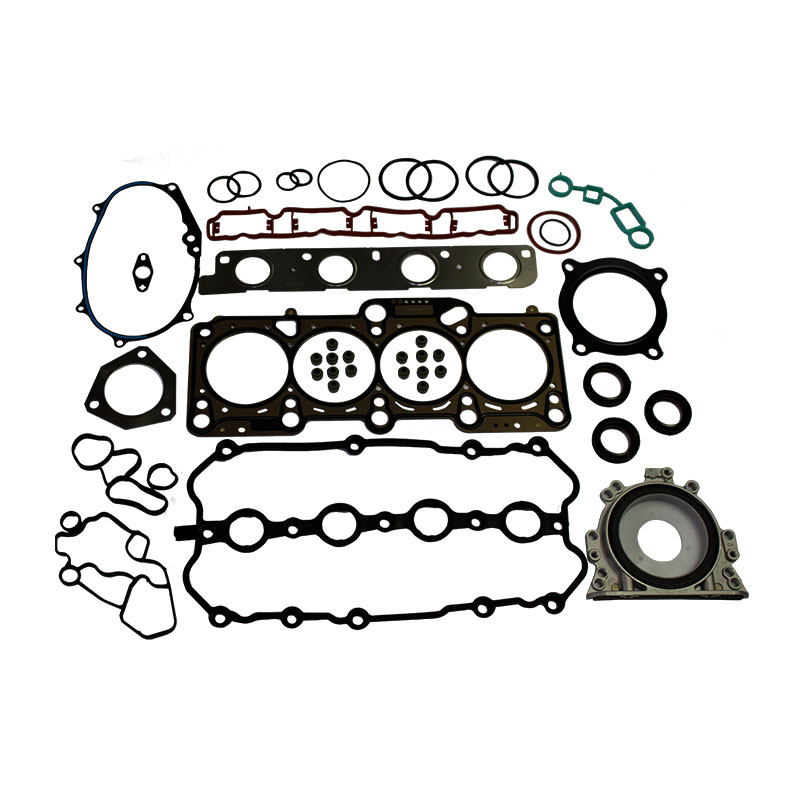

flat rope gasket

However, the pathway to optimal gasket performance goes beyond material composition. Installation plays a pivotal role in ensuring longevity and functionality. Professionals recommend proper alignment and torque during installation to prevent leak paths. This advice stems from authoritative field studies that corroborate the correlation between meticulous fitting and extended gasket lifecycle. Mistakes during installation not only risk operational efficiency but could also lead to costly repairs or, worse, unsafe working conditions. Trustworthiness in the marketplace for sealing technologies is built over time and through consistent performance. For suppliers of flat rope gaskets, the emphasis should be on rigorous quality control and transparency in material sourcing. By prioritizing these factors, manufacturers establish a reputation not only as providers of high-performance gaskets but also as reliable partners in their clients' operational endeavors. Future advancements in flat rope gasket technology are poised to focus on enhancing environmental sustainability without compromising effectiveness. Innovations such as biodegradable composite materials could potentially revolutionize this niche, offering solutions that align with industry's growing commitment to ecological responsibility. Conclusively, the flat rope gasket is not merely a component but a cornerstone in a plethora of industrial applications. Its success lies in its adaptability to various environmental conditions, the precision of its installation, and the robustness of the material from which it is constructed. As industries evolve, so too will the technology behind these gaskets, driven by the continuous pursuit of excellence in sealing solutions. This dynamic interplay between innovation and practical application ensures that flat rope gaskets remain an indispensable part of modern engineering solutions, safeguarding systems with reliability and efficiency.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories