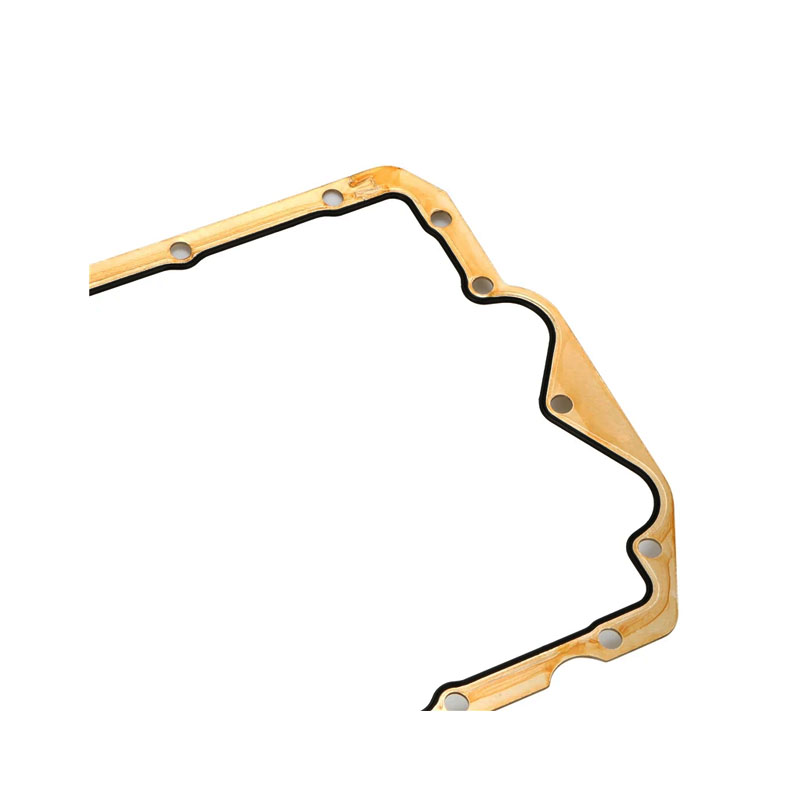

pan seal

The move towards more sustainable practices in industrial environments further highlights the importance of reliable seals like the 16x26x6. As industries strive to reduce waste and increase efficiency, the role of a dependable seal becomes ever more critical. Preventing leaks not only means fewer accidents and equipment failures but also aligns with global efforts to minimize environmental footprints. For industrial sourcing managers or equipment engineers looking to procure these seals, it is crucial to partner with reputable suppliers who offer certified and thoroughly tested products. Authenticity and compliance with industry standards cannot be compromised as they assure that seals can handle specified loads and temperatures consistently. Engaging with suppliers who provide technical support and comprehensive documentation ensures that every seal not only meets the infrastructure requirements but also contributes to the larger goal of operational excellence. Trust in the seal 16x26x6 comes from its time-tested performance and the continuous innovations that manufacturers incorporate to meet evolving demands. Through rigorous testing and ongoing advancements in material science, these seals continually adapt, offering improved resistance to wear and enhanced lifespan, fulfilling their role with increasing efficiency. Ultimately, the seal 16x26x6 is more than a simple component; it is a testament to the innovation and meticulous craftsmanship required in modern industrial processes. The confluence of experience and technical prowess in the creation and application of this seal underscores its fundamental place in ensuring machinery operates smoothly and safely, a small yet extraordinary part of our engineered world.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories