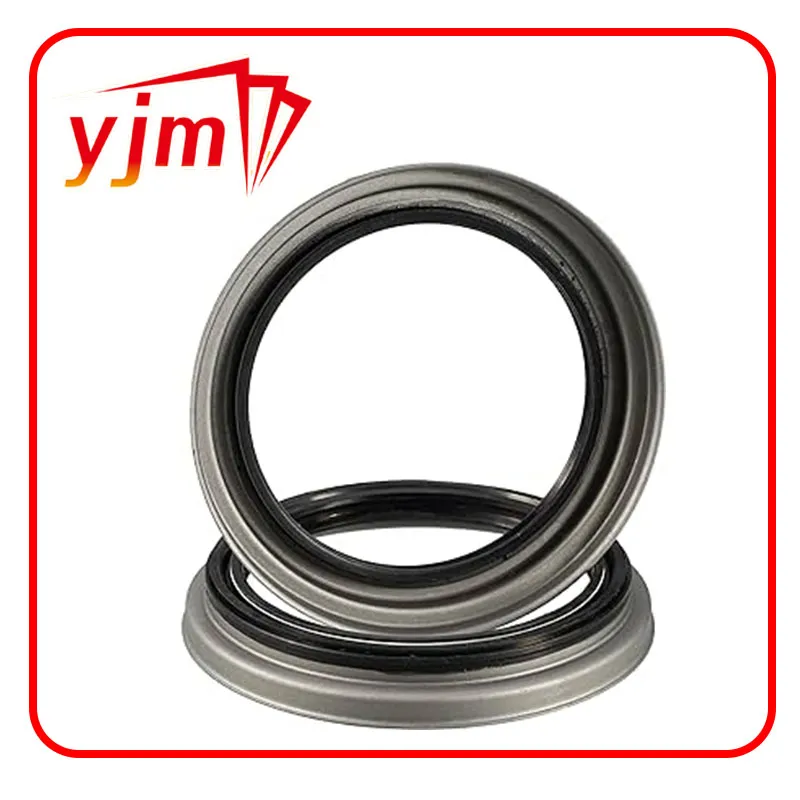

oil crush washer

Understanding Oil Crush Washers Essential Components for Mechanical Integrity

In the world of mechanical assemblies, ensuring the integrity of joints and connections is paramount for reliability and safety. Among various components that contribute to sealing and preventing leaks, oil crush washers have emerged as critical elements in automotive, aerospace, and industrial applications. This article aims to delve into the significance of oil crush washers, their function, types, and best practices for use.

What is an Oil Crush Washer?

An oil crush washer, often referred to as a crush washer, is a type of sealing washer designed to provide a leak-proof seal in a variety of applications where fluids like oil need to be contained. These washers are typically made from soft metallic materials such as aluminum or copper, and their structure is intended to deform or crush under pressure. This deformation creates a tight seal that prevents leaks from threaded joints, particularly in oil pans, fuel lines, and hydraulic systems.

How Do Oil Crush Washers Work?

The mechanism of an oil crush washer is relatively straightforward but highly effective. When a bolt or nut is tightened against the crush washer, the washer is compressed and flattened. This compression not only enhances the washer’s surface area contact with the mating surfaces of the assembly but also allows it to fill any microscopic irregularities in those surfaces. As a result, this significantly reduces the chances of fluid leakage.

Importantly, the effectiveness of the crush washer heavily relies on proper installation. If the washer is not compressed adequately, or if it is reused multiple times, it may fail to seal effectively, leading to leaks. Therefore, choosing the correct washer thickness, material, and ensuring it is new and free from defects is crucial.

Types of Oil Crush Washers

Oil crush washers come in various shapes and sizes to accommodate different applications. Here are a few common types

oil crush washer

2. Aluminum Washers Lighter than copper, aluminum washers are often used in low-pressure applications. Their softness allows for good sealing characteristics, making them suitable for use in oil drain plugs and similar fittings.

3. Fiber Washers While not metallic, fiber washers are also used in specific applications where non-metallic sealing is preferred. They can handle lower temperatures and pressures, making them suitable for certain fluids but not typically for oils.

4. Rubber Gasket Crush Washers These are often reinforced with a metal core and provide excellent sealing properties for various fluids. They can be an option in scenarios where flexibility and sealing are especially critical.

Best Practices for Using Oil Crush Washers

1. Always Replace It’s advisable to always use a new crush washer when reassembling components. Reusing old washers can compromise the seal and lead to leaks.

2. Avoid Over-Torquing While it may be tempting to tighten a bolt excessively to ensure a tight seal, over-torquing can actually damage the washer, leading to its failure. Refer to torque specifications provided by manufacturers to avoid this issue.

3. Choose the Right Size Always select the correct diameter and thickness for your application. A washer that is too small may not cover the entire surface area, while one that is too thick may not compress adequately.

4. Inspect Before Installation Always inspect new washers for defects, such as cracks or uneven surfaces, which could impact their sealing ability.

Conclusion

Oil crush washers play a critical role in maintaining the integrity of mechanical systems by preventing fluid leaks. Understanding their function, types, and best practices for use can significantly improve the reliability and safety of your applications. Whether you are involved in automotive repairs, industrial manufacturing, or any other field that requires secure mechanical connections, investing in the right oil crush washers can save time, money, and prevent potentially hazardous situations.

-

Understanding Cassette Seals: The Advanced Solution for Sealing Performance

News Jun.17,2025

-

The Vital Role of Front and Rear Crankshaft Seals in Engine Health

News Jun.17,2025

-

The Ultimate Guide to Heavy Duty Seals: Durability for Every Application

News Jun.17,2025

-

Mastering Engine Protection: Understanding the Role of the Crankshaft Oil Seal

News Jun.17,2025

-

Engine Leak Prevention: The Importance of the Crankshaft Front Oil Seal and Gasket Components

News Jun.17,2025

-

Choosing the Right Oil Seal: Comparing TTO Seals, CFW Oil Seal, Stefa Seals, and More

News Jun.17,2025

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

Products categories