oil seal companies

Understanding Oil Seal Companies A Key Component in Engineering and Manufacturing

Oil seals, also known as grease seals, play a crucial role in the functioning and longevity of machinery across various industries. These components are designed to prevent the leakage of lubricants while keeping contaminants out, ensuring smooth operational efficiency. The demand for high-quality oil seals has led to the emergence of numerous specialized oil seal companies, each with its unique offerings and expertise.

The Importance of Oil Seals

Oil seals serve multiple vital functions in mechanical systems. They are primarily used to keep lubricants contained within moving parts, reducing friction and wear, which can lead to premature failure of machinery. Furthermore, they protect against dust, dirt, and moisture ingress, which can compromise the functionality of precision components. Without effective oil seals, industrial equipment, automotive systems, and household appliances would suffer from increased maintenance costs and shorter lifespans.

Market Overview

The oil seal market has witnessed significant growth in recent years, driven by advancements in automotive technology, the expansion of manufacturing industries, and the ever-increasing demand for efficient machinery. Major players in this sector have adapted to the evolving customer demands by developing seals that not only perform better but are also made from materials that can withstand harsh environmental conditions.

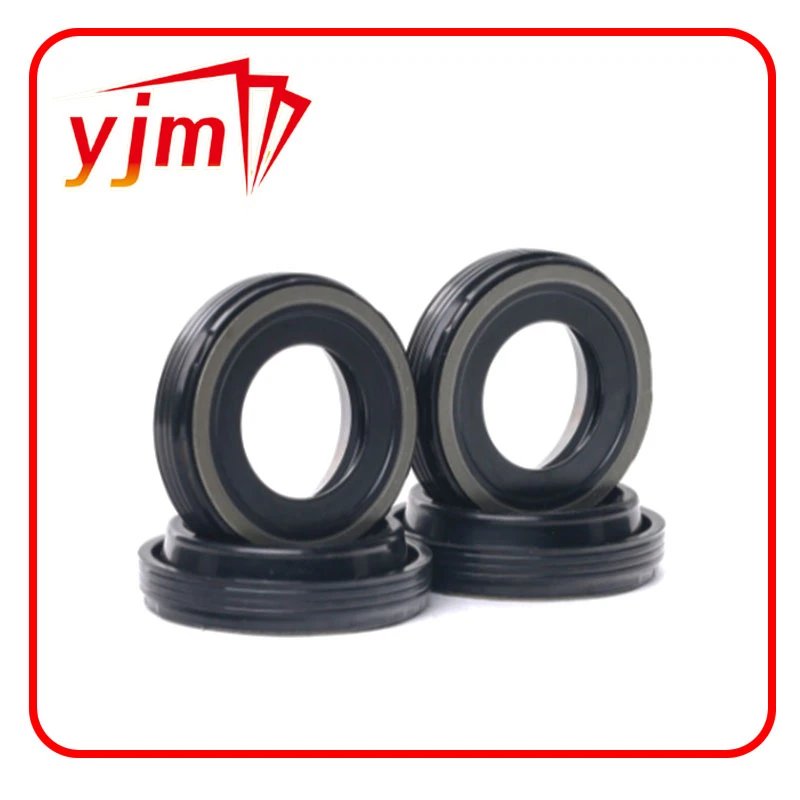

Oil seal companies typically offer a wide range of products, including radial shaft seals, rotary shaft seals, lip seals, and labyrinth seals. These seals come in various materials such as rubber, silicone, and thermoplastics, catering to specific applications and operational requirements. The choice of material is critical, as it impacts the seal's resistance to temperature, pressure, and chemical exposure.

Notable Companies in the Industry

There are several key players in the oil seal manufacturing sector known for their innovation, quality, and customer service. Companies such as SKF, National Oil Seals, and Parker Hannifin are recognized for their contribution to the development of advanced sealing solutions. These companies leverage extensive research and development to optimize the design and performance of their products.

oil seal companies

SKF, a Swedish multinational, has established itself as a leader in the bearing and seal industry. With a commitment to sustainability and innovation, SKF focuses on delivering reliable sealing solutions that enhance the efficiency and reliability of machinery. Their extensive product range includes oil seals designed for various industrial applications.

National Oil Seals, a division of National Rubber Corp, specializes in manufacturing oil seals for automotive and industrial applications. Their products are engineered to meet stringent quality standards, ensuring long-lasting performance. They also offer custom solutions tailored to specific customer needs, highlighting their flexibility and customer-centric approach.

Parker Hannifin, another prominent player, is renowned for its aerospace and industrial components, including oil seals. The company emphasizes a solutions-oriented approach, working closely with clients to develop sealing solutions that best meet their operational challenges.

Innovations and Trends

The oil seal industry is witnessing a shift towards enhanced performance through technological innovations. Manufacturers are increasingly utilizing advanced materials such as fluoropolymers and thermoplastic elastomers, which exhibit superior chemical and temperature resistance. Additionally, there is a growing trend towards the integration of smart technology within seals, enabling real-time monitoring of seal performance and potential failures.

Sustainability is also becoming a focal point, with many companies striving to produce more environmentally friendly seal options. This includes the use of recyclable materials and the development of seals that minimize environmental impact throughout their lifecycle.

Conclusion

Oil seal companies are integral to ensuring the efficient operation of machinery across a wide array of industries. As technology continues to advance, these companies are poised to innovate further, delivering high-performance sealing solutions tailored to modern engineering demands. With the ongoing emphasis on quality, sustainability, and innovation, the future of the oil seal market appears bright, promising continued growth and efficiency in mechanical applications. For businesses and consumers alike, understanding the role and value of oil seals is essential for maintaining the reliability and longevity of their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories