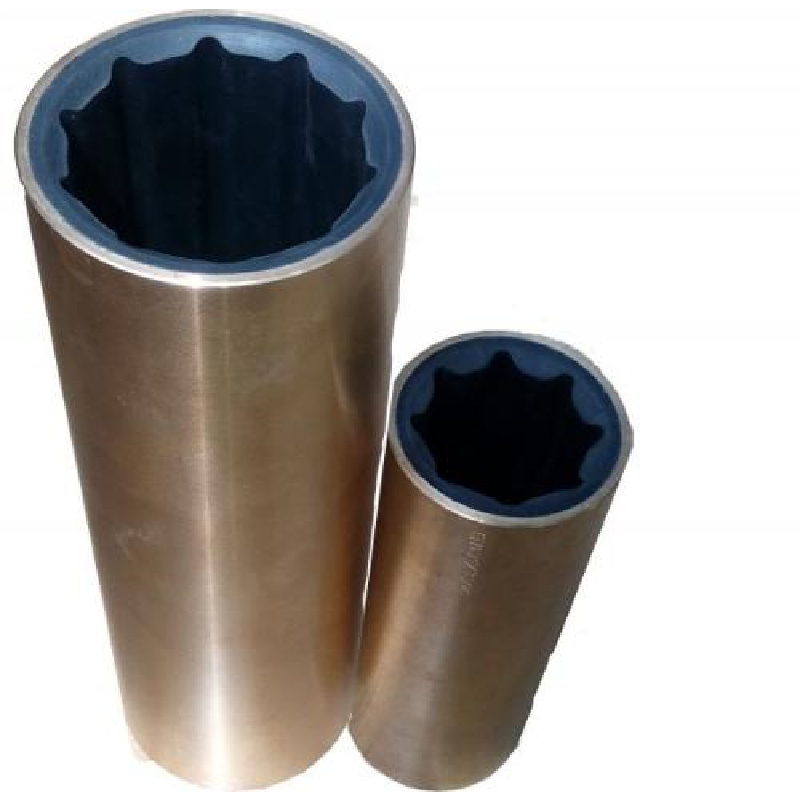

o ring copper

The Importance of O-Ring Seals in Copper Applications

O-rings are essential components in many industrial applications, serving as seals to prevent the leakage of fluids or gases. When made from materials such as rubber or thermoplastics, O-rings are commonly used in environments that can vary significantly in temperature and pressure. However, in certain applications—especially in industries utilizing copper components—metal O-rings, particularly copper O-rings, play a crucial role. This article explores the importance of O-ring seals in copper applications, their benefits, and considerations for their use.

Understanding O-Rings

An O-ring is a circular sealing device made from various materials and is traditionally used to create a barrier between two surfaces. Its design, which resembles a doughnut, allows it to seal spaces with varying diameters effectively. The mechanical attributes of the O-ring make it suitable for both static and dynamic sealing applications. When compressed between two surfaces, an O-ring deforms to fill the gaps, thus preventing the escape of fluids or gases.

Copper A Unique Element in Industries

Copper is a widely used metal known for its excellent conductivity and corrosion resistance. It is commonly found in plumbing, electrical components, HVAC systems, and more. The advantages of copper, however, come with specific requirements for sealing technologies. The expansion and contraction of copper due to temperature fluctuations can pose significant challenges, which is where O-rings become vital.

Benefits of Copper O-Rings

1. Corrosion Resistance Copper O-rings offer significant corrosion resistance, especially when used in environments exposed to moisture or chemicals. Unlike traditional rubber O-rings, copper does not deteriorate as quickly in harsh conditions, making it an ideal choice for certain applications.

2. Thermal Conductivity As mentioned earlier, copper is known for its thermal conductivity. When O-rings are made of copper, they can effectively dissipate heat, which is essential in applications involving high temperatures or where heat dissipation is critical.

3. Durability Copper O-rings are more durable than their rubber counterparts. They can withstand higher pressures and temperatures without losing their sealing integrity. This durability leads to reduced maintenance costs and longer operating life for machinery.

o ring copper

4. Reusability Many applications require seals that can be reused without losing their effectiveness. Copper O-rings can often be removed and reinstalled, making them a cost-effective choice for many industrial applications.

5. Compatibility with Other Materials Copper O-rings can be easily integrated with other metal components without the risk of reaction or degradation. This compatibility expands their usability in various mechanical assemblies.

Considerations for Use

While copper O-rings provide numerous benefits, there are several considerations to keep in mind

- Cost Copper O-rings can be more expensive than rubber alternatives. This initial investment may be offset by their longevity and reduced downtime.

- Installation The installation of copper O-rings requires careful handling to avoid scratching or damaging the surface. Proper techniques and tools must be used to ensure a reliable seal.

- Applications While copper O-rings excel in specific environments, they may not be suitable for all applications, particularly those that involve highly corrosive substances. It is essential to evaluate the compatibility of materials before use.

Conclusion

O-rings are a vital component in ensuring the efficiency and reliability of various industrial applications. When it comes to copper systems, utilizing copper O-rings presents numerous advantages, including superior durability, corrosion resistance, and the ability to withstand harsh operating conditions. While there are considerations regarding cost and installation, the long-term benefits far outweigh the challenges. As industries continue to innovate and push the boundaries of technology, the role of O-ring seals, especially copper O-rings, will become increasingly significant. Proper selection and application of these seals will undoubtedly contribute to the success and longevity of mechanical systems across numerous sectors.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories