Similar Oil Seal Specifications for Enhanced Performance and Durability

Understanding the 35% 2052 7 Oil Seal A Comprehensive Guide

When it comes to mechanical systems and machinery, maintaining optimal performance is crucial. One critical component that often gets overlooked is the oil seal. The 35% 2052 7 oil seal is a specific type of oil seal that plays an essential role in preventing oil leaks and ensuring the smooth operation of various machines. In this article, we will delve into what makes this oil seal significant, its applications, and the factors to consider when selecting the right one for your needs.

What is an Oil Seal?

An oil seal, also known as a shaft seal or radial seal, is designed to retain lubricating oil within the machinery while keeping contaminants like dirt and water out. It consists of a metal casing with a rubber lip that creates a tight seal around the rotating shaft. This prevents the leakage of oil and helps maintain pressure within the machinery, which is vital for its functionality and longevity.

The Importance of the 35% 2052 7 Oil Seal

The designation 35% 2052 7 refers to specific dimensions and material specifications that make this oil seal suitable for particular applications. The numbers can indicate the outer diameter, inner diameter, and the thickness of the seal. For instance, the first number may refer to the diameter of the shaft that the seal is designed to fit, while the other two could specify the dimensions of the seal itself.

Why is this oil seal important? In mechanical applications, oil seals help prevent costly oil leaks, which can lead to insufficient lubrication and, consequently, increased wear and tear on components. A malfunctioning seal can result in maintenance challenges, higher operational costs, and even catastrophic equipment failure. Hence, using the right oil seal is necessary for optimal machinery performance.

Applications of the 35% 2052 7 Oil Seal

The 35% 2052 7 oil seal finds its applications in various industries, including automotive, aerospace, manufacturing, and heavy equipment. In automotive engines, for instance, these seals are used to ensure that engine oil stays contained within the system, preventing leaks that could lead to engine damage. Additionally, in hydraulic systems, oil seals help maintain pressure and efficiency, allowing for smooth operations.

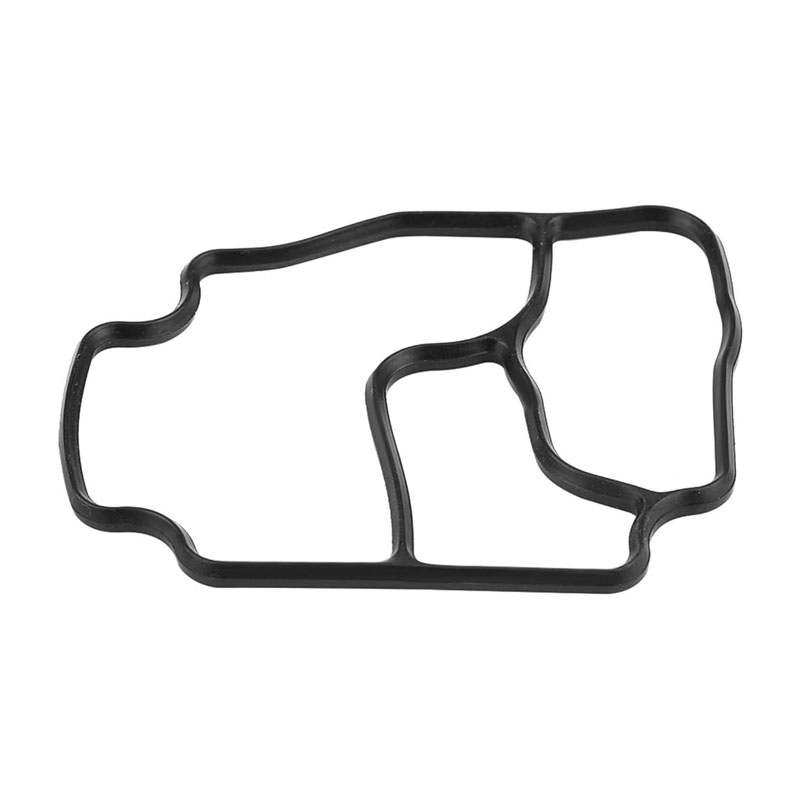

35 52 7 oil seal

Factors to Consider When Selecting an Oil Seal

When choosing an oil seal like the 35% 2052 7, several factors should be taken into account. These include

1. Material Composition Oil seals are made from different materials, such as rubber, silicone, and polyurethane. The choice of material affects the seal's durability, flexibility, and resistance to temperature and chemical exposure. Ensure that the material is compatible with the lubricants and conditions present in your application.

2. Dimensions Proper sizing is crucial for an effective seal. Incorrectly sized seals can lead to leaks and operational inefficiencies. Always verify the dimensions against the specifications of your machinery.

3. Operating Environment Consider the environment in which the oil seal will operate. Factors such as temperature extremes, exposure to aggressive chemicals, and the presence of dust or water can influence which type of seal is appropriate.

4. Brand and Quality Opt for reputable manufacturers that guarantee quality and performance. A well-made oil seal can significantly extend the life of your machinery.

Conclusion

In summary, the 35% 2052 7 oil seal is a vital component that ensures the longevity and efficiency of various mechanical systems. By understanding the importance of this oil seal and considering the factors mentioned when selecting one, you can enhance the performance and reliability of your machinery. Remember, investing in quality components like oil seals is not just a choice; it's a necessity for optimal operational efficiency.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories