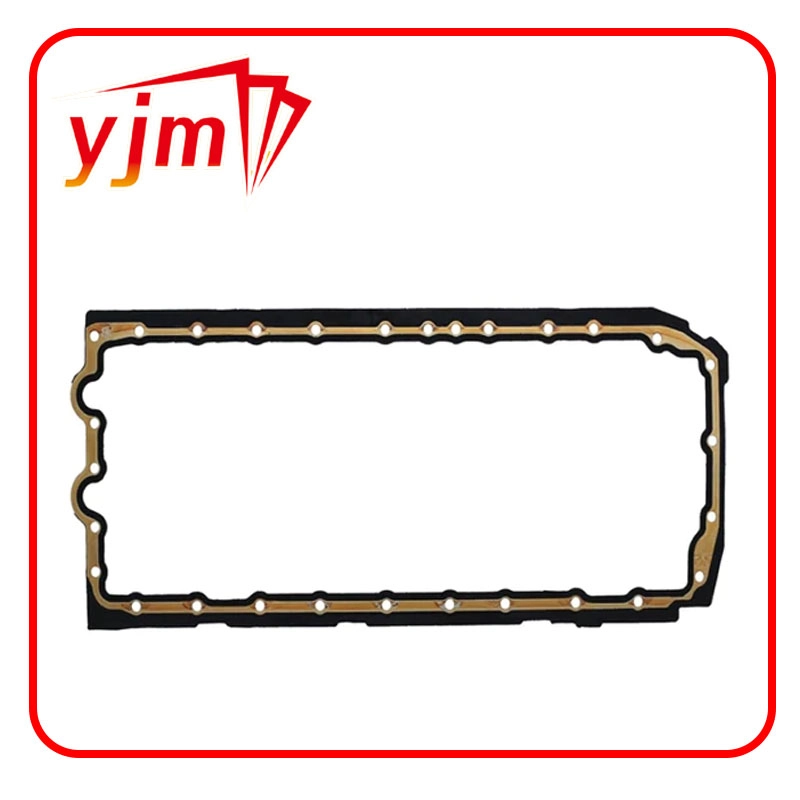

flat ring seal

Authoritativeness in the field is further underscored by standardized testing and certifications that O-ring flange seals must pass. These include ISO 3601 for dimensional standards, ensuring uniformity and quality across products. Such certifications work as benchmarks of trust for global industries, affirming that these seals meet or exceed the expected performance metrics. Companies investing in high-quality seals signal their commitment to safety and operational excellence, thereby fostering confidence among clients and partners. Personal experiences from seasoned engineers reveal the nuance in the application of O-ring flange seals. Installation requires meticulous attention to detail, with factors such as surface finish, flange alignment, and adequate torque playing crucial roles in achieving a perfect seal. Mistakes in any of these areas can lead to failures, emphasizing the need for skilled professionals in both the installation and maintenance stages. In terms of trustworthiness, customer testimonials and case studies serve as valuable testimonials. Success stories from industries that employ O-ring flange seals speak volumes about their reliability. One such case involved a chemical processing plant that reported significant reductions in down-time and maintenance costs after upgrading to high-grade O-ring flange seals. These real-world successes illustrate not only the seals' durability but also their cost-effectiveness over time. In conclusion, O-ring flange seals are quintessential in maintaining the integrity and efficiency of industrial operations. Their design and material choices demand a precise understanding of the application's environmental requirements, while their proven track record in various industries vouches for their reliability. Leveraging these insights, businesses can make informed decisions when selecting sealing solutions, ensuring safety and operational efficacy. This synthesis of expertise, authoritative standards, and real-world experiences makes O-ring flange seals an indispensable asset in any industrial toolkit.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories