Material Innovations in Front Drive Shaft Oil Seals: What’s New and Why It Matters

Front drive shaft oil seals are critical components in a vehicle’s drivetrain, designed to keep lubricant in and contaminants out of the drive shaft assembly. As automotive technology evolves, so does the need for more advanced materials in these seals. Innovations in material science are significantly enhancing the performance, durability, and reliability of front drive shaft oil seals. This article explores the latest advancements in sealing materials, why they matter, and how they contribute to better vehicle performance.

The Evolution of Sealing Materials About Front Drive Shaft Oil Seals

Historically, high temperature oil seals were made from basic rubber compounds. While effective to a degree, these traditional materials often had limitations regarding durability and resistance to extreme conditions. As vehicles became more advanced, so did the materials used in their components. Modern oil seals now incorporate advanced materials designed to withstand harsher operating environments and provide improved sealing performance.

The evolution of materials used in radial oil seal includes the development of synthetic elastomers and composite materials, each offering distinct advantages over their predecessors. Understanding these innovations helps in appreciating their impact on vehicle maintenance and performance.

Synthetic Elastomers: Enhanced Durability and Flexibility With Front Drive Shaft Oil Seals

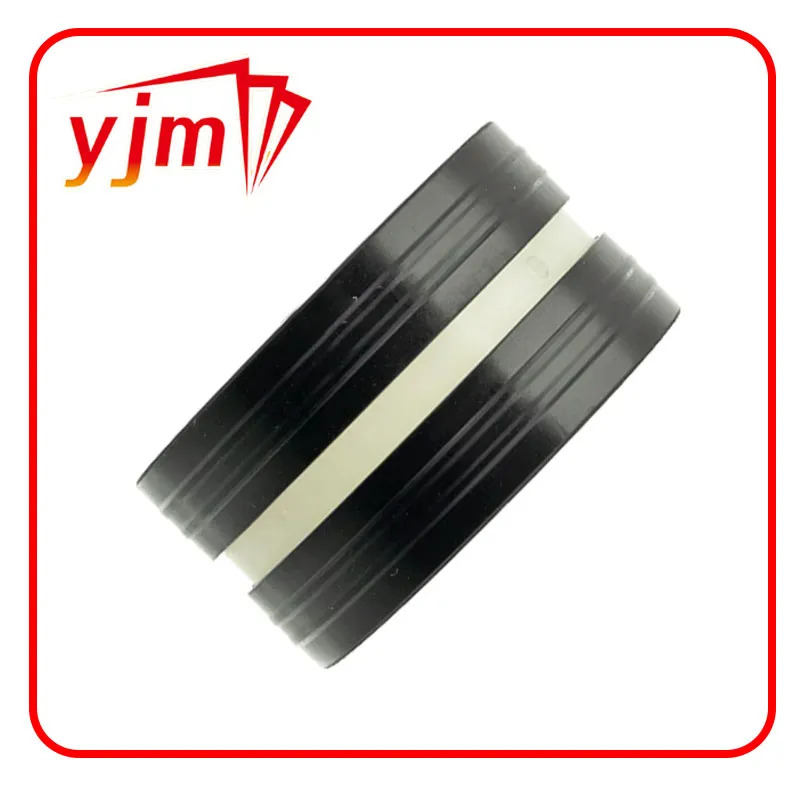

Synthetic elastomers, such as nitrile rubber (NBR) and fluorocarbon rubber (FKM), represent a significant leap forward in oil seal technology. Nitrile rubber is known for its excellent resistance to petroleum-based oils and fuels, making it ideal for sealing applications where exposure to these substances is common. Its ability to maintain flexibility and resilience in varying temperatures ensures that it performs reliably under a wide range of conditions.

Fluorocarbon rubber, on the other hand, offers superior resistance to high temperatures, chemicals, and extreme environmental conditions. This makes it suitable for high-performance vehicles and heavy-duty applications where traditional rubber compounds may fail. These synthetic elastomers not only extend the lifespan of the seals but also reduce the frequency of replacements and maintenance.

Composite Materials: Strength and Versatility About Front Drive Shaft Oil Seals

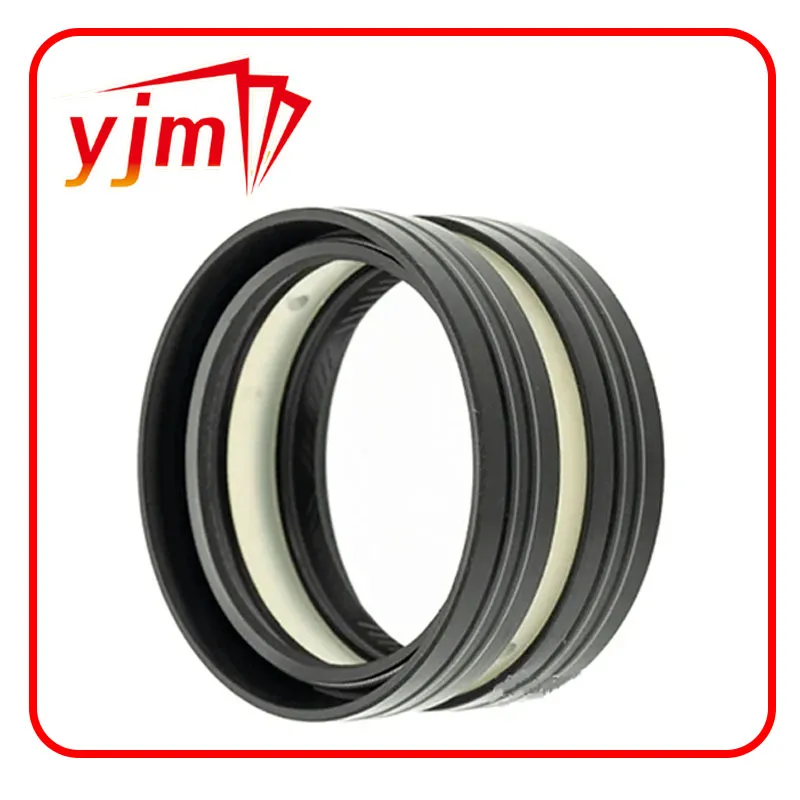

The incorporation of composite materials into front drive shaft oil seals has opened up new possibilities for enhancing performance. Composites, which combine materials like rubber with fabric or metal reinforcements, offer improved strength and durability. For example, seals made with fabric-reinforced composites can better withstand high pressures and dynamic loads, reducing the risk of deformation and failure.

Metallic composites, which integrate metals like steel with rubber compounds, provide additional resistance to wear and deformation. These materials are particularly useful in high-stress environments, such as off-road or racing conditions, where the drive shaft components are subjected to intense forces.

Temperature and Chemical Resistance About Front Drive Shaft Oil Seals

One of the primary challenges for front drive shaft oil seals is their exposure to extreme temperatures and harsh chemicals. Traditional materials often struggle to maintain their integrity under these conditions, leading to premature seal failure. Innovations in material science have addressed these issues by developing seals that offer enhanced resistance to heat, cold, and chemical exposure.

High-temperature seals made from advanced fluorocarbon rubbers or silicone elastomers can operate effectively in environments exceeding 200°C (392°F) without losing their sealing properties. These materials are also resistant to oxidation and chemical degradation, ensuring that the seals remain functional and reliable over time.

Conversely, seals designed for extremely low temperatures are made from elastomers that retain their flexibility and resilience even in sub-zero conditions. These innovations ensure that the seals can handle the full spectrum of temperature variations encountered in modern vehicles.

The Impact on Vehicle Performance and Maintenance About Front Drive Shaft Oil Seals

The adoption of advanced materials in front drive shaft oil seals has a significant impact on vehicle performance and maintenance. Enhanced durability and resistance to extreme conditions mean that these seals can perform effectively for longer periods, reducing the need for frequent replacements and repairs. This not only leads to cost savings but also contributes to improved vehicle reliability and safety.

Furthermore, better sealing performance translates to more efficient drivetrain operation. By preventing lubricant leaks and blocking contaminants, these advanced seals help maintain optimal lubrication, reduce friction, and prevent premature wear of the drive shaft components. This results in smoother operation, better fuel efficiency, and a more enjoyable driving experience.

Future Trends in Sealing Materials About Front Drive Shaft Oil Seals

Looking ahead, the trend towards even more advanced sealing materials is expected to continue. Research and development in material science are likely to bring about innovations such as self-healing materials, which can repair minor damages automatically, and smart seals equipped with sensors to monitor their condition in real time. These advancements will further enhance the performance and reliability of front drive shaft oil seals, aligning with the ongoing push towards more efficient and durable automotive components.

JULU YJM HWMF SEAL-Your Reliable Rubber Seals Manufacturer

Rubber seals play a vital role in industrial fields. Only by purchasing from trustworthy manufacturers can the quality and precision be guaranteed. JULU YJM HWMF SEAL CO., LTD is a leading manufacturer of rubber seals in China, With many years of industry experience and excellent reputation, is able to be come your reliable supplier. Contact us now to get more information.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories