O-Ring Maintenance for Oil Pumps to Ensure Efficient Performance and Longevity

Understanding Oil Pump O-Rings Importance, Functionality, and Maintenance

Oil pumps are crucial components in any internal combustion engine, responsible for circulating oil to lubricate moving parts and maintain optimal operating temperatures. Within this complex system, O-rings play a vital role, acting as seals that prevent oil leaks and ensure the efficient performance of the oil pump. This article delves into the significance of oil pump O-rings, their functionalities, and best practices for maintenance.

The Role of O-Rings in Oil Pumps

O-rings are circular gaskets usually made from rubber or other elastomeric materials. Their primary purpose in oil pumps is to form a tight seal between different components, such as the oil pump housing and the engine block. This sealing action is crucial in preventing oil from leaking out, which can lead to significant performance issues and potential engine damage due to inadequate lubrication.

In addition to preventing leaks, O-rings also serve as buffers that absorb vibrations and thermal expansions that occur during engine operation. This helps to preserve the integrity of the oil pump and other connected parts, ensuring longevity and consistent performance.

Types of O-Rings Used in Oil Pumps

When selecting O-rings for oil pumps, it’s essential to consider the materials they are made from, as this can significantly impact their effectiveness. Common materials include

1. Nitrile Rubber (NBR) Known for its excellent oil resistance, NBR is a widely used material for O-rings within oil pumps. It can withstand various temperatures, making it suitable for most engine applications.

2. Fluorocarbon (Viton) This high-performance material offers superior temperature resistance and chemical stability, making it ideal for high-performance or heavy-duty applications. Viton O-rings are resistant to a wider range of oils and fluids compared to NBR.

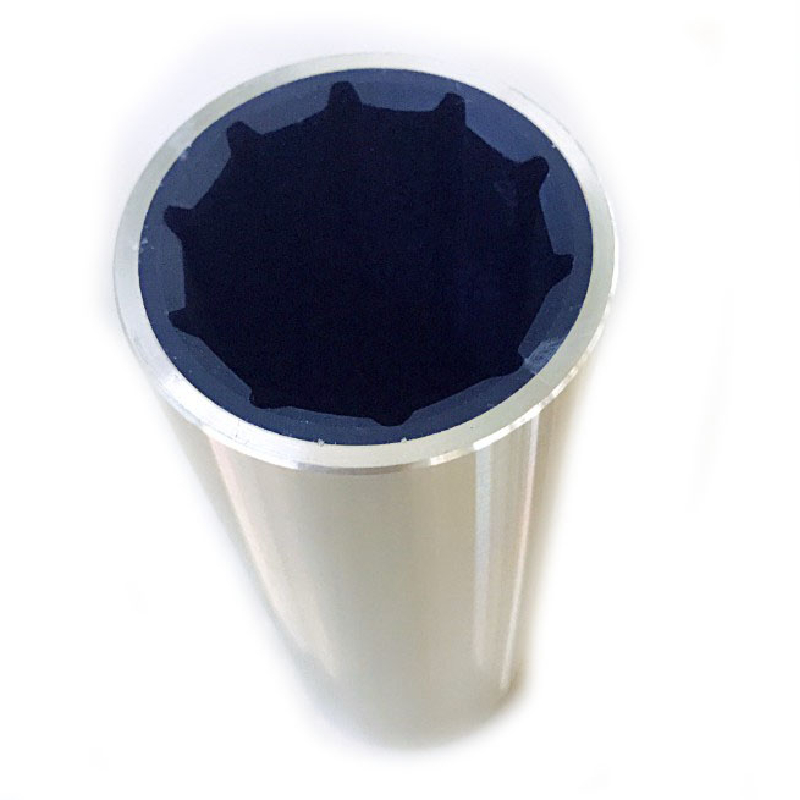

oil pump o ring

3. Silicone While less commonly used for oil applications due to its poorer oil resistance, silicone O-rings can still be found in oil pumps, especially in areas where temperatures are elevated and flexibility is required.

Importance of Regular Maintenance

To ensure the oil pump functions correctly, regular maintenance is essential. O-rings, like other engine components, can wear out over time due to exposure to heat, pressure, and various engine fluids. Signs of a failing O-ring include oil leaks, decreased oil pressure, and abnormal engine noise.

Preventative measures can be taken to prolong the lifespan of O-rings. These include

- Routine Inspections Regularly inspect the O-rings for signs of wear, cracking, or deformation. Early detection can prevent costly repairs and ensure reliable engine performance.

- Proper Installation During maintenance, it is crucial to install new O-rings correctly. Ensure that all surfaces are clean and free of debris before installation to prevent damage to the O-ring and ensure a proper seal.

- Use Quality Materials Always opt for high-quality O-rings that meet automotive standards. Using inferior products can lead to premature failure and increased maintenance costs.

Conclusion

Oil pump O-rings may seem like small components in the grand scheme of engine mechanics, but their role is indispensable. They provide essential sealing functions that prevent oil leaks and maintain lubrication throughout the engine. Understanding their significance and ensuring proper maintenance is key to prolonging the life of both the oil pump and the engine itself. Regular inspections, quality replacements, and correct installation practices will contribute to a well-functioning engine, enhancing performance and reliability in the long run.

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

Products categories