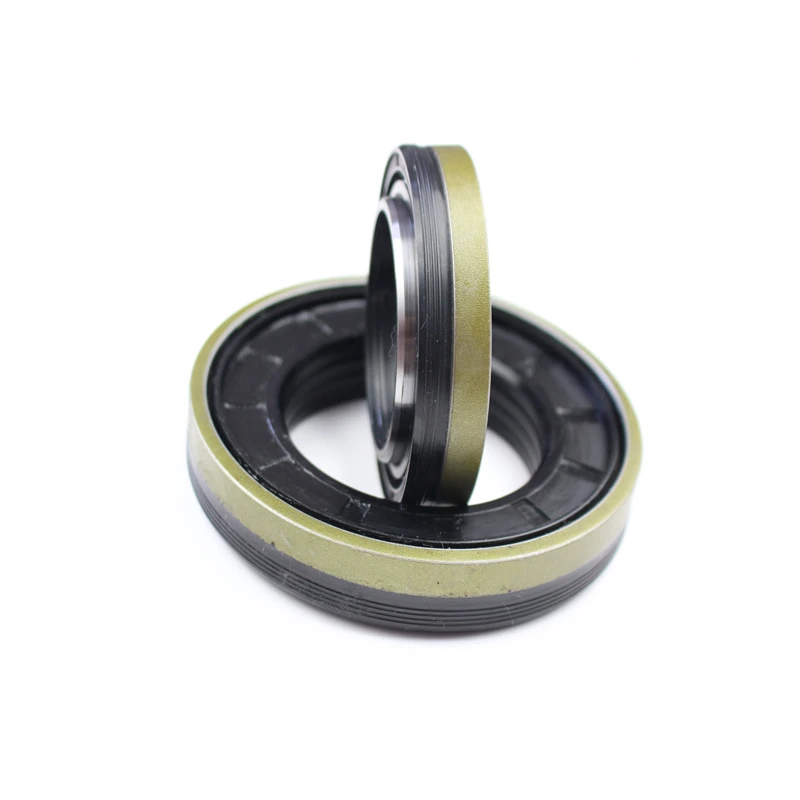

automotive oil seal

Operating speed can impact the performance of the oil seal as well. High-speed applications can generate heat, causing the sealing material to expand and potentially degrade. It is essential to select a seal capable of withstanding the operational speeds seen in your specific machinery to ensure long-term performance and safety. Installation of oil seals demands precision to avoid premature failure. Using the right tools, including an installation sleeve or bullet, prevents damage to the sealing lip during assembly. Furthermore, ensuring uniform seating of the seal in its housing guarantees consistent pressure around the shaft, reducing the likelihood of leaks. Regular maintenance checks should be conducted to identify signs of wear or potential failure early on. Symptoms such as lubricant leakage, unusual noises, or irregular equipment operation suggest it may be time for a replacement. Quick intervention can prevent further damage to machinery, saving time and cost in repairs. Selecting the right oil seal for your application requires a comprehensive understanding of the operating environment and technical specifications of your equipment. Consulting with a specialist can provide valuable insights and ensure optimal seal performance, preserving the integrity of your machinery and extending its lifespan. Ultimately, the oil seal plays an indispensable role in maintaining industrial productivity and machinery efficiency. By grasping its working principle and adhering to best practices in selection, installation, and maintenance, industries can optimize equipment functionality, ensuring reliability and safety across operations. Such informed practices reinforce trustworthiness and affirm expertise, keeping machinery running smoothly and effectively for years to come.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories