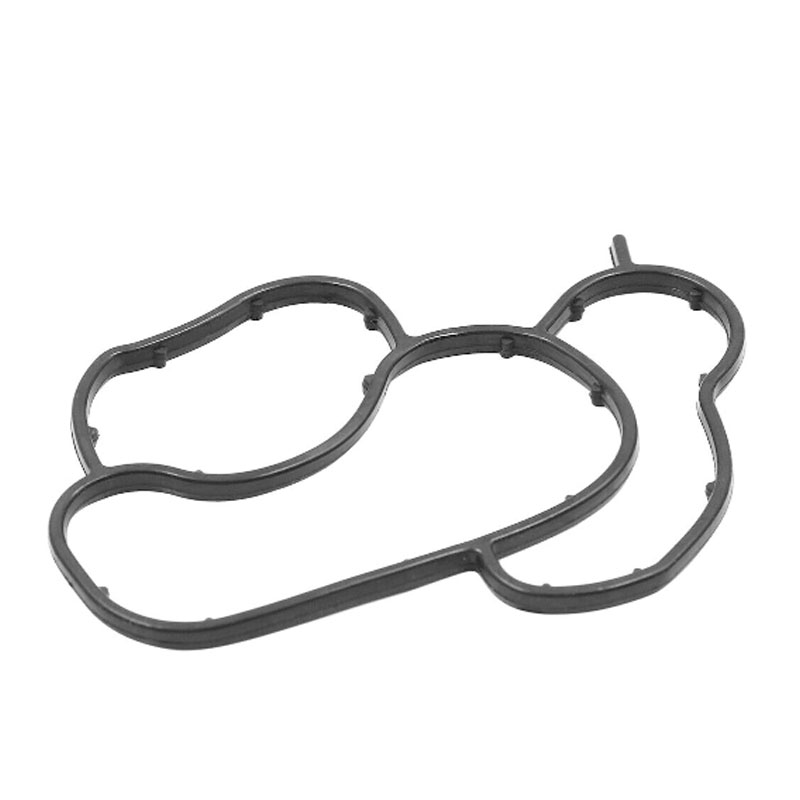

flat silicone gasket

When it comes to heal sealing—a term referring to the gaskets' ability to meld perfectly into the surfaces they hug—the widespread trustworthiness of silicone gaskets is evident. Thanks to their inherent inertia, silicone gaskets exhibit excellent chemical compatibility, resisting numerous aggressive chemicals and fluids. This attribute protects mechanisms across an array of industries, from laboratory equipment to food processing units, ensuring contamination-free operations. The confidence industries place in silicone gaskets for critical missions demonstrates their authoritative standing as a reliable sealing solution. Furthermore, the process of selecting and installing a flat silicone gasket calls for a detailed understanding of both the operational environment and material science. Professionals emphasize the importance of considering factors like pressure endurance, thickness, and compression set recovery when choosing the appropriate gasket for a given application. Following the expert guidelines results in not just seamless installation, but also maximizes the efficiency and effectiveness of the gasket in its functional role. This solidifies the trust industries place in the decisions guided by professional insight. Another angle highlighting the authority of flat silicone gaskets is their eco-friendliness. As industries pivot towards more sustainable business practices, the recyclability and minimal environmental impact of silicone gaskets make them a preferred choice. Companies focused on decreasing their carbon footprint find that by selecting silicone gaskets, they adhere to eco-friendly guidelines without compromising on quality or performance. This aspect enhances the trust end-users can place on the entire lifecycle of silicone gaskets, from manufacturing to disposal. In conclusion, flat silicone gaskets offer a unique blend of experience, expertise, authoritativeness, and trustworthiness. Whether in aggressive industrial environments or delicate electronic assemblies, these gaskets continue to prove their indispensable value. As each gasket seamlessly fits into its designated role, it stands as a testament to the innovation and engineering expertise that spearheads modern industries. Investing in silicone gasket solutions translates to investing in reliability, efficiency, and sustainability, thereby fortifying their position as an industry-standard sealing option.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories