals act as a barrier, preventing these harmful particles from entering the engine and ensuring that the internal environment remains clean and free of debris. This protection is crucial for maintaining engine performance and reliability over time.

The Impact of Seal Failure on Engine Performance

The failure of a crankshaft oil seal can have significant repercussions on engine performance. When a seal fails, oil leaks can lead to several problems:

Engine Overheating: Without sufficient lubrication, the engine can overheat due to increased friction between moving parts. Overheating can cause serious damage to the engine, including warping of components and potential failure.

Loss of Power: Inadequate lubrication can reduce engine efficiency, leading to a loss of power and performance. The engine may struggle to operate smoothly, resulting in decreased acceleration and overall driving performance.

Increased Wear and Tear: Prolonged exposure to inadequate lubrication accelerates the wear and tear on engine components. This can lead to costly repairs or even the need for a complete engine overhaul.

Signs of Crankshaft Oil Seal Failure

Recognizing the signs of a failing crankshaft oil seal is crucial for preventing further damage to the engine. Common indicators of seal failure include:

Oil Leaks: Visible oil leaks around the crankshaft area or underneath the vehicle are a clear sign that the oil seal may be compromised.

Engine Noise: Unusual noises, such as grinding or whining sounds, can indicate that the engine is experiencing increased friction due to a lack of proper lubrication.

Oil Smoke: Blue or white smoke from the exhaust can indicate that oil is burning due to leaks or internal engine problems.

If any of these symptoms are observed, it is essential to address the issue promptly by inspecting and replacing the crankshaft oil seal if necessary.

Maintaining and Replacing Crankshaft Oil Seals

Regular maintenance and timely replacement of crankshaft oil seals are vital for ensuring engine health and performance. Routine checks should be performed to inspect for signs of oil leaks or other issues. Ensuring that the seals are in good condition can prevent more severe engine problems and extend the life of the vehicle.

When replacing a crankshaft oil seal, it is important to use high-quality seals that match the specifications of the vehicle. Proper installation is also crucial to avoid potential leaks and ensure the seal functions effectively. Consulting a professional mechanic for replacement and maintenance can help ensure that the job is done correctly.

JULU YJM HWMF SEAL-Your Reliable Rubber Seals Manufacturer

Rubber seals play a vital role in industrial fields. Only by purchasing from trustworthy manufacturers can the quality and precision be guaranteed. JULU YJM HWMF SEAL CO., LTD is a leading manufacturer of rubber seals in China, With many years of industry experience and excellent reputation, is able to be come your reliable supplier. Contact us now to get more information.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories