Understanding the Importance of Oil Crush Washers in Mechanical Applications

The Essential Role of Oil Crush Washers in Automotive and Industrial Applications

In the realm of automotive and industrial applications, oil crush washers, also known as crush seals or crush washers, play a pivotal role in ensuring the integrity of fluid systems. These simple yet effective components are designed to create a reliable seal between two surfaces, typically where a bolt or fitting interfaces with a component like an engine block or oil pan. This article delves into the importance, function, and benefits of using oil crush washers in various applications.

Understanding Oil Crush Washers

Oil crush washers are typically made from materials such as copper, aluminum, or nylon. Their design enables them to deform under pressure, creating a tight seal that prevents fluid leakage. When a bolt is tightened, the washer compresses and fills any microscopic gaps between the surfaces it contacts, effectively blocking the escape of oil or other fluids. This property is particularly crucial in high-pressure environments, where even the smallest leak can lead to significant operational issues.

Importance in Automotive Applications

In automotive systems, oil crush washers are integral to the maintenance of engine components. For instance, when changing engine oil, a new crush washer is often recommended to be installed with the oil drain plug. This practice ensures that the plug seals effectively, preventing oil leaks that can severely damage an engine over time. Moreover, many vehicles utilize crush washers in their oil filter assemblies and transmission systems, where reliable sealing is essential for optimal performance and safety.

The use of oil crush washers extends beyond normal maintenance; they also play a critical role in preventing catastrophic failures. Oil leaks can lead to inadequate lubrication, resulting in increased friction and wear on engine components, overheating, and eventually engine failure. By ensuring a perfect seal, crush washers mitigate these risks, contributing to the longevity and reliability of automotive systems.

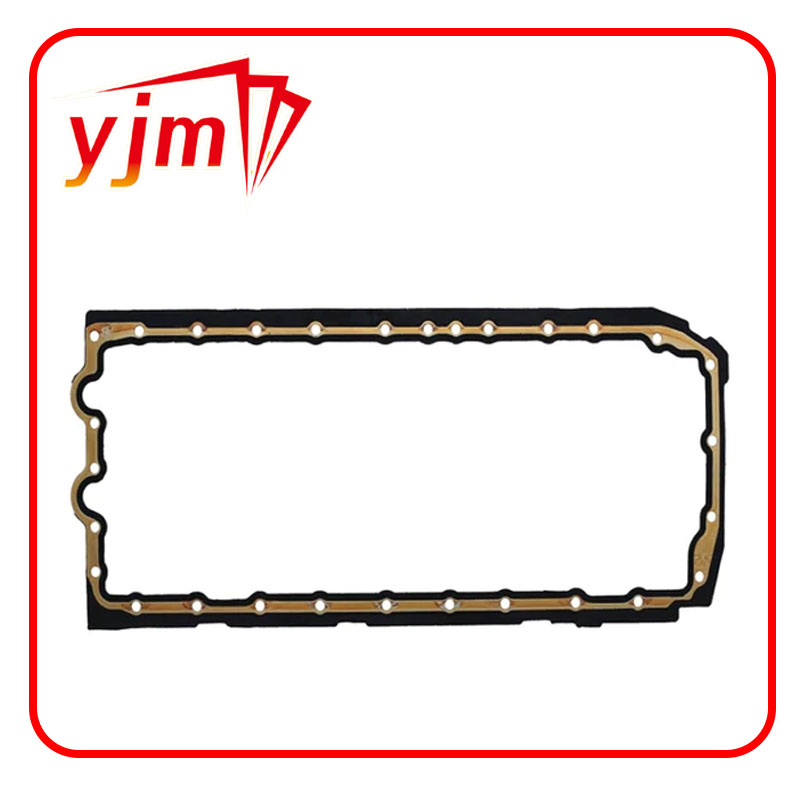

oil crush washer

Applications in Industrial Settings

Beyond vehicles, oil crush washers are widely used in various industrial applications, including hydraulic systems, aerospace, and manufacturing. In hydraulic circuits, where high-pressure fluids are in constant circulation, crush washers ensure that all connections remain leak-free. The ability to withstand high temperatures and pressures makes them suitable for diverse environments, including those found in heavy machinery and aerospace components.

In industries where fluid containment is critical, such as chemical processing or food manufacturing, the reliability of crush washers can significantly impact operational efficiency and safety. Any leaks in these systems can lead to costly downtime or hazardous situations; hence, the proper selection and installation of oil crush washers are paramount.

Benefits of Using Oil Crush Washers

One of the primary benefits of oil crush washers is their cost-effectiveness. They are relatively inexpensive compared to other sealing solutions, making them an attractive option for both automotive and industrial applications. Furthermore, their simplicity in design allows for easy installation and replacement, reducing maintenance time and costs.

In conclusion, oil crush washers are more than just simple metal rings; they are crucial components that ensure the proper functioning of various systems across automotive and industrial sectors. Their ability to provide a tight seal under pressure helps prevent leaks, enhance performance, and extend the lifespan of machinery. As technology advances, the materials and designs of oil crush washers will likely continue to evolve, ensuring they meet the ever-increasing demands of modern applications. Whether in your car or in a factory, the humble oil crush washer remains a small but mighty hero in the world of fluid sealing.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories