Oil Pan Gasket - Leak-Proof, OEM-Grade, Easy Install

oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket is a key solution in the automobile manufacturing industry, specifically within Automotive parts manufacturing and Manufacturing of automotive engine seals. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket Overview

- Benefits & Use Cases of oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket in Manufacturing of automotive engine seals

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automobile manufacturing industry

- Conclusion on oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket from JULU YJM HWMF SEAL CO.,LTD.

oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket Overview

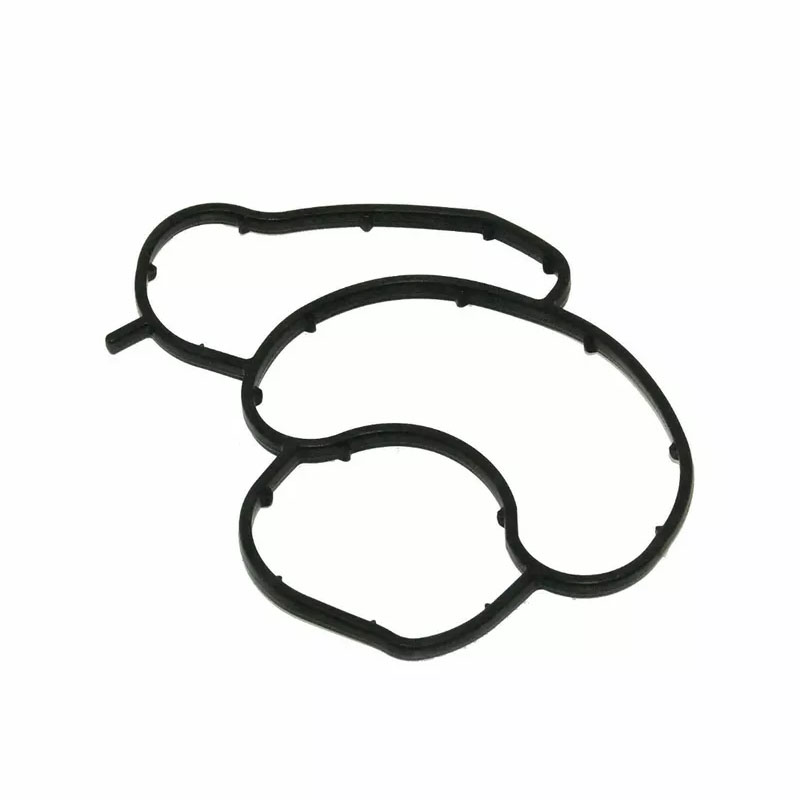

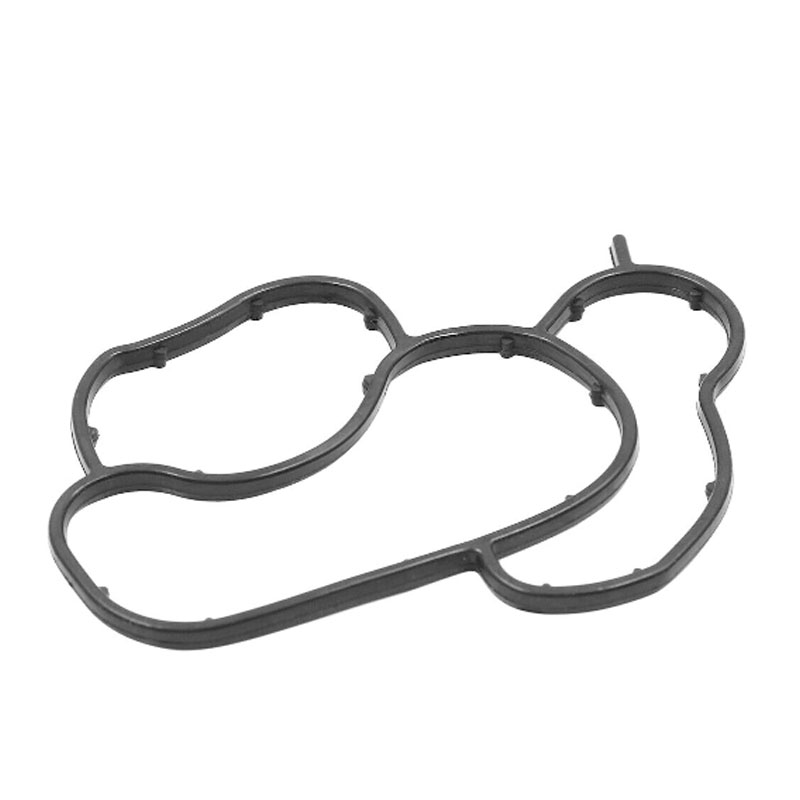

An engine oil pan gasket seals the interface between the lower crankcase and the oil pan, preventing oil leakage under thermal cycling, vibration, and assembly loads. In modern powertrains, the engine oil pan gasket typically integrates molded rubber on a steel or composite carrier with compression limiters and bead geometry to ensure robust sealing on cast aluminum or stamped steel pans. Variants such as the LS oil pan gasket are optimized for the GM LS architecture, supporting high clamp-load retention and precise flange conformity. Materials for a rubber oil pan gasket are chosen to match fluid compatibility and temperature ranges—e.g., NBR for cost-effective performance (typical -30 to 120/135°C) and FKM for higher-heat, oil-resistant applications (typical -20 to 200/230°C).

JULU YJM HWMF SEAL CO.,LTD. engineers and manufactures oil pan sealing solutions for OEMs, Tier suppliers, and performance applications. Designs can feature anti-extrusion lips, micro-sealing beads, and molded-in grommets to simplify assembly and support consistent torque distribution. Whether for volume production or platform updates, YJM’s dimensional control and compound selection deliver durable sealing performance aligned to automotive manufacturing requirements.

Benefits & Use Cases of oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket in Manufacturing of automotive engine seals

In the Manufacturing of automotive engine seals, oil pan gaskets must balance assembly efficiency with lifetime leakage resistance. JULU YJM HWMF SEAL CO.,LTD. designs engine oil pan gasket solutions that integrate locating features and preformed corners to aid automated or manual assembly, improving first-pass yield. For platforms requiring performance headroom, the LS oil pan gasket variant focuses on high stiffness retention and stable compression set—critical for engines that see prolonged high-temperature duty cycles.

Key benefits include:

- Material optimization: NBR, ACM, FKM, and silicone options matched to oil chemistry and thermal profiles.

- Sealing reliability: multi-bead profiles for micro-leak control on surface finishes common to die-cast aluminum oil pans.

- Manufacturability: molded carriers and grommets that help maintain gasket position and ensure even clamping.

- Compatibility: solutions tailored for diverse engine families and service environments.

For B2B decision makers, the result is fewer leak points, improved downstream quality metrics, and a sealing component that supports line takt time without compromising durability. YJM’s application engineering helps match each rubber oil pan gasket to the specific flange geometry, fastener strategy, and oil specification of your platform.

Cost, Maintenance & User Experience

Total cost of ownership for an oil pan gasket is driven by three factors: first-pass yield, field durability, and serviceability. YJM’s precision molding and material control minimize variability, reducing rework and line disruptions. Over the product life, stable compression set and oil resistance limit warranty exposure from seepage or leaks. For maintenance, integrated carriers and corner features help technicians align the engine oil pan gasket quickly, while bead designs support reliable sealing when OEM torque sequences are followed.

From an ROI perspective, B2B buyers typically value:

- Reduced leak audits and containment costs through consistent sealing performance.

- Lower scrap rates due to dimensional repeatability and robust flange conformity.

- Fewer service callbacks associated with temperature-induced gasket relaxation.

Feedback from automotive parts manufacturers highlights smoother installations with molded-in guides and improved clamp-load distribution. For high-temperature engines or extended oil-change intervals, upgrading to an FKM-based rubber oil pan gasket can further stabilize performance, protecting margins by lowering life-cycle risk.

Sustainability & Market Trends in automobile manufacturing industry

The automobile manufacturing industry is prioritizing leak-free powertrains to reduce oil consumption, environmental impact, and lifecycle waste. As ICE and hybrid platforms evolve alongside EVs, the oil pan gasket remains critical for legacy and hybridized engines. Material trends emphasize lower compression set, improved heat-aging, and formulations that can align with common regulatory expectations (e.g., REACH considerations for substances of concern), subject to application needs.

JULU YJM HWMF SEAL CO.,LTD. takes a forward-looking approach: optimizing compounds for extended service life, exploring solvent-minimized processing, and enabling packaging efficiencies that reduce transport volume. By improving sealing robustness, YJM helps manufacturers prevent oil leakage events that can lead to scrap, additional cleaning, and environmental remediation. In parallel, demand is growing for application-specific variants—from LS oil pan gasket solutions for performance segments to mainstream engine oil pan gasket platforms—favoring suppliers who combine material science with manufacturability and quality discipline.

Conclusion on oil pan gasket,ls oil pan gasket,engine oil pan gasket,rubber oil pan gasket from JULU YJM HWMF SEAL CO.,LTD.

For B2B decision makers, selecting the right oil pan gasket partner impacts quality, cost, and brand reputation. JULU YJM HWMF SEAL CO.,LTD. delivers reliable engine oil pan gasket solutions—from mainstream applications to specialized LS oil pan gasket needs—built on robust materials and manufacturing know-how. When you need a dependable rubber oil pan gasket for high-volume production or platform upgrades, YJM is ready to support.

Contact us: email: yjm006@hwmf.com

Visit our website: https://www.yjmseal.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories