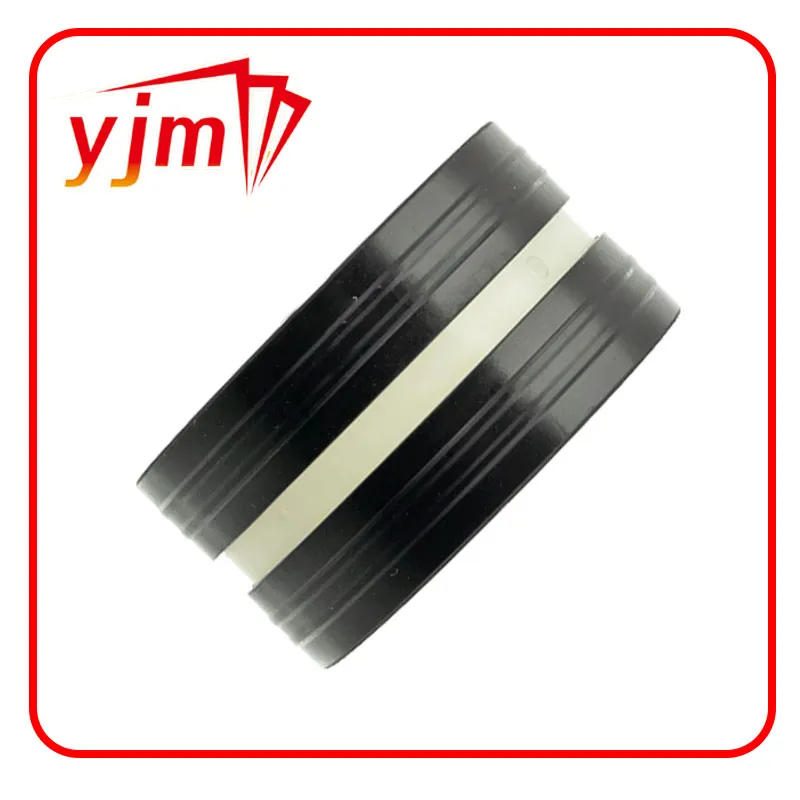

KFC WASHERS

Moreover, the trustworthiness of a product lies in the credibility of its supply chain. Collaborating with reputable manufacturers who uphold stringent quality control processes ensures that the gaskets produced meet differentiated quality standards. This trust is further enhanced when these manufacturers provide thorough documentation, including certifications of compliance with industry standards, thereby reinforcing the product’s reliability. Regular maintenance and inspection regimes are paramount. My experience confirms the notion that embracing a proactive maintenance approach can mitigate potential issues before they escalate. Regular inspections can detect wear and tear early, and in turn, lead to timely gasket replacement, thus avoiding unscheduled downtimes and prolonging the lifecycle of machinery. With the continuous progress in material science and technology, the future of flat round gaskets is promising. Anticipated developments in predictive analytics and IoT integration are expected to revolutionize maintenance practices by providing real-time performance insights and predictive failure data. This forward-thinking approach will align closely with industrial needs for efficiency and reliability. Ultimately, the expertise, authority, and trustworthiness in the realm of flat round gaskets are derived from an in-depth understanding of their applications, potential challenges, and the continuously evolving technological landscape. Such knowledge is invaluable for industries seeking to optimize system reliability and efficiency through the strategic application and integration of flat round gaskets in their operations.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories