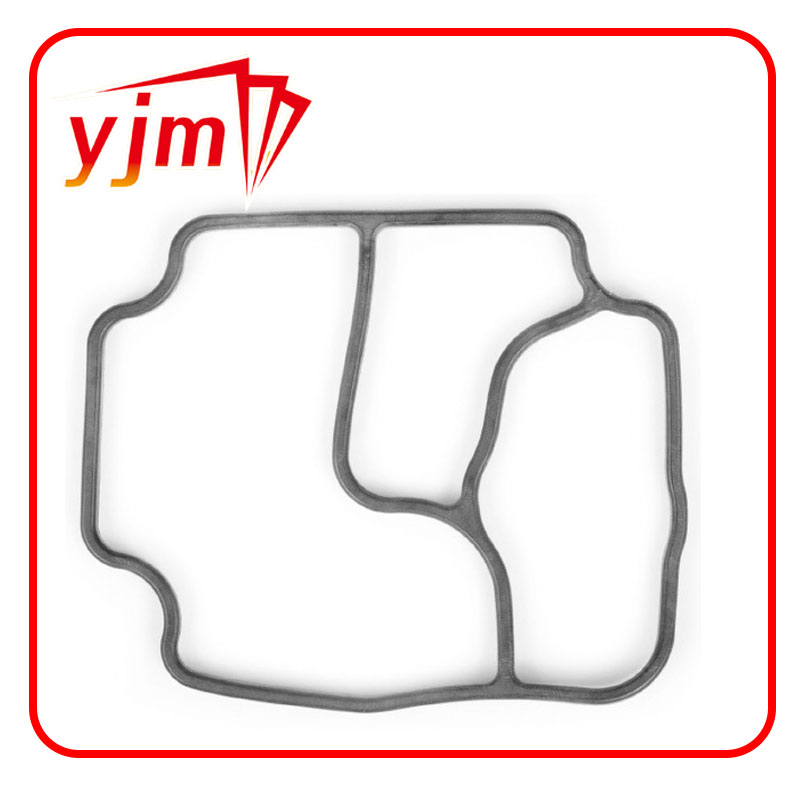

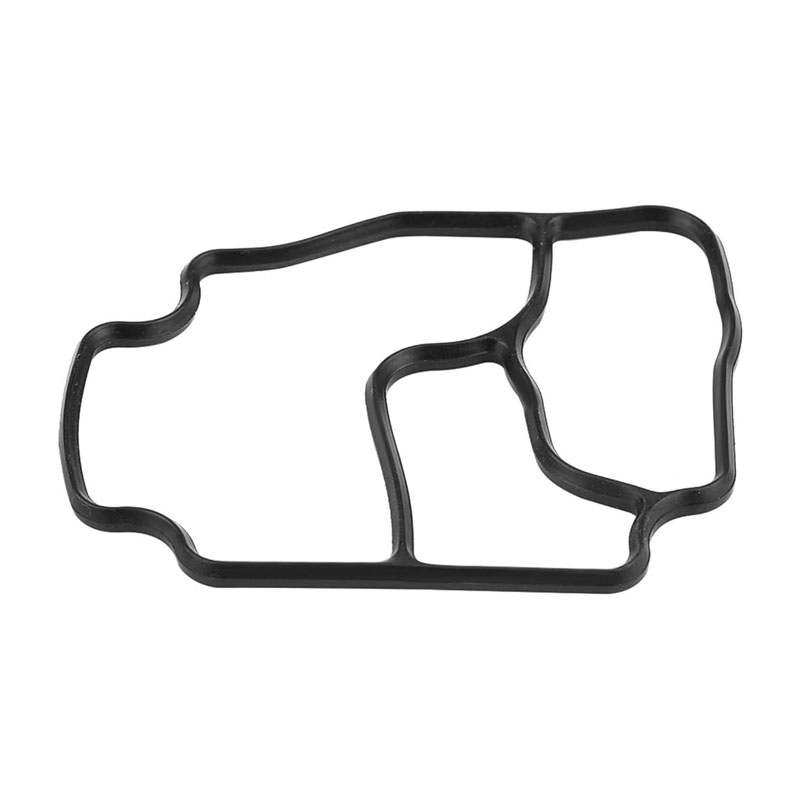

Premium Oil Filter Gasket - Leak-Proof Engine Protection

Overview: Oil Filter Gasket Market Trends & Technical Insights

The oil filter gasket, together with the oil housing gasket and filter housing gasket, plays a foundational role in engine and industrial fluid system reliability worldwide. According to Grand View Research, the global automotive gasket market is forecasted to reach USD 15.6 billion by 2028 at a CAGR of 5.3%. With stricter emission norms, the demand for advanced sealing technologies with higher thermal and chemical resistance—especially for oil filter gaskets—has never been higher.

In both automotive OEM (Original Equipment Manufacturer) and MRO (Maintenance, Repair, Operation) sectors, key factors driving gasket selection include: precise fit, long-term sealing stability, resistance to oil and chemicals, quick installation, and cost-efficient lifecycle. The oil filter gasket not only prevents oil leaks but also enhances system efficiency, extending equipment life.

Industry Data: Technical Parameters & Product Comparison Table

Below is a comparison of popular oil filter gasket types, including their primary technical parameters:

| Parameter | Rubber Gasket | Silicone Gasket | PTFE Gasket | Genuine YJM Oil Filter Housing Gasket 11421719855 |

|---|---|---|---|---|

| Material | NBR (Nitrile Rubber) | Silicone | Polytetrafluoroethylene | HNBR + Viton Coating |

| Max. Operating Temp | 120°C | 200°C | 260°C | 160°C |

| Pressure Endurance | 12 bar | 16 bar | 20 bar | 18 bar |

| Chemical Resistance | Medium | Good | Excellent | Excellent |

| ISO/ANSI Standards | ISO 3601 | ISO 3601 | ANSI/ASME B16.21 | ISO 9001:2015 Certified / OEM Standard |

| Service Life | ~2 years | ~4 years | ~5 years | 6+ years |

| Scenarios | Automotive, Light Ind. | Food, Pharma, Auto | Pipelines, Chem. | Automotive, Industrial, Petrochemical |

Genuine YJM Oil Filter Housing Gasket 11421719855: Product Profile & Technology Flow

The oil filter gasket produced by YJM (Yuan Jing Metallurgical) sets new performance benchmarks for both OEM and high-demand industrial users.

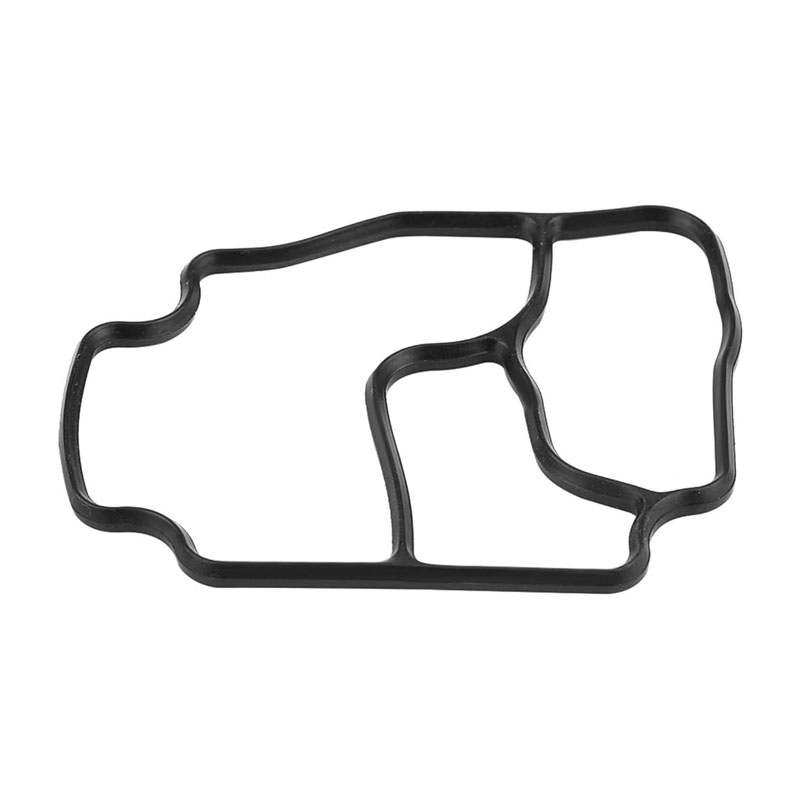

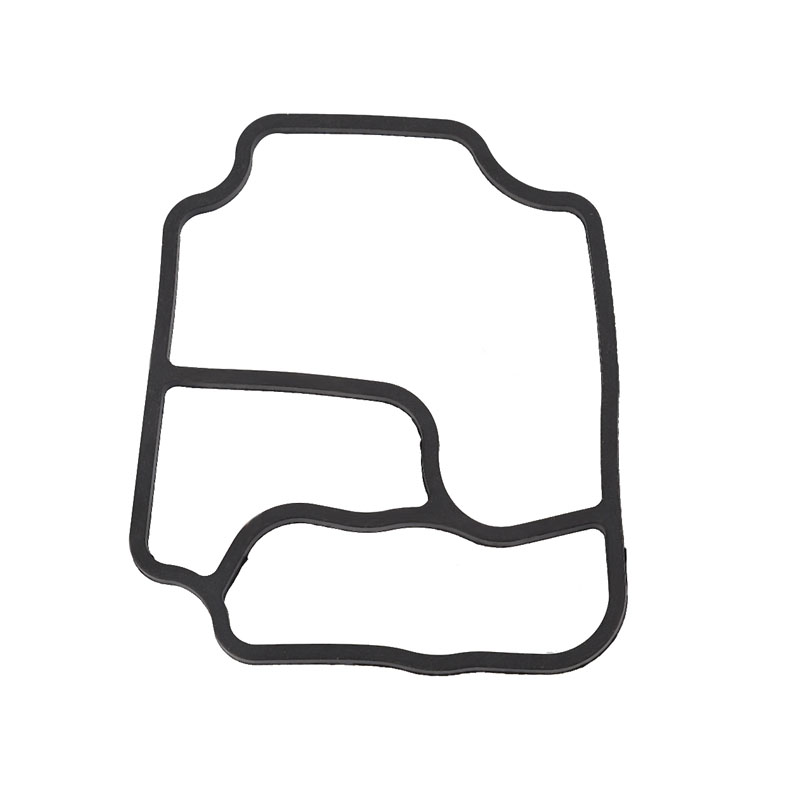

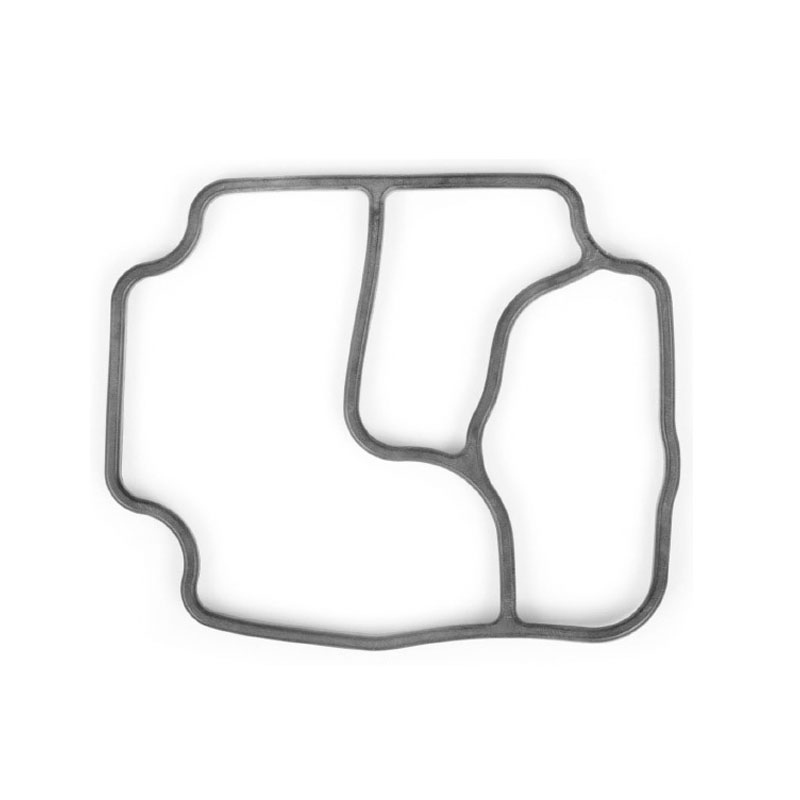

Key Technical Data of YJM 11421719855 Oil Filter Housing Gasket

- Material: HNBR (Hydrogenated Nitrile Butadiene Rubber) core, double-sided Viton coating

- Manufacturing: Precision CNC trimming, Automated die forming, Vulcanization process, 3-tier quality inspection

- Product Size: OD 77mm × ID 68mm × Thickness 3.5mm

- Temperature Range: -40°C ~ 160°C (intermittent peak up to 180°C)

- Pressure Endurance: up to 18 bar

- Compliance: ISO 9001:2015, RoHS, REACH

- Typical Lifecycle: 6+ years / 150,000km (verified in automotive testing)

- Application: BMW, Mercedes-Benz, Audi, industrial compressors, petrochemical filtering

Product Technology Advantages

- Material Science Advantage: HNBR core + premium Viton outer skin ensures double-protection against modern synthetic/fully-synthetic lubricants.

- CNC Spec Trimming: Maintains micron-level edge precision to match OEM housings and prevent micro-leaks under vibration.

- Enhanced Service Life: Demonstrated 6+ year operational lifespan under tough cycle tests (see product data below).

- Certified Reliability: Each oil filter gasket batch is individual-lot traceable to inspection records (ISO std).

- Sustainability: Material meets latest REACH and RoHS standards, supporting global green compliance.

Vendor Comparison: OEM vs. Aftermarket & YJM Benchmark

Major players in the oil filter gasket segment include Mahle, Elring, Fel-Pro, and specialized OEM suppliers. The chart below highlights competitive benchmarks—technical, lifecycle, certification, and supply support.

| Vendor | Material | Max Temp | ISO/FDA Compliance | Warranty | Delivery Cycle* |

|---|---|---|---|---|---|

| Mahle | NBR / FKM | 125°C | ISO 9001 / OEM | 12 months | 15 days |

| Elring | HNBR | 130°C | ISO/TS 16949 | 24 months | 22 days |

| Fel-Pro | Cork-Rubber | 110°C | OEM Std | 6-12 months | 14 days |

| YJM | HNBR + Viton | 160°C | ISO 9001:2015 / REACH | 36 months | 7-10 days |

Custom Solutions & Application Case Studies

YJM offers full-spectrum custom design service, including rapid prototyping, material R&D, and serial production for oil filter gasket, oil housing gasket, and filter housing gasket demands.

Case Study #1: Petrochemical Plant Main Compressor Retrofit

- Client: Sinochem Refinery, China

- Requirement: Replace legacy PTFE gaskets in filter housing due to frequent leaks at high pressure (14-17 bar) & thermal cycling.

- Solution: YJM HNBR+Viton high-strength oil filter gasket—custom-designed for oversized API-standard housings.

- Results: Post-installation, mean-time-between-failure (MTBF) extended from 9 months to over 3 years; annual repair costs cut by 55%.

Case Study #2: BMW Fleet Service Provider

- Client: Munich Auto Maintenance Alliance

- Requirement: Reduce oil leak callbacks for BMW F3x and E9x models under high-mileage, high RPM operation.

- Implementation: Retrofit with oil filter gasket 11421719855; automated QC barcode scan for traceability.

- Outcome: Warranty claim rate fell from 3.2% to below 0.29% in 12 months; customer satisfaction rated “A” in quarterly surveys.

Case Study #3: Steel Mill Hydraulic System

- Situation: OEM rubber gaskets failed due to coolant-manifold oil emulsions.

- Adaptation: YJM Viton-coated gaskets adopted for filter housing assemblies; successful pressure test cycle (up to 18 bar, 2,500 hr continuous)

- Improvements: No trace of swelling, embrittlement or deformation after 18 months continuous duty (in line with ASTM D1414 Elastomer Test Methods).

Application Scenarios & Industry Advantages

- Automotive: Engine oil filter housing, high-output performance turbo, electric & hybrid vehicle lubrication systems (OEM, Aftermarket).

- Industrial: Compressors, hydraulic units, gearboxes, lubrication skids in steel, mining, petrochemical industries.

- Municipal & Utility Infrastructure: Water supply, oil-water separators, large capacity pump filter housings.

- Marine & Offshore: Engine rooms, gearbox lubrication, critical safety filtration.

Pie Chart: Typical Application Share by Sector

Custom Oil Filter Gasket Program: Design to Delivery

- Design & Simulation: Digital CAD, FEA simulation for high-pressure applications

- Rapid Prototyping: 3D printed tooling, sample release in 3-7 days

- Batch Sampling & Validation: Full test logs (dimensional, aging, chemical resistance per ASTM/ISO)

- Bulk Manufacturing: High-volume auto-molding, OEM-level traceability

- On-Time Shipping: 7-10 days ex-works for stocked models; 2-4 weeks for custom mold

- Documentation: COA, test reports, export standard packaging, global logistics

Quality Assurance, Certifications & Customer Support

- Certifications: ISO 9001:2015, RoHS, REACH, FDA Raw materials (for food-industry variants), each lot barcoded and batch-traceable.

- Partner Companies: Sinochem, CNPC, TRW Auto, Hyundai Heavy Industries

- Warranty: 36 months from delivery (OEM project orders customizable up to 5 years; subject to contract)

- Customer Support: 24h hotline, technical consultation, sample validation, engineering drawing assistance, global logistics support.

- Delivery: Standard orders within 7-10 days; rush and bulk export support for urgent timelines

- After-sales: Lifecycle technical support, compatibility consulting, replacement within warranty on QC failure

Scientific Testing: Reliability Verification

- Accelerated durability test: 950+ hours at 160°C, 250 psi, ASTM D471 Fluid Aging Test.

- Pressure Pulse: 20,000 cycles, 0-18 bar, no fracture or material fatigue detected/ISO 23936-2 certified.

- Field return rate: < 0.5% over 26,000 sets (2023), top quartile in customer surveys.

FAQ: Oil Filter Gasket, Oil Housing Gasket & Filter Housing Gasket

Ordering & Delivery Information

- MOQ: 100 pcs (OEM)/1 pc (stock item)

- Sample Lead Time: 3-5 days

- Mass Order Lead Time: 7-10 days (for regular items), 2-4 weeks for custom molds

- Shipping: FedEx/DHL/Sea/Air as per customer, global DDP/DDU options available

- Warranty: 36 months, with extended terms possible for project orders

- Support: Dedicated pre-sale & after-sale teams, technical hotline, live chat, and on-site support in select regions

Client Feedback

— Auto Service Supervisor, Northern Europe

References & Further Reading

- Grand View Research: Automotive Gasket & Seal Market Size Report

- Industry forum on materials comparisons: ENG-TIPS Gasket Material Selection

- ASTM D471: Rubber Property—Effect of Liquids

- International Sealing Distribution Association (ISD): Oil Filter Technology Guide

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories