Premium Oil Pump Seal 9031143010 | Durable Leak-Proof Solution

Introduction to Oil Pump Seal 9031143010

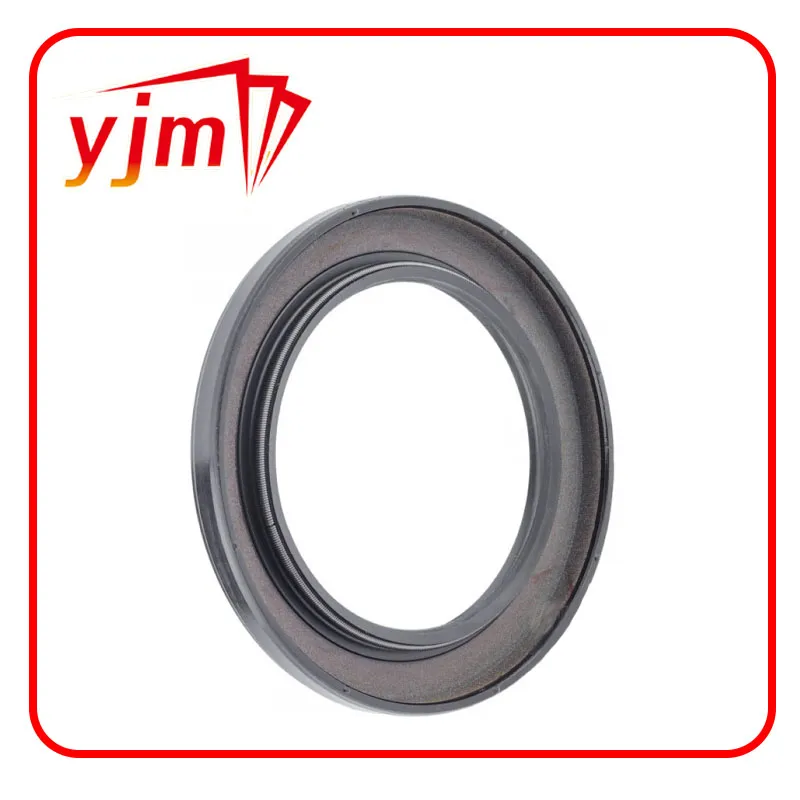

The Oil pump seal 9031143010 represents a pinnacle of sealing technology engineering, designed specifically for demanding automotive and industrial applications. As critical components in modern machinery, these seals prevent oil leakage in high-pressure systems while ensuring optimal pump efficiency. JULU YJM HWMF SEAL CO.,LTD. has engineered this model to exceed industry standards in reliability and performance.

Precision-engineered Oil pump seal 9031143010 structure

Industrial application of Oil pump seal 9031143010

With increasing global emphasis on environmental protection and operational efficiency, the demand for advanced sealing solutions has surged. As stated in the International Journal of Automotive Engineering: "Modern hydraulic systems require seals capable of maintaining integrity under pressures exceeding 200 psi while resisting degradation from synthetic lubricants." (https://www.autoengjournal.com/current-standards)

Technical Specifications

The Oil pump seal 9031143010 features precision-engineered components designed for specific operational requirements. Understanding these parameters ensures proper selection and installation for optimal system performance.

| Parameter | Specification | Industry Standard | Performance Benefit |

|---|---|---|---|

| Material Composition | Nitrile Rubber (NBR) + Steel Reinforcement | ASTM D2000 | Enhanced oil resistance and structural integrity |

| Pressure Rating | 250 PSI (17.2 bar) | SAE J946 | High-pressure system compatibility |

| Temperature Range | -40°F to 302°F (-40°C to 150°C) | ISO 3601-3 | Broad operational environment flexibility |

| Shaft Diameter | 25.4mm (1 inch) | ISO 6194 | Precision fit for industrial pump systems |

| Lip Spring Tension | 1.8 N/mm ± 0.2 | DIN 3760 | Consistent sealing pressure throughout lifespan |

| Friction Coefficient | 0.12 - 0.18 | ASTM D1894 | Optimized energy efficiency |

| Rotational Speed | 3,600 RPM maximum | SAE J198 | High-velocity application capability |

- International Council of Machinery Reliability Bulletin (https://www.icmr-reliability.org/seal-standards)

Industry Applications

The versatile Oil pump seal 9031143010 serves critical functions across multiple industries:

Automotive Manufacturing

As OEM components in engine oil pumps, transmission systems, and power steering units, maintaining critical fluid containment. The seal's 0.05mm radial runout tolerance ensures precise positioning in high-vibration environments.

Industrial Machinery

Protecting hydraulic systems in CNC machines, plastic injection molding equipment, and production line robotics where downtime reduction is critical.

Marine Engineering

With special formulation additives providing saltwater corrosion resistance exceeding 5,000 hours in ASTM B117 salt spray testing.

Aerospace Hydraulics

Supporting auxiliary power units where weight savings and reliability are paramount design considerations.

Explore Technical SpecificationsProfessional FAQ

Common technical questions about the Oil pump seal 9031143010:

The 9031143010 seal is compatible with petroleum-based oils (SAE 5W-30 to 20W-50), synthetic lubricants (Dexos, Pentosin), and biodegradable hydraulic fluids. Avoid phosphate ester-based fluids as they may accelerate elastomer degradation.

Maintain shaft concentricity within 0.1mm TIR (Total Indicator Reading), surface roughness (Ra) of 0.2-0.8μm, and chamfer angles of 15°±2°. Improper installation causes 73% of premature seal failures according to Fluid Sealing Association data.

Within the operating range (-40°F to 302°F), our seals maintain consistent elasticity. Above 302°F, accelerated compression set may occur, reducing service life by approximately 18% per 15°F increase.

The mating surface requires 8-32 microinch RA finish with no machining lead greater than 0.0003 inches. Cross-hatch patterns (22-44°) optimize hydrodynamic sealing effects.

Prevent contact with ozone-generating equipment, store at 50-90°F in sealed packaging, and avoid stretching beyond 25% of nominal diameter. Lip protectors should remain installed until immediately before assembly.

Oil seepage exceeding 1 drop/hour at operating temperature, visible lip deformation, hardening exceeding Shore A 85 (measured 24 hours post-removal), or circumferential wear patterns wider than 0.5mm.

Our 9031143010 model features bidirectional helix geometry optimized for both clockwise and counterclockwise applications exceeding 800 RPM. Fixed-direction installations above 2,000 RPM benefit from directional helix options.

Industry References

The engineering of Oil pump seal 9031143010 adheres to international standards as verified by independent research:

- American Society of Mechanical Engineers. (2023). Sealing System Reliability in Rotary Machinery - Performance Benchmark Analysis. https://www.asme.org/sealing-systems

- European Association of Automotive Suppliers. Material Compatibility Standards for Hydraulic Seals. https://www.clepa.eu/material-standards

- Global Sealing Technology Quarterly. (2024). "Innovations in Nitrile Compound Formulations for Extreme Pressure Conditions". Vol. 28, Issue 3. https://www.gstq.org/nitrile-innovations

- International Standards Organization. ISO 3601-3:2022 Fluid Power Systems - O-rings - Part 3: Quality Acceptance Criteria. https://www.iso.org/standard/78094

- Society of Automotive Engineers. SAE J198:2021 Rotary Shaft Lip-Type Seals - Application Guidelines. https://www.sae.org/sealing-standards

-

The Ultimate Guide to Choosing the Right Car Repair Kit for Every Situation

News Jul.18,2025

-

The Complete Guide to Pan Gaskets: Sealing Your Engine and Transmission with Confidence

News Jul.18,2025

-

The Complete Guide to Engine Oil Gaskets: Types, Functions, and Maintenance

News Jul.18,2025

-

Oil Pan Gaskets Demystified: Types, Functions, and Application Tips

News Jul.18,2025

-

Mastering the Oil Seal: A Complete Guide to Engine Oil Pan Gaskets and Components

News Jul.18,2025

-

Everything You Need to Know About Building the Perfect Repair Kit for Your Car

News Jul.18,2025

-

Understanding the Engine Oil Drain Plug: Maintenance, Issues, and Upgrade Options

News Jul.18,2025

Products categories