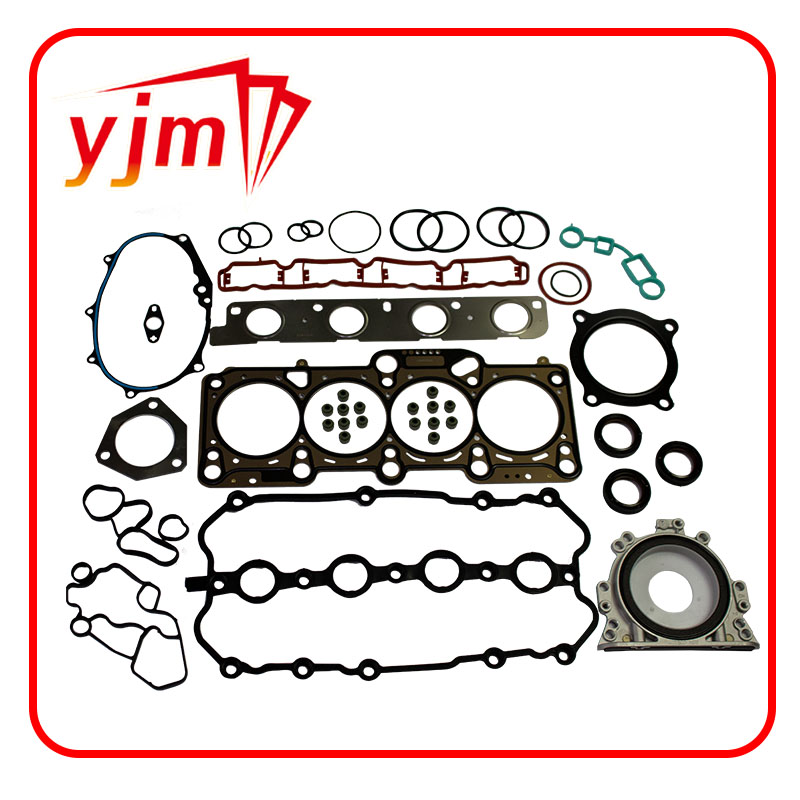

flat metal ring gasket

Supply Chain Dynamics The supply chain dynamics surrounding O-ring production and distribution also play an influential role in determining cost. Factors such as raw material availability, global manufacturing capacities, and logistical considerations can lead to fluctuations in pricing. For instance, geopolitical events that disrupt rubber production can lead to increased costs due to scarcity. Engaging with reputable suppliers who maintain robust inventory management systems and transparent supply chain practices can mitigate unexpected price hikes and ensure consistent quality and availability. Regulatory Compliance Industry regulations and compliance standards are pivotal in influencing O-ring costs, especially in sectors such as food and pharmaceuticals, where stringent sanitary requirements are enforced. Compliance with standards such as FDA, NSF, or ISO increases production costs due to the need for specialized materials and additional certification processes. While adhering to these regulations may increase cost, it ensures that the product performs safely and effectively within its intended application, protecting both the end-user and the manufacturer from potential liabilities. In conclusion, understanding the factors that determine O-ring costs is essential for businesses seeking to optimize their purchasing strategies. Material selection, manufacturing precision, dimensional specifications, supply chain dynamics, and regulatory compliance each offer unique challenges and opportunities. By leveraging industry expertise, businesses can assess these variables, ensuring they select the optimal O-ring solution that balances cost, performance, and reliability, ultimately enhancing the operational integrity of their systems. Leveraging the extensive expertise of manufacturers and suppliers, businesses can enhance their O-ring procurement strategy, ensuring seamless operations and lasting performance.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories