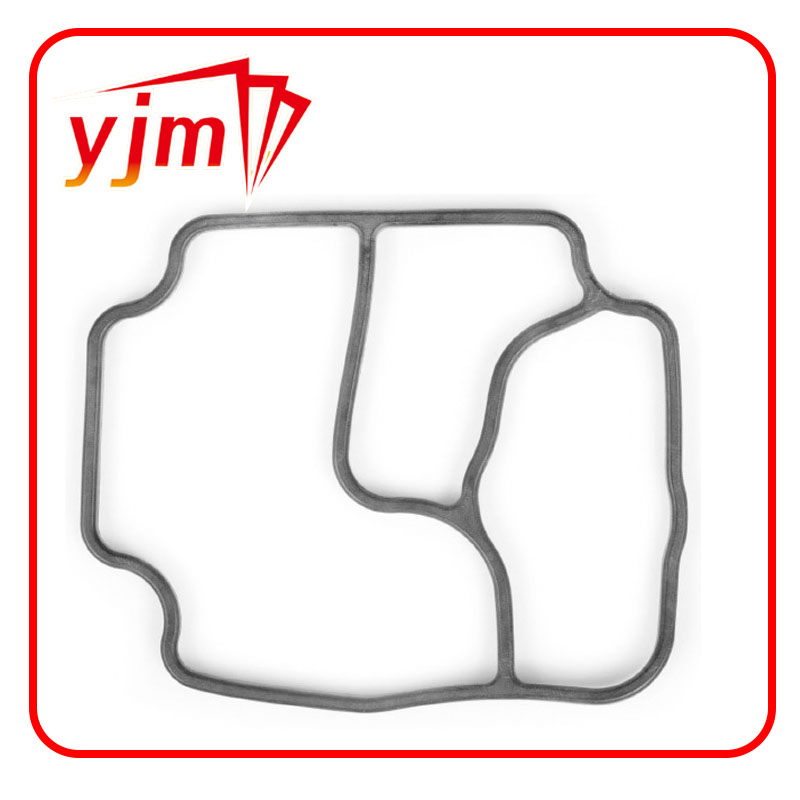

o ring x ring

Professional engineers and mechanics often find themselves opting for X-rings in higher-stress scenarios. This preference often boils down to the added durability and precision X-rings contribute. Experience reveals that the initial extra cost of X-rings can lead to considerable savings in maintenance and replacement costs in the long run. This is particularly true in industries such as aviation and high-performance automotive sectors where the integrity of seals cannot be compromised. As for trustworthiness, reputation is built on success and reliability. X-rings, in particular, have a track record for exceeding expectations in high-demand scenarios, effectively enhancing their adoption in professional settings. However, for manufacturers and novices alike, understanding material compatibility remains crucial. Both O-rings and X-rings are manufactured from a variety of materials such as silicone, nitrile, and fluorocarbon, each offering specific advantages tailored to the needs of the application, be it resistance to high temperatures, chemical exposure, or weather conditions. In conclusion, while both O-rings and X-rings are integral to the sealing process in mechanical applications, choosing the right one depends on the specific demands of the application. For general purposes, O-rings stand as a time-tested option, heavily favored for their simplicity and reliability. For conditions involving intense friction or dynamic movement, opting for X-rings could be the differential advantage one seeks. Mastery in application and understanding of these components embodies a blend of experience, expertise, authority, and trust, establishing an optimized framework within which industries can operate smoothly and efficiently.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories