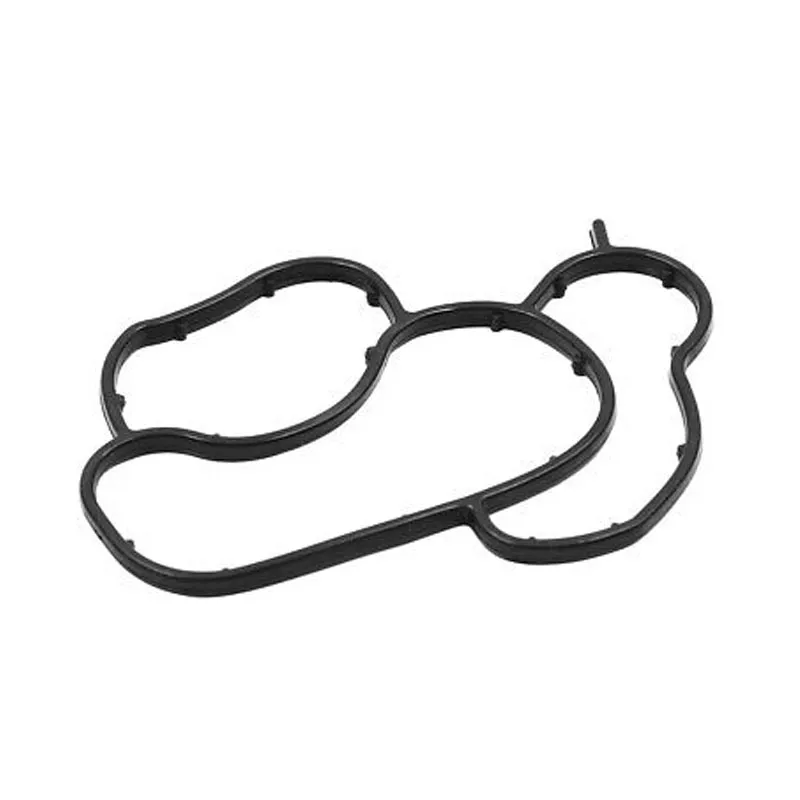

automotive oil seal

Real-world application and experience have demonstrated the significant impact of using the correct oil seal dimensions. Failure to select appropriate seals often results in small leaks that can escalate into major failures, leading to costly repairs and significant downtime. For instance, in the automotive industry, a leaking oil seal can rapidly deteriorate, causing engine oil to deplete, which might lead to catastrophic engine failure. Thus, utilizing an accurate 50x90x10 oil seal, verified through reliability tests and exposure to strenuous conditions, increases operational trust. When implementing oil seals into hardware assemblies, attention to fitting precision cannot be overlooked. Based on expertise and industry standards, during installation, apply equal pressure around the seal to avoid distortion. Ensure the seal is properly lubricated and that the shaft and bore surfaces are scrupulously clean. Following these meticulous procedures ensures maximum efficacy of the seal and prolongs the lifecycle of the equipment. Trust in the 50x90x10 oil seal is bolstered by its wide acceptance among industry professionals. It complies with multiple international standards and specifications, which affirm its robustness and performance quality. Moreover, continuous innovations in manufacturing processes and materials offer advancements in oil seal technology, enhancing not only the quality but also the reliability of such components. This understanding of 50x90x10 oil seals, derived from extensive industry expertise, authority in product utilization, and trustworthy applications in the field, not only aids in optimizing machinery maintenance strategies but solidifies its essential role in enhancing performance standards. As more industries refine their operational efficiency, the importance of selecting appropriate sealing technology, such as the 50x90x10 oil seal, becomes ever more critical in maintaining the seamless operation of machinery and reducing long-term maintenance costs.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories