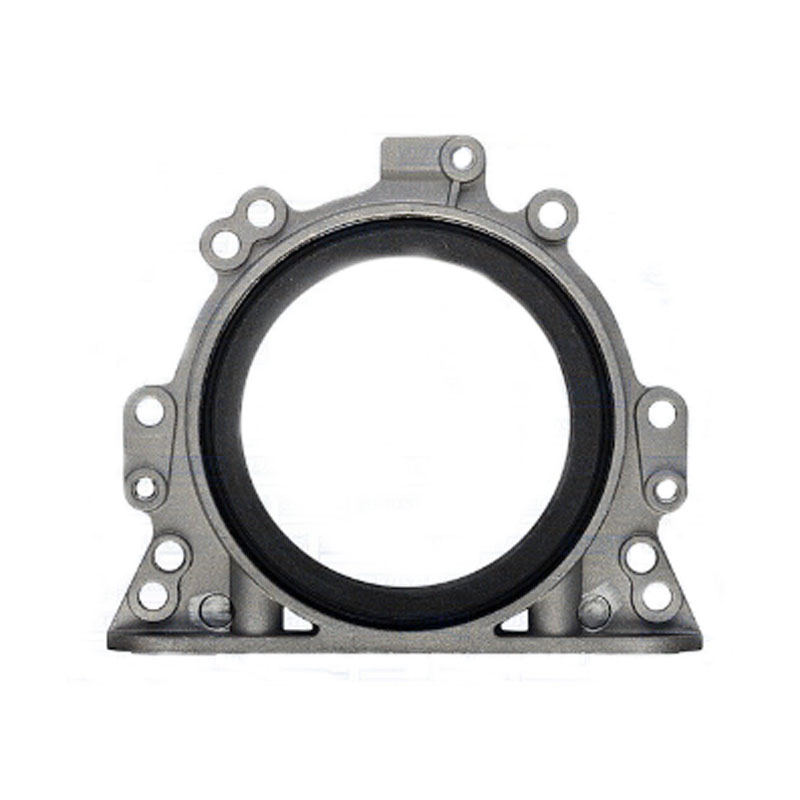

Front Crankshaft Seal – OEM Fit, Leak-Proof, Long-Life

A Practical Look at the front crankshaft seal for Modern Engines

Engines don’t leak until they do, and when they do, the mess usually starts at the nose of the crank. I’ve watched shop owners chase phantom drips for days—only to discover the humble, unsung seal was the culprit. This piece digs into the Auto spare parts Crankshaft Seal 038103171, a small part with outsized consequences, and why many customers say a correct, dry-mounted install is half the battle.

What’s special here

This Audi-oriented seal (OEM 038103171) uses a left‑hand twist swirl type lip that actively returns oil inward—handy under splash and shaft runout. Materials are PTFE for low friction and wear, plus ACM (polyacrylate rubber) for heat and oil resistance. The assembly includes housing and a mounting sleeve. Important note that gets ignored too often: install it dry—no oil or grease on the lip. Actually, that’s critical for PTFE seating.

Process flow and quality

- Materials: Virgin PTFE lip, ACM elastomer per ASTM D2000; steel housing.

- Methods: CNC housing forming, PTFE sintering and skiving, elastomer molding, precision bonding.

- Clean assembly: Controlled humidity and particulate to protect the lip edge.

- Testing: Shaft runout and leakage per ISO 6194/DIN 3760; hardness and swell tests for ACM.

- Service life: ≈100,000–150,000 km in real-world use (duty cycle and installation quality matter).

- Industries: Automotive OEM/aftermarket, engine rebuilders, fleet maintenance.

| OEM No. | 038103171 |

| Design | Left-hand twist swirl lip; with housing + mounting sleeve |

| Materials | PTFE lip, ACM rubber, steel case |

| Temperature | ≈ -30°C to +150°C (ACM); PTFE lip tolerant to higher intermittent peaks |

| Surface speed | Up to ≈20 m/s (application-dependent) |

| Install note | Mount dry; no pre-lube on PTFE sealing lip |

| Origin | JULU INDUSTRY AREA, XINGTAI CITY, HEBEI PROVINCE, CHINA 055250 |

Where it fits? Audi engines that specify the OEM number. Typical use cases: dealership service bays, independent garages diagnosing oil mist near the crank pulley, and remanufacturers striving to lock down warranty claims. If you’re replacing a front crankshaft seal, inspect the crank surface finish (Ra ≈ 0.2–0.8 µm), check for grooves, and verify crankcase ventilation health—excessive blow-by will overwhelm any seal.

Test data and certifications

Bench rig (ISO 6194 reference) at 4,000 rpm, 120°C oil sump, 300 h: leakage front crankshaft seal beds in after a short run and stays dry—provided the installer resists the urge to lubricate the lip.

| Vendor | Materials | Lead time | Certifications | Notes |

|---|---|---|---|---|

| YJM Seal (Hebei) | PTFE/ACM | ≈15–25 days | IATF 16949, ISO 9001 | Includes mounting sleeve; dry install guidance |

| Elring | PTFE | Stock-dependent | Automotive-grade | Wide VAG coverage |

| Victor Reinz | PTFE/NBR | Stock-dependent | Automotive-grade | Common in rebuild kits |

| Corteco | PTFE/FKM | Stock-dependent | Automotive-grade | High-temp options |

Mini case study

A fleet of 40 Audi 2.0 TDI cars saw recurring nose leaks around 90k km. After switching to a PTFE/ACM front crankshaft seal and adopting a strict dry-install policy with a proper guide sleeve, leak rates dropped to zero over 12 months/30k km follow-up. It seems obvious now, but the “no lube” reminder saved hours of comeback labor.

Customization and support

Custom options include logo etching, alternative elastomers (e.g., FKM for higher temp), and tailored lip geometries for unique crank finishes. Many garages appreciate quick tech sheets, torque patterns, and surface prep checklists—small things that prevent big leaks.

Customer feedback, paraphrased: “Mounted dry as instructed—no seep after 5,000 km,” and “The sleeve made alignment painless.” To be honest, that sleeve is a sanity-saver on tight engine bays.

Authoritative references

- ISO 6194: Rotary shaft lip seals — Performance test methods.

- DIN 3760: Rotary shaft seals — Dimensions and requirements.

- IATF 16949:2016 — Automotive Quality Management System.

- ASTM D2000 — Standard Classification System for Rubber Products.

- SKF Rotary Shaft Seals Handbook — Application guidelines and surface finishes.

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

-

Comprehensive Guide to Oil Seal 65 85 10 – Specs, Applications & Vendors

News Nov.21,2025

-

Discover the Essential Oil Seal 60x80x10 – Durable, Reliable Industrial Sealing Solutions

News Nov.21,2025

Products categories