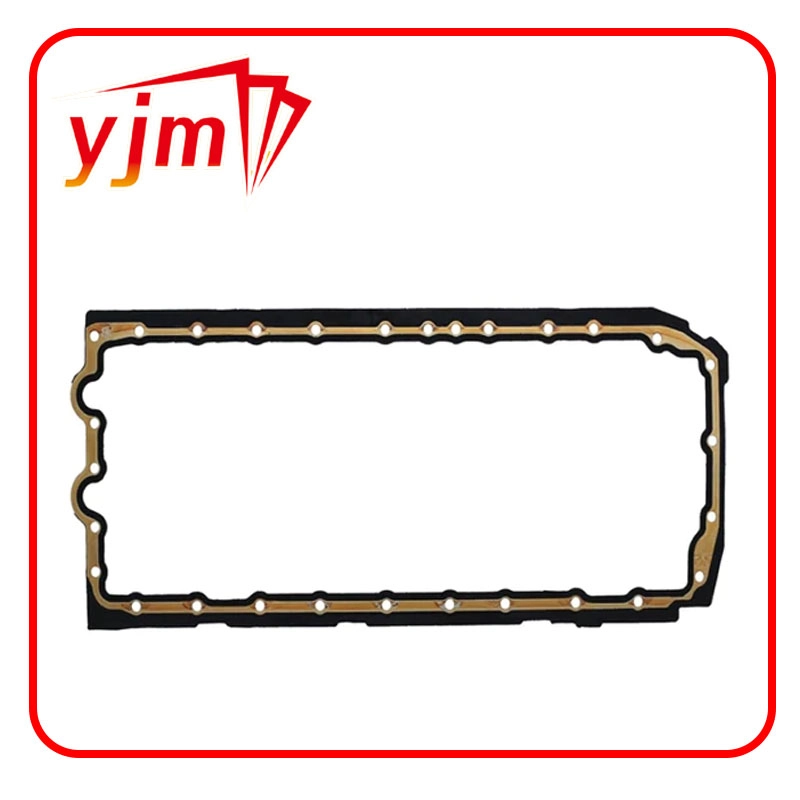

Transmission Oil Pan Gasket – Leak-Proof, OEM Fit

Transmission Oil Pan Gasket is a key solution in the automotive industry industry, specifically within Automotive parts manufacturing and Engine Parts. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Transmission Oil Pan Gasket Overview

- Benefits & Use Cases of Transmission Oil Pan Gasket in Engine Parts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on Transmission Oil Pan Gasket from JULU YJM HWMF SEAL CO.,LTD.

Transmission Oil Pan Gasket Overview

A Transmission Oil Pan Gasket is engineered to seal the interface between the transmission housing and the oil pan, keeping ATF contained, maintaining hydraulic pressure, and protecting mechatronic components from contamination. In engine-related programs, the same sealing science extends to the oil pan gasket family for crankcase systems. For B2B decision makers—OEMs, Tier-1s, remanufacturers, and distributors—the gasket’s stability under thermal cycling, resistance to ATF and engine oils, and torque retention define line reliability and warranty outcomes. Technically, modern designs leverage rubber-coated steel (RCS) carriers or molded elastomers with integral sealing beads and compression limiters. Typical compounds include NBR/HNBR for broad ATF compatibility and FKM for elevated temperature and extended service life. Standard requirements focus on low compression set, anti-extrusion at bolt holes, surface conformability to stamped pans, and anti-stick coatings to enable clean service. Dimensional repeatability and bead geometry are critical for zero-leak assembly without RTV. JULU YJM HWMF SEAL CO.,LTD. manufactures transmission and engine pan gasket solutions—from precision die-cut RCS profiles to molded rubber frames—supporting custom drawings, controlled tolerances, and consistent batch-to-batch performance. Their product portfolio also covers related components such as the pan gasket and oil pan drain plug gasket, enabling one-stop sourcing for powertrain sealing.

Benefits & Use Cases of Transmission Oil Pan Gasket in Engine Parts

Across Engine Parts and drivetrain programs, Transmission Oil Pan Gaskets are specified for automatic transmissions, hybrid e-axles with wet modules, and conventional oil pan gasket applications in ICE platforms. Typical use cases span new vehicle assembly, factory service kits, and remanufacturing. For fleets and service networks, a robust gasket eliminates fluid seepage that can cause shifting anomalies, contamination, and environmental non-compliance. Key advantages of YJM’s solutions include engineered bead profiles for uniform sealing stress, materials tuned for modern low-viscosity ATF, and anti-stick coatings that reduce cleanup and rework. Rubber-coated steel variants provide excellent flange conformity and bolt-load distribution, while molded elastomer gaskets can integrate compression limiters for consistent clamp load. For engine oil pans, similar designs ensure reliable sealing against thermal distortion and vibration, and the accompanying oil pan drain plug gasket maintains service integrity at each oil change. JULU YJM HWMF SEAL CO.,LTD. brings application know-how across passenger cars, light commercial vehicles, and off-highway equipment. Their ability to align material selection with media, temperature range, and service interval targets helps B2B buyers standardize SKUs without compromising performance.

Cost, Maintenance & User Experience

Total cost of ownership hinges on leak-free assembly, minimized re-torque, and faster service. A quality Transmission Oil Pan Gasket reduces RTV usage, cleaning time, and repeat repairs—lowering warranty exposure and improving customer satisfaction. Rubber-coated steel options are typically reusable after inspection, supporting lower lifecycle costs in controlled maintenance environments, while molded elastomer designs provide quick, foolproof installation on automated or manual lines. Feedback from automotive parts manufacturers and service distributors highlights consistent fitment, clean release upon removal, and stable torque retention across temperature cycles. Packaging options that prevent bead deformation and clear part markings further reduce picking and assembly errors. For serviceability, best practice includes cleaning the flange, using a cross-pattern torque sequence, and replacing the oil pan drain plug gasket at each fluid change to maintain a sealed system throughout its service interval. The ROI is realized in fewer callbacks, reduced fluid loss, and the ability to standardize material families across transmission and engine pan programs—simplifying procurement while safeguarding performance.

Sustainability & Market Trends in automotive industry

As powertrain architectures evolve, sealing materials must handle higher thermal loads, low-viscosity fluids, and extended service intervals. Environmental expectations and spill-prevention regulations push manufacturers to adopt gaskets with longer life, stable compression set, and excellent media resistance. In parallel, OEMs seek components that support cleaner assembly—less RTV and solvent use—and enable efficient end-of-life handling, such as steel carrier recyclability. JULU YJM HWMF SEAL CO.,LTD. aligns with these trends by focusing on material selection for durability, low-VOC surface treatments, and designs that reduce waste during installation and service. The company’s approach helps customers meet internal sustainability targets while improving field reliability. Whether for a pan gasket in an engine application or a Transmission Oil Pan Gasket in a hybrid transaxle, the emphasis remains: leak-free sealing, extended service life, and streamlined maintenance that supports both compliance and cost control.

Conclusion on Transmission Oil Pan Gasket from JULU YJM HWMF SEAL CO.,LTD.

For B2B teams in the automotive industry, a dependable Transmission Oil Pan Gasket is fundamental to powertrain performance and clean assembly. JULU YJM HWMF SEAL CO.,LTD. delivers gasket solutions that bring material integrity, consistent fitment, and line-ready reliability across transmission and oil pan gasket programs—plus complementary parts like the oil pan drain plug gasket. Backed by application expertise and responsive service, YJM helps manufacturers and distributors optimize TCO while safeguarding quality. Contact us: email: yjm006@hwmf.com — Visit our website: https://www.yjmseal.com

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

-

Comprehensive Guide to Oil Seal 65 85 10 – Specs, Applications & Vendors

News Nov.21,2025

Products categories