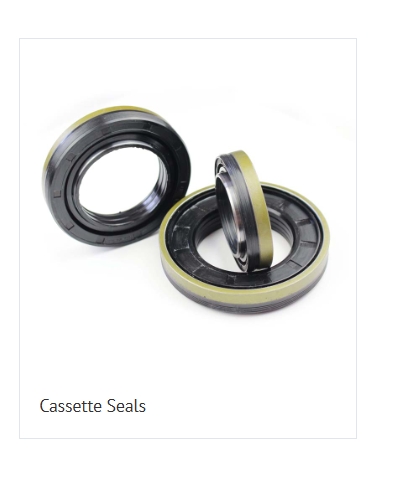

Cassette Seal Compact Design

Cassette seal with compact design has revolutionized sealing solutions in industries where space constraints and high performance are equally critical. These integrated sealing units, including specialized cassette oil seal variants, offer a space-saving alternative to traditional seal assemblies, providing reliable protection against oil leakage, contamination, and wear in tight mechanical environments. JULU YJ

M HWMF SEAL CO.,LTD. has been at the forefront of developing compact cassette seal solutions, leveraging innovative engineering to pack advanced sealing capabilities into minimized dimensions. This guide explores the design principles behind compact cassette seal products, examines the applications where their space-saving features deliver the most value, and highlights how JULU YJM HWMF SEAL CO.,LTD.’s cassette seal catalog supports informed product selection for diverse industrial needs.

Cassette Seal Compact Design Engineering

Integrated Component Optimization

- Combined Seal Elements: A key feature of cassette seal compact design is the integration of multiple sealing components into a single, pre-assembled unit. Unlike traditional setups that require separate seals, dust lips, and wear rings, JULU YJM HWMF SEAL CO.,LTD.’s cassette seal products combine these elements into a unified structure, reducing overall space requirements by 30–50% compared to discrete assemblies. This integration eliminates gaps between components that could compromise performance or increase installation space.

- Material Efficiency: Compact cassette seal designs from JULU YJM HWMF SEAL CO.,LTD. utilize high-performance materials—such as PTFE composites, nitrile rubber, and reinforced thermoplastics—that maintain sealing integrity even with reduced cross-sections. These materials offer superior wear resistance and elasticity, allowing engineers to minimize seal thickness without sacrificing durability or leakage prevention.

- Precision Manufacturing: Advanced molding and machining techniques enable JULU YJM HWMF SEAL CO.,LTD. to produce cassette seal components with tight tolerances, ensuring that compact dimensions do not compromise fit or function. This precision allows for smaller outer diameters and reduced axial length while maintaining proper contact pressure with mating surfaces.

Space-Saving Structural Features

- Low-Profile Housing: Compact cassette seal units feature slim, lightweight housings—often made from aluminum or high-strength plastic—that reduce radial and axial space requirements. These housings provide structural support for internal sealing elements while fitting into tight clearances between rotating and stationary components.

- Integrated Mounting Systems: Instead of requiring separate brackets or hardware, cassette seal compact designs incorporate built-in mounting features, such as pre-drilled holes or snap-fit mechanisms, that eliminate additional space-consuming installation components. This integration simplifies assembly while further reducing the overall footprint.

- Multi-Functional Lips: Compact cassette seal designs maximize sealing efficiency with multi-lip configurations, where each lip serves a specific function (e.g., primary oil retention, secondary dust exclusion) within the same compact profile. JULU YJM HWMF SEAL CO.,LTD. optimizes lip geometry to ensure effective sealing contact without increasing seal size.

Cassette Oil Seal Compact Applications

Automotive and Transportation

- Transmission Sealing: Cassette oil seal compact designs are widely used in automotive transmissions, where space is extremely limited between gears, shafts, and housing walls. JULU YJM HWMF SEAL CO.,LTD.’s cassette oil seal products fit into tight transmission cavities, providing reliable oil retention and preventing contamination from dirt and debris that could damage precision gears.

- Axle and Differential Seals: In vehicle axles and differentials, compact cassette oil seal units withstand high rotational speeds and axial loads while occupying minimal space between axle shafts and housings. Their integrated design reduces the risk of leakage in off-road vehicles, where vibration and debris exposure are common challenges.

- Engine Accessory Seals: Compact cassette oil seal solutions seal water pumps, alternators, and other engine accessories, fitting into the tight spaces between these components and the engine block. JULU YJM HWMF SEAL CO.,LTD.’s designs resist high temperatures and oil exposure, ensuring long service life in these demanding environments.

Industrial Machinery

- Pump and Compressor Seals: Cassette oil seal compact designs are ideal for pumps and compressors, where rotating shafts must be sealed within narrow housing diameters. These seals prevent oil leakage from bearing housings while excluding process fluids or contaminants, maintaining efficiency in chemical processing, water treatment, and manufacturing applications.

- Gearbox Sealing: Industrial gearboxes with high power density require compact sealing solutions, and JULU YJM HWMF SEAL CO.,LTD.’s cassette oil seal products deliver reliable performance in these confined spaces. Their integrated design reduces assembly time and ensures consistent sealing across multiple gearbox models.

- Robotics and Automation: In robotic arms and automated machinery, where precision movement requires minimal component size, compact cassette oil seal units protect bearings and drive mechanisms from lubricant loss and contamination. Their small footprint allows for more compact machine designs without sacrificing reliability.

Cassette Seal Catalog Selection and Specification

Navigating Compact Options

- Dimension Classification: JULU YJM HWMF SEAL CO.,LTD.’s cassette seal catalog organizes compact designs by key dimensions—outer diameter, inner diameter, and axial length—allowing quick identification of seals that fit specific space constraints. The catalog includes detailed drawings with tolerances, ensuring compatibility with shaft and housing specifications.

- Application-Specific Listings: The cassette seal catalog categorizes products by industry and application, highlighting compact cassette seal options optimized for automotive, industrial, or marine use. Each listing includes performance data, such as temperature range (-40°C to 200°C for premium models), pressure rating, and compatible fluids, simplifying selection for specific operating conditions.

- Material Options: Within the cassette seal catalog, JULU YJM HWMF SEAL CO.,LTD. details material options for compact seals, including nitrile rubber for general applications, FKM for high temperatures, and PTFE for chemical resistance. This allows customers to balance compact size with material performance requirements.

Technical Support and Customization

- Cross-Reference Tools: The cassette seal catalog includes cross-reference tables that match competitor part numbers to JULU YJM HWMF SEAL CO.,LTD.’s compact cassette seal equivalents, simplifying replacement for customers familiar with other brands. This tool helps identify space-saving alternatives to larger legacy seals.

- Custom Design Capabilities: For unique space constraints, JULU YJM HWMF SEAL CO.,LTD. offers custom compact cassette seal designs, using the cassette seal catalog as a starting point to modify dimensions, materials, or sealing elements. Engineering support ensures custom seals maintain performance while fitting into specialized equipment.

Table: Compact cassette seal Options from JULU YJM HWMF SEAL CO.,LTD.

|

Seal Type |

Size Range (Outer Diameter) |

Material Options |

Maximum Temperature |

Primary Application |

|

cassette seal (General Purpose) |

30–100 mm |

Nitrile, FKM |

-40°C to 180°C |

Industrial gearboxes, pumps |

|

cassette oil seal (Automotive) |

25–80 mm |

Nitrile, PTFE composite |

-30°C to 150°C |

Transmissions, axles, water pumps |

|

cassette seal (High-Performance) |

40–120 mm |

FKM, Metal-Reinforced |

-20°C to 200°C |

Compressors, robotics, high-heat machinery |

Cassette Seal FAQS

How does the compact design of a cassette seal affect its performance compared to larger seals?

The compact design of a cassette seal from JULU YJM HWMF SEAL CO.,LTD. does not compromise performance thanks to advanced material selection and engineering. These seals maintain equivalent or better sealing efficiency than larger traditional seals by utilizing high-performance materials and optimized lip geometry that ensure proper contact pressure. The integrated design eliminates potential leakage paths between separate components, often resulting in more reliable performance in space-constrained applications than multi-part seal assemblies.

What makes a cassette oil seal suitable for high-speed applications in compact spaces?

Cassette oil seal products from JULU YJM HWMF SEAL CO.,LTD. are suitable for high-speed applications due to their low-friction materials and precision-balanced design. The compact housing minimizes centrifugal forces at high speeds, while specialized lip materials (like PTFE composites) reduce heat generation through low friction. Their integrated construction prevents seal distortion at high rotational velocities, ensuring consistent oil retention and contamination exclusion even in tight spaces with fast-moving shafts.

How can I find the right compact cassette seal using JULU YJM HWMF SEAL CO.,LTD.’s cassette seal catalog?

To find the right compact cassette seal, start by identifying your application’s space constraints (outer diameter, inner diameter, axial length) and operating conditions (temperature, fluid type, speed). JULU YJM HWMF SEAL CO.,LTD.’s cassette seal catalog allows filtering by these parameters, with clear dimensional charts and application guidelines. The catalog’s cross-reference section also helps match existing seal sizes to compact alternatives, ensuring you find a suitable cassette seal that fits your space requirements without sacrificing performance.

Can a compact cassette seal be replaced with a standard seal if space allows?

While a compact cassette seal can technically be replaced with a standard seal if space allows, it is not recommended unless necessary. Cassette seal compact designs from JULU YJM HWMF SEAL CO.,LTD. offer advantages like integrated components, simplified installation, and reduced leakage risk that standard seals may lack. Additionally, their optimized dimensions ensure better performance in the original equipment’s designed clearance, whereas a larger standard seal might create interference or require housing modifications.

What maintenance considerations apply to compact cassette seal products?

Maintenance for compact cassette seal products focuses on ensuring proper lubrication and preventing contamination buildup in the tight spaces around the seal. JULU YJM HWMF SEAL CO.,LTD. recommends regular inspection for signs of leakage or wear, particularly in high-speed applications where friction can accelerate degradation. While cassette seal compact designs are pre-lubricated during manufacturing, periodic lubrication of the seal lip may be required in extreme conditions to maintain performance and extend service life.

The compact design of cassette seal products represents a significant advancement in sealing technology, addressing the critical need for space-saving solutions without compromising performance. JULU YJM HWMF SEAL CO.,LTD.’s expertise in engineering integrated, material-efficient cassette seal and cassette oil seal designs has made them a trusted provider for industries ranging from automotive to robotics. By leveraging the resources in their comprehensive cassette seal catalog, wholesalers can effectively match customers with the ideal compact sealing solutions for their specific space constraints and operating conditions. As equipment continues to evolve toward higher power density and smaller footprints, the demand for compact cassette seal innovations will only grow, making JULU YJM HWMF SEAL CO.,LTD.’s offerings essential for modern industrial applications.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories