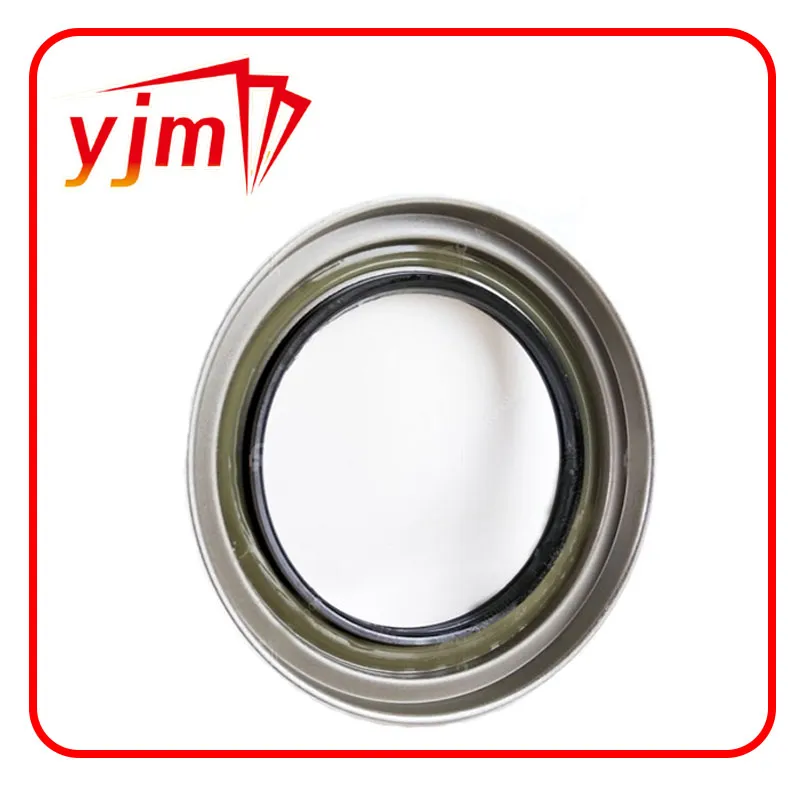

oil seal factory

In the realm of industrial machinery and automotive applications, oil seals play a pivotal role in ensuring efficiency and longevity. An oil seal factory that stands out in today's competitive market must be rooted in a commitment to innovation, quality, and customer satisfaction. As an SEO strategist deeply entrenched in the industry’s intricacies, I present insights into establishing such a factory, focusing on Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Experience serves as the cornerstone of an oil seal factory's reputation. It encompasses years of research, the mastery of manufacturing processes, and a profound understanding of varied sealing solutions. A successful factory doesn't just manufacture products; it evolves with technology. The utilization of state-of-the-art equipment such as CNC machinery and 3D modeling assures precision in design and production. Investing in experienced engineers who understand the nuances of different industrial applications—from heavy machinery to automotive engines—further solidifies a factory's standing in the industry.

Expertise is demonstrated through the factory's ability to produce a wide range of oil seals, tailored to meet diverse client needs. This includes rotary shaft seals, hydraulic seals, and more. Expertise goes beyond production; it encompasses advanced material science to select materials like Nitrile Rubber (NBR), Fluoroelastomers (FKM), and Silicone, known for their excellent resistance to temperature extremes and chemical exposure. The factory’s R&D team must continuously collaborate with material scientists and mechanical engineers to innovate and enhance product performance, maintaining the factory’s competitive edge.

Authoritativeness is derived from a factory's industry accolades and certifications. Compliance with international standards such as ISO 9001 for quality management systems ensures that the factory adheres to globally recognized benchmarks for product quality. Partnering with industry leaders and participating in global conferences also elevate a factory’s status. Sharing whitepapers, research findings, and real-world case studies on industry platforms establishes the factory as a thought leader, providing valuable insights into future trends in oil seal technologies.

Trustworthiness is achieved through consistent delivery on promises and a customer-centric approach. This involves meticulous quality control processes where each oil seal undergoes rigorous testing for durability, leak resistance, and performance. Offering warranties and flexible customer service options enhances reliability. Transparent communication is also crucial, from consultation and production updates to after-sales support. Establishing an omnichannel feedback system allows customers to share experiences and suggests improvements, building a community of satisfied clients who advocate for the brand.

In summary, an oil seal factory poised for success must integrate Experience, Expertise, Authoritativeness, and Trustworthiness into its operational ethos. It’s not just about manufacturing a product; it’s about crafting a legacy of excellence and innovation, aligning with industrial advancements, and fostering long-term relationships with clients across the globe. These pillars ensure the factory not only meets but exceeds the demanding expectations of today’s market, thereby securing a dominant position in the industry.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories