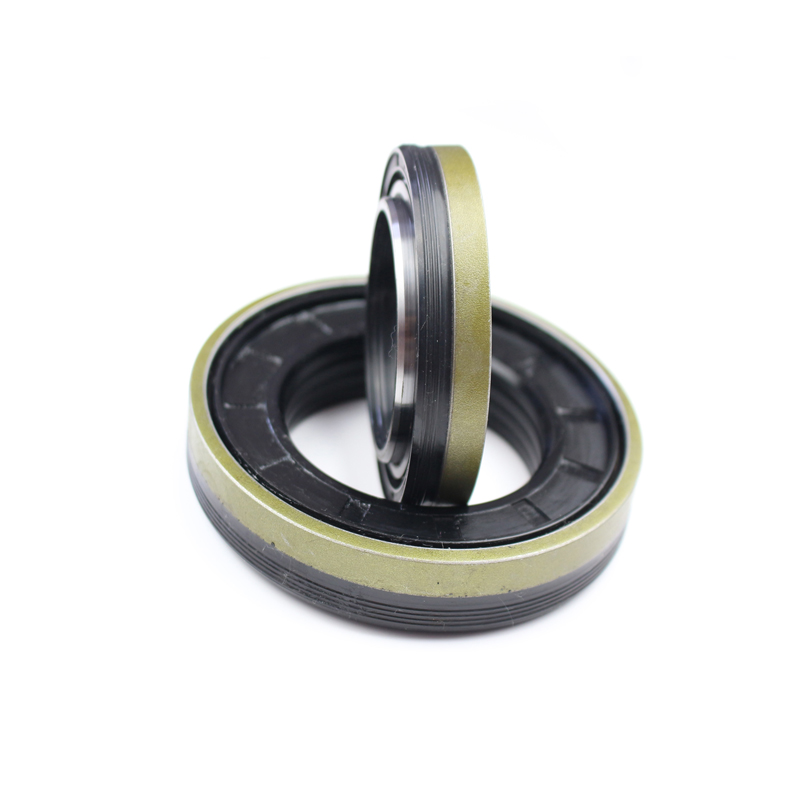

oil seal spring

Understanding the Importance of Oil Seal Springs

Oil seal springs, often referred to simply as seal springs, play a crucial role in various mechanical and automotive applications. These small yet significant components ensure the effective sealing of oil within different machinery, preventing leaks and contamination. Their design and functionality can greatly enhance the durability and performance of a vehicle or equipment. Let’s delve deeper into the importance, types, and applications of oil seal springs.

What are Oil Seal Springs?

Oil seal springs are typically composed of a metal coil that applies pressure on the lip of an oil seal. The oil seal itself is designed to prevent the leakage of lubricating oils and other fluids, thereby maintaining the desired levels of fluid within a system. The spring's primary function is to keep the sealing lip in contact with the rotating shaft or surface to create a reliable barrier against leakage.

The Functionality of Oil Seal Springs

The effectiveness of an oil seal largely depends on the pressure exerted by the spring. When the spring is compressed, it forces the lip of the seal against the shaft, which helps to accommodate any variances in alignment or wear that might occur during operation. This dynamic adjustment is vital in maintaining a secure seal, especially in high-speed or high-pressure applications.

Moreover, oil seal springs contribute to the overall longevity of the machinery. By preventing oil leaks, they not only protect the environment from contamination but also reduce the risk of damage to surrounding components due to lack of lubrication. In automotive engines, for instance, a good quality oil seal with an efficient spring system can prevent engine failure caused by oil starvation or overheating.

Types of Oil Seal Springs

Oil seal springs come in various designs, tailored for different applications and requirements

. The primary types include1. Constant Force Springs These springs provide a uniform pressure across the sealing lip throughout its operation, ensuring consistent performance. They are commonly used in applications where uniform sealing pressure is critical.

2. Bonnets or Caps These are typically used with rubber seals to provide additional strength and stability to the sealing system. The bonnet design helps in distributing the load evenly across the seal, improving its effectiveness.

oil seal spring

3. Metal Coil Springs These are traditional springs commonly used in oil seal applications. They are durable and able to withstand the rigors of various environments, making them ideal for automotive and industrial uses.

4. Spiral Springs Sometimes utilized in lighter duty applications, spiral springs offer flexibility and adaptability, which can be advantageous in specific sealing scenarios.

Applications of Oil Seal Springs

Oil seal springs are ubiquitous in various machinery and equipment, including

- Automotive Engines They are vital in engine components such as crankshaft seals and camshaft seals, preventing oil from leaking out and contaminants from entering.

- Pumps and Compressors In pumps, oil seal springs help maintain pressure and ensure that lubricants do not leak, which is crucial for operational efficiency.

- Industrial Machinery Many industrial machines utilize oil seals to prevent lubricant loss, contributing to the overall efficiency and longevity of the machinery.

- Hydraulic Systems Oil seal springs also play a critical role in hydraulic systems, where maintaining pressure and preventing fluid leakage is paramount.

Conclusion

In summary, oil seal springs may be small components, but their significance in industrial and automotive applications cannot be overstated. They provide essential support to oil seals, preventing leaks and ensuring the longevity of machinery. As technology advances, the design and materials used for oil seal springs continue to evolve, enhancing their effectiveness and durability. Properly functioning oil seal springs contribute not only to machinery efficiency but also to environmental protection by minimizing the risk of leaks and spills. Investing in high-quality oil seal springs can lead to significant long-term benefits for any mechanical system, emphasizing the importance of these often-overlooked components in machinery design.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories