Exploring the Benefits and Applications of Flat Seal Rings in Various Industries

Understanding Flat Seal Rings Design, Materials, and Applications

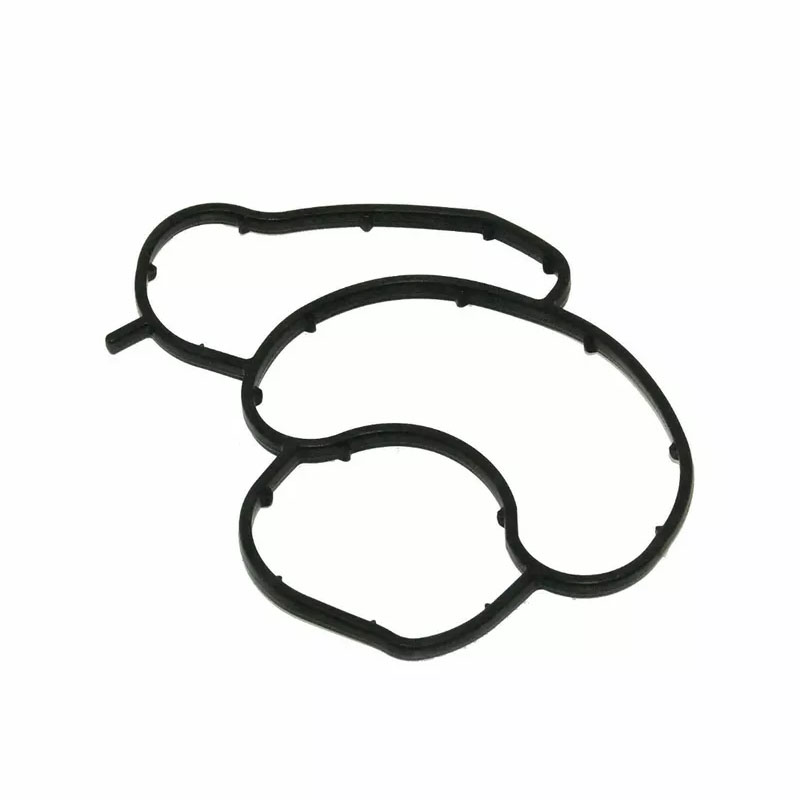

Flat seal rings, sometimes referred to as flat gaskets or flat sealing rings, are integral components used in various industrial applications to prevent leakage between mating surfaces. Their simple design and versatility make them one of the most common sealing solutions across different sectors, including automotive, aerospace, chemical processing, and more. In this article, we will explore the design, materials, and applications of flat seal rings, highlighting their importance in maintaining efficiency and safety in any given system.

Design Characteristics

Flat seal rings are typically designed as circular discs that fit snugly between two mating surfaces. Their primary purpose is to create a tight seal to prevent the escape of fluids or gases, which is critical in applications where pressure and temperature variations may be significant. The design considerations for flat seal rings include the thickness, outer diameter, inner diameter, and surface finish.

The thickness of a seal ring affects its compressibility and, consequently, its sealing capability. Thicker rings might provide a better seal but may require more force for installation, while thinner options are easier to install but might not withstand higher pressures. The choice of outer and inner diameters is determined by the specific application needs, ensuring compatibility with the dimensions of the mating surfaces.

Surface finish, on the other hand, plays a crucial role in the seal’s effectiveness. A smooth surface can promote better contact and a more effective seal, while a rougher finish may impede the seal’s ability to prevent leakage.

Materials Used

The materials used to manufacture flat seal rings are diverse, designed to suit different operational environments. Common materials include rubber, silicone, cork, metal, and composite materials.

1. Rubber Neoprene and EPDM (Ethylene Propylene Diene Monomer) are popular choices because they exhibit excellent resistance to water, ozone, and various chemicals. They are often used in plumbing and automotive applications.

2. Silicone Known for its high-temperature resistance and flexibility, silicone is often selected for applications where extreme temperatures are a factor, such as in the food and beverage industry.

3. Cork This natural material is often used in applications that require a compressible seal but can be susceptible to moisture and certain chemicals.

flat seal ring

4. Metal Flat seal rings made from materials such as stainless steel or aluminum offer high strength and durability, making them suitable for high-pressure applications.

5. Composite These materials can combine the benefits of two or more substances, providing enhanced performance characteristics. For example, a glass-reinforced composite may be used in applications requiring higher strength and low weight.

Applications

Flat seal rings have a wide array of applications across various industries

1. Automotive In vehicles, flat seal rings are used in engine assemblies, transmissions, and cooling systems to prevent leakage of oils and coolants, ensuring optimal performance and preventing damage from leaks.

2. Aerospace In the aerospace sector, seal rings are crucial in maintaining the integrity of fuel systems and hydraulic systems, where even the tiniest leak can lead to failures or dangerous situations.

3. Chemical Processing In chemical plants, flat seal rings are used to contain hazardous substances, preventing leaks that could cause safety incidents or environmental damage.

4. Food and Beverage The food industry relies on silicone and rubber flat seal rings to ensure sanitary conditions in processing equipment and packaging systems.

5. HVAC In heating, ventilation, and air conditioning (HVAC) systems, flat seal rings are used to prevent air leaks in duct connections and ensure energy efficiency.

Conclusion

In summary, flat seal rings are crucial components that provide effective sealing solutions across numerous industries. Their design and material choices play significant roles in their performance, durability, and suitability for specific applications. Understanding how these components work and where they are applied can help industries maintain efficiency, safety, and reliability while preventing costly leaks and failures. With continuous advancements in materials and manufacturing processes, the future of flat seal rings promises even greater performance and versatility in a wide range of applications.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories