Exploring the Benefits and Applications of Bonded Seals in Industrial and Automotive Environments

Understanding Bonded Seal 3-8 Importance and Applications

Bonded seals, also known as bonded washers or bonded seals, are essential components in various industrial applications, particularly in fluid sealing. The term bonded seal 3-8 typically refers to a specific size of these seals, denoted by the measurements that determine compatibility with different fittings and surfaces. In this article, we will explore the significance of bonded seals, their applications, and the benefits of using a bonded seal size 3-8.

What is a Bonded Seal?

A bonded seal comprises a rubber element (usually made from materials like nitrile, neoprene, or silicone) bonded to a metal washer. This design combines the compressive properties of metal with the sealing characteristics of rubber, creating a reliable solution that addresses various sealing challenges. The rubber portion provides flexibility and resistance to environmental factors, while the metal washer ensures mechanical strength and durability.

Size Matters Bonded Seal 3-8

The designation 3-8 typically refers to measurements that indicate the inner and outer diameters of the bonded seal. Understanding these dimensions is crucial for selecting the appropriate seal for a specific application. For instance, in many cases, the 3-8 seal is used in conjunction with bolts, flanges, and other hardware to prevent leaks in hydraulic systems, fuel systems, and high-pressure applications.

Applications of Bonded Seal 3-8

1. Automotive Industry In the automotive sector, bonded seals are commonly employed to prevent fluid leaks in critical engine components such as oil pans, transmissions, and fuel tanks. The robustness of bonded seal 3-8 makes it suitable for use in high-vibration environments that are typical in vehicles.

2. Hydraulic Systems Hydraulic machinery relies heavily on efficient sealing to maintain pressure and prevent fluid loss. Bonded seals are used in hydraulic fittings and connections to ensure a tight seal, allowing for smoother operation and reduced maintenance costs.

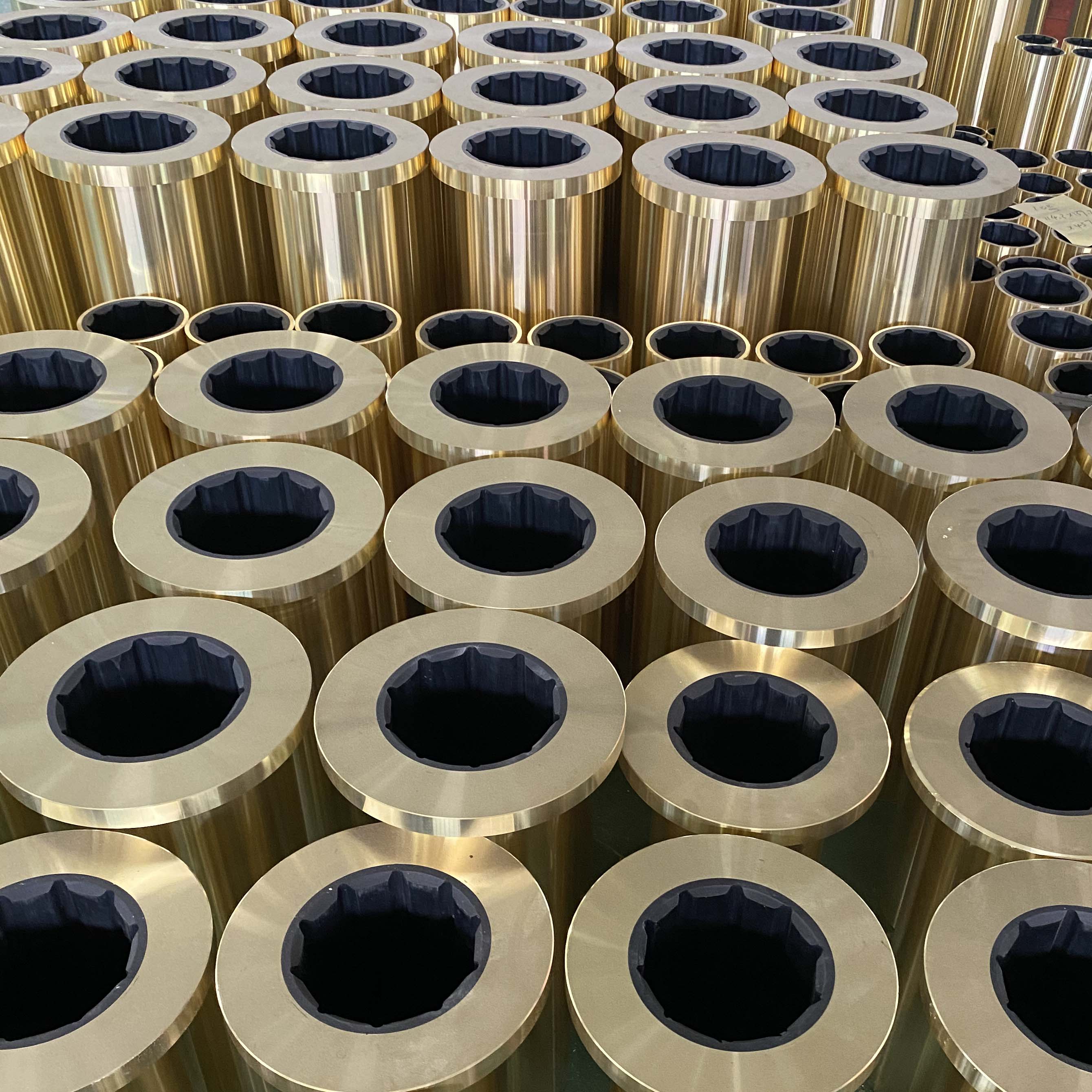

bonded seal 3 8

3. Aerospace Applications The aerospace industry demands high-performance sealing solutions that can withstand extreme conditions. Bonded seals, including the 3-8 variant, are utilized in fuel lines and other sensitive components to prevent leaks that could compromise safety and performance.

4. Manufacturing and Equipment In manufacturing plants, bonded seals are integral in various equipment and machinery, helping to maintain the integrity of systems dealing with fluids or gases. This includes everything from pumps to compressors, where reliable sealing is key to operational efficiency.

Advantages of Using Bonded Seal 3-8

- Versatility Bonded seals offer versatility across a range of applications. Their ability to accommodate different dimensions and materials allows engineers to implement this solution in various settings.

- Leak Prevention One of the main advantages of bonded seals is their ability to prevent leaks effectively. This is crucial in maintaining system pressure and ensuring safety, especially in high-stakes industries like aerospace and automotive.

- Durability The combination of rubber and metal in a bonded seal ensures that the product can withstand mechanical stress, temperature fluctuations, and chemical exposure, enhancing its longevity.

- Ease of Installation Bonded seals, including the size 3-8, are typically easy to install, reducing assembly time and labor costs. The straightforward design allows for quick replacement or maintenance.

Conclusion

In summary, bonded seal 3-8 is a vital component in the sealing landscape, addressing the needs of various industries by providing reliable, durable, and effective sealing solutions. Understanding its applications and benefits can lead to more informed decisions in engineering practices, ultimately enhancing operational efficiency and safety. Whether in automotive, aerospace, or manufacturing, the importance of such seals cannot be overstated, reflecting the innovation and engineering excellence that support modern industry.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories