oil seal maker

The Essential Role of Oil Seal Makers in Modern Industries

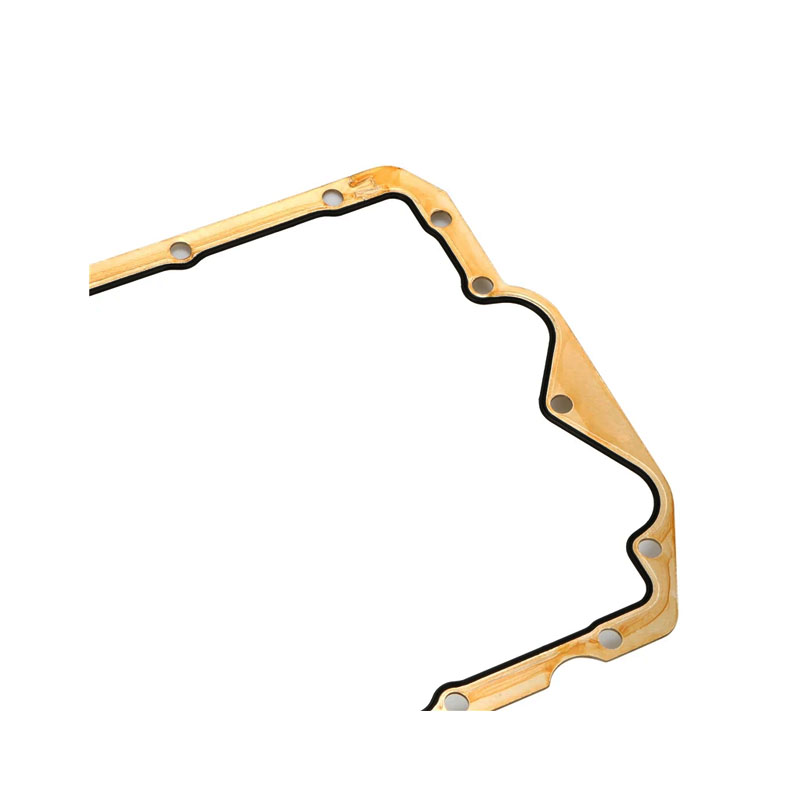

Oil seals, often overlooked in the broader landscape of manufacturing and engineering, play a crucial role in ensuring the efficiency and longevity of machinery. At the heart of this essential component's production are oil seal makers, who specialize in creating seals that are vital for preventing leaks and protecting equipment from contamination.

Oil seals are manufactured from a variety of materials, including rubber, metal, and plastic, tailored for specific applications and environmental conditions. These seals are designed to retain lubricant within machinery while keeping out dirt, dust, and other contaminants, thereby enhancing the performance of engines, pumps, and various mechanical systems. The effectiveness of an oil seal directly impacts the reliability and lifespan of the equipment, making the role of oil seal makers indispensable.

The process of designing and producing oil seals involves advanced engineering and precision manufacturing techniques. Oil seal makers leverage computer-aided design (CAD) software to create detailed models of seals that meet specific industry standards. These models undergo rigorous testing simulations to ensure they can withstand the extreme conditions of temperature, pressure, and chemical exposure they may encounter in the field.

oil seal maker

Quality control is paramount in the production of oil seals. Manufacturers implement strict testing protocols to evaluate the durability and performance of their products. This includes assessing the material's resistance to wear and tear, flexibility, and compression set, among other properties. Only those seals that pass these stringent tests are approved for distribution, ensuring that industries can rely on their efficacy.

In recent years, the demand for high-quality oil seals has surged, driven by the growth of automotive, aerospace, and industrial applications. As machinery becomes more advanced and precision-oriented, the need for effective sealing solutions increases. Oil seal makers are thus continually innovating, developing new materials and designs to meet the evolving needs of various sectors.

Sustainability is also becoming a key focus for oil seal makers. Many manufacturers are exploring eco-friendly materials and processes to reduce their environmental impact. By embracing sustainable practices, oil seal makers are not only contributing to the industry's innovation but also aligning with the global push for greener manufacturing.

In conclusion, the role of oil seal makers is critical in ensuring the reliability and efficiency of machinery across various industries. Their expertise in designing and manufacturing high-quality seals contributes significantly to the performance of equipment, ultimately driving productivity and innovation in the market. As industries continue to evolve, the importance of skilled oil seal makers will only grow, reinforcing their position as vital players in modern manufacturing.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories