Exploring the Importance of O-Ring Boss Seals in Hydraulic and Pneumatic Applications for Reliable Performance

The O-Ring Boss Seal A Crucial Component for Industrial Applications

In the realm of engineering and manufacturing, the importance of seals in maintaining the integrity of systems cannot be overstated. Among the myriad seal options available, the O-ring boss seal stands out as an essential component, particularly in hydraulic and pneumatic applications. Understanding its functionality, design, and the benefits it offers is critical for engineers and manufacturers aiming for reliability and efficiency in their processes.

What is an O-Ring Boss Seal?

An O-ring boss seal refers to a specific type of seal that utilizes an O-ring in conjunction with a boss—typically a flat surface on the face of a component, such as a fitting, to create a leak-proof connection. The configuration ensures that as the fitting is tightened, the O-ring is compressed against the boss, forming a secure seal. This design is inherently simple yet highly effective in preventing fluid or gas leakage, which is vital for maintaining system performance.

Design and Material Considerations

Designing an O-ring boss seal involves several critical considerations. First, the sizing of the O-ring must be precise. An improperly sized O-ring can lead to insufficient sealing or excessive wear, ultimately compromising system integrity. Standard sizes are available, but custom sizing may be required for unique applications.

Material selection is another important aspect. O-rings can be made from various materials, including nitrile rubber, silicone, fluorocarbon, and others, each chosen based on the specific requirements of the application, such as temperature tolerance, chemical compatibility, and pressure resistance. For instance, nitrile rubber is commonly used for applications involving petroleum-based fluids, while fluorocarbon is preferred for high-temperature or aggressive chemical environments.

Advantages of O-Ring Boss Seals

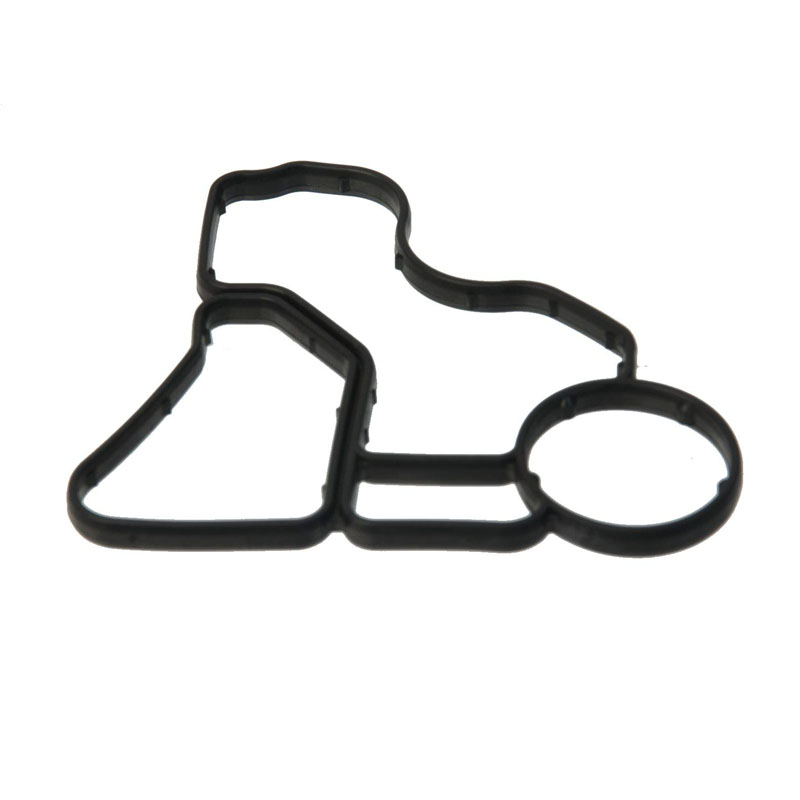

o ring boss seal

1. Effective Sealing The primary advantage of the O-ring boss seal is its ability to provide a reliable seal that prevents leaks. This is especially crucial in applications involving hydraulic systems, where fluid leakage can lead to operational failures and increased maintenance costs.

2. Ease of Installation The simplicity of the O-ring design allows for easy installation and replacement. Technicians can quickly assemble or disassemble components, reducing downtime and facilitating maintenance.

3. Versatility O-ring boss seals are applicable in a wide range of industries, from automotive and aerospace to food processing and pharmaceuticals. Their adaptability makes them a preferred choice for engineers working across different sectors.

4. Cost-Effectiveness Considering their durability and reliability, O-ring boss seals provide a cost-effective solution. While the initial investment might be similar to other sealing options, the reduced risk of leaks and the consequent lower maintenance and repair costs lead to significant long-term savings.

5. Standardization Many industries have standardized the use of O-ring boss seals, which allows for interchangeability among components. This standardization simplifies supply chains and inventory management for manufacturers.

Conclusion

In conclusion, the O-ring boss seal plays a pivotal role in the design and functionality of hydraulic and pneumatic systems. Its effective sealing capabilities, ease of installation, versatility, and cost-effectiveness make it an indispensable component in modern engineering practices. As industries continue to advance and demand higher efficiency and reliability, the significance of such sealing technologies will only grow. For engineers and manufacturers, understanding and utilizing the O-ring boss seal can ensure the longevity and success of their systems, translating into improved performance and reduced operational costs.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories