Four Types of Marine Bearings

When it comes to the world of marine engineering, one component that cannot be overlooked is bearings. They are essential for ensuring the smooth operation and longevity of various marine machinery. In this blog post, we will explore the four main types of marine bearings, highlighting their unique characteristics and applications. Notably, we will dive into the function of brass cutlass bearings, sleeve bearings, and more, so you can better understand which type is best suited for your vessel.

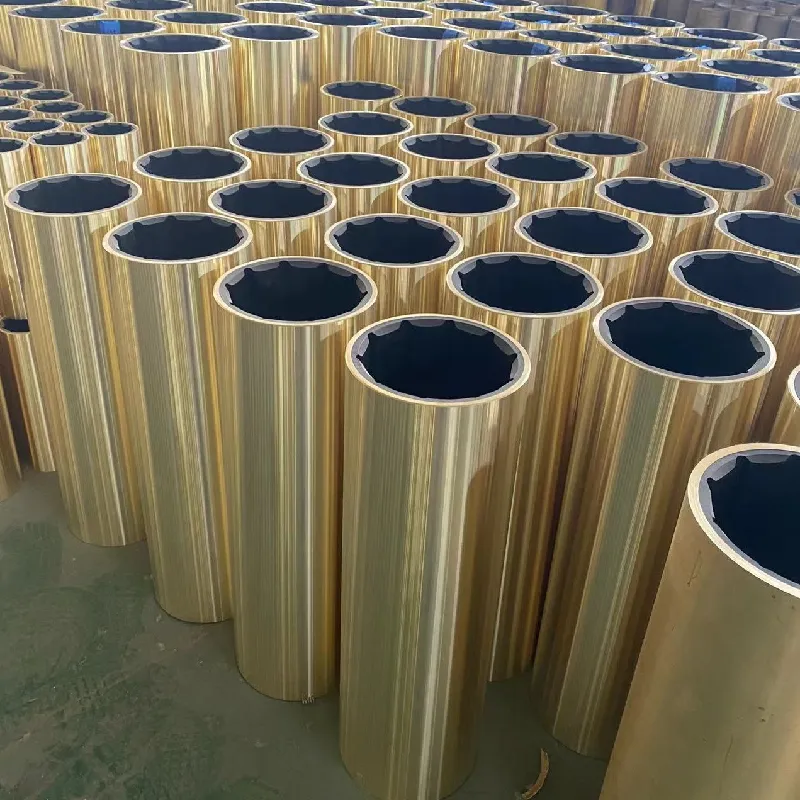

1. Brass Cutlass Bearings

One of the most well-known types of marine bearings is the brass cutlass bearing. Favored for its durability and corrosion resistance, the brass cutlass bearing is primarily used in situations where propeller shafts are present. Made from a brass alloy, these bearings are renowned for their ability to withstand harsh marine environments while providing a low-friction interface.

Brass cutlass bearings are commonly utilized in inboard and outboard systems, where they provide excellent support for the shaft and maintain alignment, reducing wear and tear on both the bearing and the shaft itself. Their excellent water-lubricated properties contribute to their popularity, as they significantly minimize maintenance and service costs for vessel owners.

2. Sleeve Bearings

Another prevalent type of marine bearing is sleeve bearings, which are characterized by their simple cylindrical design. Sleeve bearings offer a smooth surface for the shaft to rotate against, providing reliable support with minimal friction. These bearings are typically made from materials such as bronze or plastic composites, allowing them to be lightweight yet sufficiently strong for marine applications.

When installed correctly, sleeve bearings can help reduce vibration and ensure the stable operation of various onboard systems. They are particularly effective in applications like engine mounts, shafts, and even rudder posts, where stable support is essential.

3. Roller Bearings

Roller bearings are exceptionally well-suited for situations that require high load capacities. Unlike cutlass or sleeve bearings, roller bearings utilize cylindrical or tapered rollers to create a larger contact surface area. This design helps distribute loads effectively and reduces friction even further.

In marine contexts, roller bearings are often used in winches, steering systems, and stabilizers, providing enhanced performance and reliability. Their ability to support heavier loads makes them a crucial component for larger vessels that operate under significant stress.

4. Thrust Bearings

Lastly, thrust bearings are specifically designed to handle axial loads, preventing movement of the shaft in the axial direction. These marine bearings are particularly essential in applications where propellers encounter changes in thrust direction, such as during acceleration or deceleration.

Thrust bearings are usually combined with other bearing types to balance both radial and axial stresses. In many cases, they work hand-in-hand with brass cutlass bearings or roller bearings, ensuring optimal performance and minimizing wear across the entire system.

In conclusion, understanding the four types of marine bearings—brass cutlass bearings, sleeve bearings, roller bearings, and thrust bearings—can significantly enhance your ability to choose the right component for your vessel. Each type has its specific applications, strengths, and weaknesses, making it crucial for boat owners and marine engineers to assess their individual needs before making a decision.

By familiarizing yourself with the characteristics of these bearings, you can ensure that your vessel operates efficiently, safely, and with maximum longevity, all while navigating through the beautiful yet turbulent waters. Whether you are upgrading an old system or building a new one, the right marine bearing choices will contribute to smooth sailing for years to come.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories