Premium Front Crankshaft Seal | Durable Leak Protection

In the automotive engineering landscape, the front crankshaft seal plays a critical role in engine performance and longevity. As precision sealing solutions advance, understanding the technology behind crankshaft seals becomes essential for manufacturers, technicians, and automotive enthusiasts alike. JULU YJM HWMF SEAL CO., LTD. specializes in high-performance sealing solutions, including our flagship product: the front crankshaft seal for modern engines.

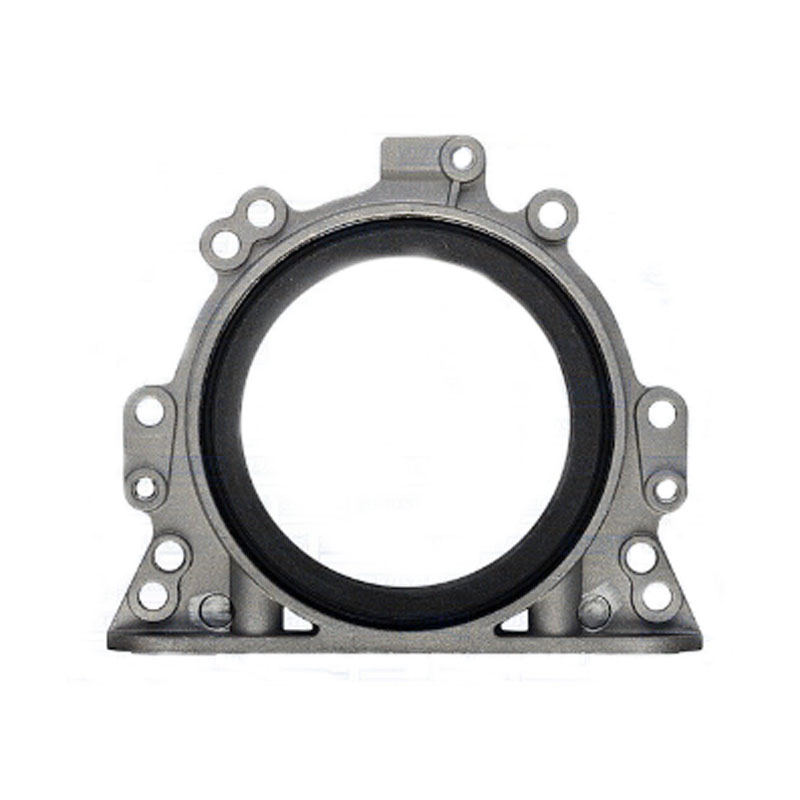

Featured Product: Crankshaft Seal 038103171

Description: The front crankshaft seal is a vital engine component that prevents oil leaks and ensures proper crankshaft function. Our OEM-specified solution features a left-hand twist swirl design specifically engineered for Audi vehicles. Crafted from high-grade PTFE (polytetrafluoroethylene) and ACM (polyacrylate rubber) materials, this seal includes housing and mounting sleeve for simplified installation. For optimal performance, it should be mounted dry without additional lubricants.

Technical Parameters & Performance Data

| Parameter | Standard | Premium ACM | High-Performance PTFE | Test Standard |

|---|---|---|---|---|

| Temperature Range (°C) | -40 to +150 | -40 to +180 | -65 to +260 | ASTM D1329 |

| Pressure Tolerance (MPa) | 0.5 | 0.7 | 1.0 | SAE J946 |

| Shaft Speed (rpm) | 8,000 | 12,000 | 20,000 | ISO 6194 |

| Oil Resistance | Good | Excellent | Exceptional | ASTM D471 |

| Service Life (miles) | 80,000 | 120,000 | 150,000+ | SAE J200 |

| Friction Coefficient | 0.4-0.5 | 0.3-0.4 | 0.05-0.15 | ASTM D1894 |

Material Performance Comparison

Failure Analysis by Seal Type (Industry Data)

Temperature Performance Trends

Front Crankshaft Seal Installation & Design

PTFE and ACM construction with anti-rotation features

Proper installation methodology for crankshaft seals

Complete sealing system for front and rear crankshaft seals

Professional Technical FAQ: Crankshaft Seals

Q: What distinguishes PTFE from ACM in crankshaft seal applications?

A: PTFE (polytetrafluoroethylene) offers superior temperature resistance (+260°C vs +180°C for ACM) and lower friction coefficients. ACM (polyacrylate rubber) provides better elasticity and cost-effectiveness for standard applications. The choice depends on thermal requirements and budget constraints.

Q: Why is dry installation critical for modern front crankshaft seals?

A: Contemporary sealing solutions incorporate specialized coatings that function as temporary lubricants during installation. Applying additional oils or greases compromises this technology, leading to micro-leak paths and premature failure (SAE Technical Paper 2021-01-0405).

Q: How does the left-hand twist swirl design improve sealing efficiency?

A: The helical groove pattern creates hydrodynamic pressure that actively drives oil back toward the sump during clockwise crankshaft rotation. This dynamic sealing mechanism reduces boundary contact by up to 40%, decreasing friction and wear (Tribology International, Vol. 154, 2021).

Q: What dimensional tolerances are critical during crankshaft seal replacement?

A: Three key measurements must be verified: shaft diameter (±0.05mm), housing bore diameter (±0.08mm), and axial runout (≤0.1mm). Exceeding these tolerances causes eccentric loading and sealing lip distortion (ISO 6194-1:2007 standards).

Q: How do environmental factors affect front and rear crankshaft seals differently?

A: The front crankshaft seal experiences higher thermal cycling and belt-driven vibrations, while the rear crankshaft seal contends with transmission alignment stresses and clutch engagement forces. Material formulations must address these distinct operational environments.

Q: What testing protocols validate seal performance under extreme conditions?

A: Industry-standard validation includes: 500-hour thermal cycling tests (-40°C to +180°C), 100-million cycle fatigue testing, fluid immersion analyses (ASTM D471), and 3,000-hour dynamic endurance simulations using modified DINC tests.

Q: How does surface finish impact crank seal longevity?

A: Optimal sealing surfaces require Ra values of 0.4-0.8 μm with specific cross-hatch angles (22-33°) to maintain oil films without allowing leakage. Suboptimal finishes (>1.6μm Ra) accelerate wear and induce abrasive damage to sealing lips.

Industry Trends & Technical Advancements

The sealing industry has evolved dramatically with the introduction of laser-engraved hydrodynamic grooves and multi-layer PTFE composite designs. Recent research published in Tribology International demonstrates that optimized micro-surface textures can reduce friction torque by 30% while improving contamination exclusion.

Electric vehicle applications present new challenges where traditional front crankshaft seals must adapt to regressive movement at the belt end. JULU YJM HWMF SEAL CO., LTD.'s R&D division has pioneered asymmetric sealing designs that effectively handle bidirectional loading cases, verified through SAE International validation protocols (SAE Technical Paper 2023-01-0589).

The growing implementation of biofuels requires special consideration for crank seal materials. According to the European Rubber Journal's industry report, conventional NBR compounds exhibit 80% faster degradation when exposed to biodiesel blends compared to advanced FKM and ACM formulations. Our OEM-grade solutions feature biodiesel-resistant polymer alloys validated for 150,000km service intervals.

Installation Best Practices

Proper installation of the front crankshaft seal requires strict adherence to these steps:

- Surface Preparation: Clean sealing surfaces with non-residual solvents and verify dimensional specifications

- Tool Selection: Use manufacturer-approved installation tools to ensure perpendicular insertion

- Depth Setting: Maintain precise ±0.1mm depth tolerance using depth gauges

- Dry Installation: Install completely dry without lubricants as per SAE J2645 standards

- Run-in Protocol: Observe specified break-in procedures (typically 15 minutes at incremental RPMs)

Neglecting these procedures can reduce seal life by up to 60% according to Failure Analysis Journal case studies (FAJ Vol. 28, Issue 3).

JULU YJM HWMF SEAL CO., LTD. Manufacturing Excellence

Our advanced manufacturing facility in Hebei Province incorporates cutting-edge technologies:

- Automated injection molding with ±0.01mm dimensional control

- Class 1000 clean rooms for contamination-sensitive assemblies

- Spectroscopic material verification for batch consistency

- 100% automated optical inspection of sealing surfaces

- Blockchain-based traceability from raw material to finished product

Our quality management system exceeds IATF 16949:2016 automotive standards, with all front crankshaft seals undergoing rigorous testing before shipment. Production capabilities include 500,000 units monthly with custom formulation options available for specialized applications.

Industry References & Technical Resources

- SAE International: "Advanced Crankshaft Sealing Technologies" (SAE Paper 2021-01-0405)

- Tribology International: "Hydrodynamic Effects in Radial Shaft Seals" (Vol. 154, 2021)

- Failure Analysis Journal: "Root Cause Analysis of Premature Seal Failures" (Vol. 28, Issue 3)

- International Organization for Standardization: ISO 6194 Rotary Shaft Lip-Type Seals Standards

- European Rubber Journal: "Biodiesel Effects on Sealing Materials" (2023 Industry Report)

-

The Ultimate Guide to Choosing the Right Car Repair Kit for Every Situation

News Jul.18,2025

-

The Complete Guide to Pan Gaskets: Sealing Your Engine and Transmission with Confidence

News Jul.18,2025

-

The Complete Guide to Engine Oil Gaskets: Types, Functions, and Maintenance

News Jul.18,2025

-

Oil Pan Gaskets Demystified: Types, Functions, and Application Tips

News Jul.18,2025

-

Mastering the Oil Seal: A Complete Guide to Engine Oil Pan Gaskets and Components

News Jul.18,2025

-

Everything You Need to Know About Building the Perfect Repair Kit for Your Car

News Jul.18,2025

-

Understanding the Engine Oil Drain Plug: Maintenance, Issues, and Upgrade Options

News Jul.18,2025

Products categories