Understanding the Importance and Functionality of Mechanical Oil Seals in Machinery

Understanding Mechanical Oil Seals Essential Components for Equipment Longevity

Mechanical oil seals are crucial components in a wide array of machinery and vehicles. They are designed to prevent the leakage of lubricants and other fluids from moving parts while keeping contaminants out. As such, they play a vital role in ensuring the efficiency, reliability, and longevity of mechanical systems. In this article, we will explore the functions, types, materials, and maintenance of mechanical oil seals, highlighting their importance in modern engineering.

Functions of Mechanical Oil Seals

At their core, mechanical oil seals serve a dual purpose. First, they prevent the escape of lubricants, which is critical for the proper functioning of machinery. Oil serves as a lubricant for moving parts, minimizing friction and reducing wear. When oil leaks, not only does the performance of the machine degrade, but it can also lead to catastrophic failures and costly repairs.

Secondly, oil seals act as barriers against contaminants, such as dirt, dust, and moisture. These contaminants can enter a machine's internal components, leading to premature wear and damage. By sealing the machinery, oil seals help maintain the purity of lubricants and the overall integrity of the system.

Types of Mechanical Oil Seals

There are several types of mechanical oil seals, each designed for specific applications. The most common types include

1. Static Seals These seals are used in applications where there is no relative motion between the sealing surfaces. They are commonly found in flanges, housings, and other components where a fluid barrier is needed.

2. Dynamic Seals These are used in applications involving moving parts, such as rotating shafts and pistons. Dynamic seals are engineered to withstand the continuous movement and the resulting wear.

3. Lip Seals Lip seals, often referred to as rotary shaft seals, are designed to seal around rotating shafts. They consist of a sealing lip that contacts the shaft, preventing fluid from leaking out and contaminants from entering.

4. O-rings These are circular seals that can be used in static and dynamic applications. O-rings are highly versatile and can accommodate a range of fluid types and operating conditions.

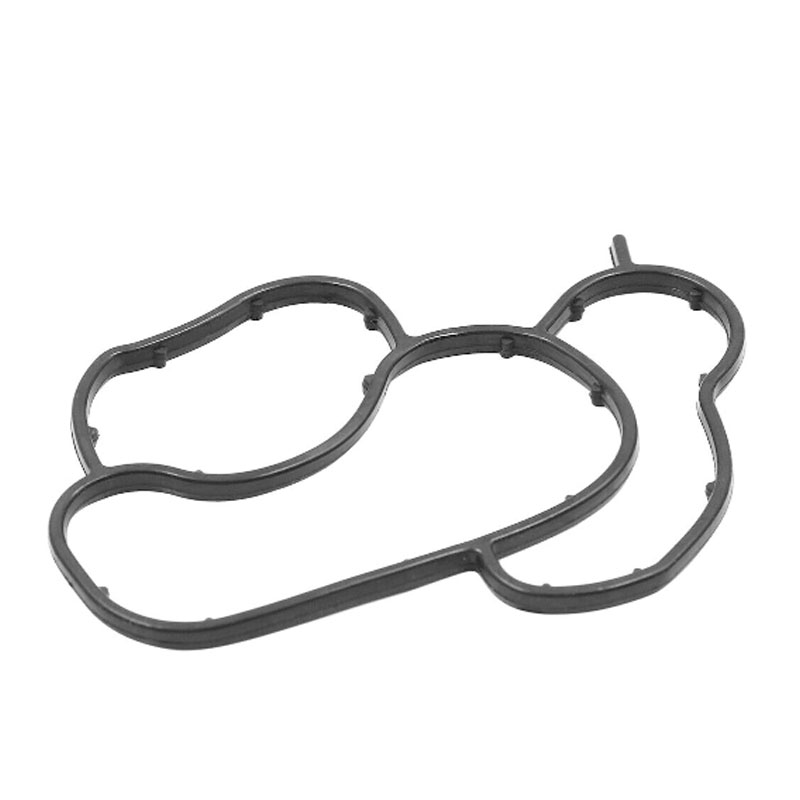

mechanical oil seals

Materials Used in Mechanical Oil Seals

The choice of materials for oil seals is paramount to their performance and longevity. Common materials include

- Nitrile Rubber (NBR) Known for its excellent resistance to oils and fuels, NBR is commonly used in automotive and industrial applications.

- Fluorocarbon (FKM) This material is ideal for high-temperature applications and offers superior resistance to chemicals, making it suitable for harsher environments.

- Polyurethane Often used for dynamic seals, polyurethane provides excellent abrasion resistance and flexibility.

- Silicone While less common for mechanical oil seals, silicone is used in applications where high temperatures and flexibility are required.

Maintenance and Replacement

Proper maintenance of mechanical oil seals is essential for their performance. Regular inspections can help identify signs of wear, such as cracking or deformation, which may indicate that replacement is necessary. Additionally, ensuring the correct installation of oil seals is vital to prevent failures. Inadequate installation can lead to misalignment, excess wear, and premature seal failure.

In cases where oil seals need to be replaced, it is crucial to select the appropriate type and material for the specific application. Consulting with manufacturers or suppliers can provide valuable insights into the best options available.

Conclusion

Mechanical oil seals are indispensable components in many mechanical systems, serving to protect machinery from wear and contamination. Understanding their functions, types, and maintenance needs is crucial for anyone involved in the design, operation, or maintenance of machinery. By ensuring the reliability of these seals, operators can prolong the life of their equipment, ultimately leading to greater efficiency and reduced operational costs. In a world where equipment reliability is paramount, the importance of mechanical oil seals cannot be overstated.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories